Beams and columns are an important part of any home’s structure. As architectural styles change, trending to larger open spaces and higher ceilings, with more complex roof designs, the need for beams becomes greater. But those beams don’t always look attractive, especially in areas of the home which were not originally finished, so the builder was not concerned about finishing them in an attractive manner. Later, when that space is finished out to be an additional room, the beams have to be dealt with.

This sort of situation is very common with basements. Most homes are designed by the architect to have a central beam or structural support wall running down the middle of the home, the long way. This exists on every floor and is in line with the roof peak. It can become problematic when finish a basement, because it cannot be removed. It has to either be covered up or integrated into the space’s design.

Many shorter structural beams are nothing more than a couple of 2”x 10”s or 2”x 12”s nailed together. Longer ones are more likely to be made of LVL (laminated veneer lumber), an engineered wood product which is essentially thick plywood, made in a size that will support the weight needed, over the span that the beam needs to cover.

As beams are always structural elements, removing them can be catastrophic to the home. Some homes may survive this at the beginning, but begin to sag over time. Damage from removing beams can be extremely difficult and therefore expensive to repair. At times, it requires removing portions of the roof or upper story and rebuilding them. The “best case” is that whatever was originally supported by the beam will have to be jacked back into place and the beam replaced. Personally, I wouldn’t count on that best case scenario.

The question becomes what to do with a home that has an unsightly beam in it, to make the beam and the home more attractive?

Move the Beam

Some people just don’t like the looks of beams at all in their home or it doesn’t go with their décor. No methodology for improving the appearance of those beams is going to satisfy the homeowner. In that case, it may be necessary to move the beam, if possible.

There are a couple of different ways of moving the beam, depending on the situation. Expect to pay a carpenter $50 to $200 per foot to do the job. For woodworkers doing the job themselves, LVL beams cost $3 to $12 per linear foot. In addition to that, there will be a need to buy joist hangers or hurricane straps, as well as other hardware and finish items.

If the beam is being moved from a point below the attic, the new beam can be placed in the attic, attached vertically to the bottom stringer on the trusses. This might be done in a case where two bedrooms are being combined to make one larger room. The new beam must be installed, before the old beam or header is removed.

The beam should run all the way to the outside wall or to a support column at both ends. If no support column is available, nail two 2”x 4” studs together and hide them in the wall, fitting snugly in the space between the floor plate and the ceiling plate, underneath the end of the new beam. Attach the bottom stringer of the rafter to the new beam with hurricane clips, nailing through all the holes in the clip. It may also be necessary to sister a section of the bottom stringer of the rafter, if it is in two pieces and one of those pieces will be unsupported by the new beam. When sistering, be sure to use equal size material as the stringer and go at least four feet past the joint on either side.

The other way of moving a beam to hide it is used in cases where the beam is supporting floor joists for a floor above the space that the beam currently occupies. As with the case of the roof truss, the new beam should be installed and the floor joists attached to it, before support is removed. As the new beam will probably occupy space directly above the existing beam, it will be necessary to build temporary supports for the joists, a couple of feet back from the beam, so that the old beam can be removed. Then the work to install the new beam can be undertaken.

In order to make this work, the ends of the floor joists are going to have to be cut back just enough to allow the new beam to be set in between them. This usually means cutting the ends of all the joists back about 1-3/4”. The beam is then installed, including the necessary supporting columns at both ends. Once it is in place, joist hangers can be used to attach the floor joists to the beam. As with the hurricane clips used for the truss, be sure to nail through all the hole in the joist hangers.

Wrap the Beam

It isn’t always possible or practical to move a beam; hence we get to the point of this article, wrapping the beam. This generally consists of attaching thinner wood around the existing beam and finishing that wood in such a way as to make the beam look like a more massive, solid wood beam. Depending on the look desired, this can be finished nicely, like the rest of the home’s wood trim or finished in a rustic manner, making it look like it has been there for 100 years or more.

One option where it can be extremely good to wrap a beam is when there are plumbing, electrical or other lines alongside the beam which would be difficult to move. In that case, the wrap around the beam can be done in such a way as to include space for those items, making the beam look more massive and effectively hiding them.

If only the beam is to be wrapped, the wrapping layer of wood can often be attached directly to the existing beam. However, in the case where there are electrical or other lines that need to be covered up, blocking may have to be attached first, to provide something to nail the beam wrap to. If this is necessary, use the same rules as for blocking to support drywall, ensuring that there is sufficient support for all edges of the wood being applied as a wrap.

As for the wrap itself, pretty much any wood can be used, such as standard 1” dimensional lumber or laminate wood floor covering. Some people like using reclaimed wood, so as to provide a rustic look. Reclaimed barn wood is a popular look, although the barn wood can be hard to find. One alternative is reclaimed cedar fencing, which is much more readily available. Rough cut cedar is another popular option, as the coloration of the wood makes for a very attractive beam.

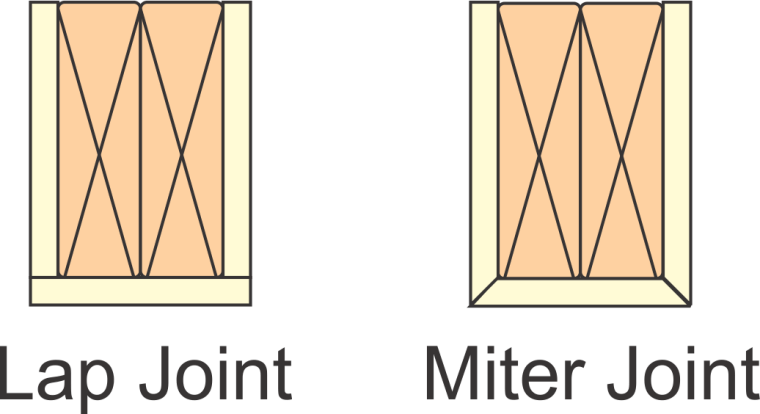

It is important to use wood that is long enough to span the full length of the beam for any wrap. Beams cannot have butt splices in the middle, so any splice in the wrap would destroy the effect that it is all one solid piece. When preparing and installing the wood, the wood added as a wrap can either be lap jointed at the corner or miter jointed. While miter jointing is more difficult, considering that the miter has to be cut the full length of the beam, it does a much more realistic job of hiding the fact that an existing beam has been wrapped, rather than it being a solid wood beam.

Cutting such a miter requires some careful work on the table saw. However, most table saws allow for tipping the blade up to 45 degrees, making it possible to set the saw up to rip this long joint. Rather than trusting the angle gauge on the saw though, I’d recommend using a digital level and angle gauge, the square type, with a magnetic base so that it can be attached to the blade. This will provide a much more accurate miter, helping to eliminate any potential problem with a gap. As the board will be wider at the top, when cutting the miter, there is no risk of it binding up between the blade and the fence.

Once the pieces have been cut, they can either be assembled right to the beam or assembled outside and then brought into the room and attached to the beam. If they are to be assembled outside, be sure to make the wrap slightly oversize to accommodate any irregularities in the beam itself. It will also be necessary to make it about ¼” too short, so as to be able to jockey it into position. Use finish nails and wood glue for assembly and to attach the wrap to the beam.

One of the reasons why one might want to assemble the wrap outside and then bring it into the room to attach to the beam is to avoid the risk of damaging carpeting and furniture during the finishing process. If the beam wrap is to be distressed in any way, the process will probably create a lot of sawdust. Stains and varnish can be destructive to furniture and carpeting as well. While drop cloths can be used, finishing the beam wrap elsewhere can eliminate the risk of making a mess.

Add More Beams

While wrapping an existing beam with wood will make it look considerably better, it may still look out of place, especially if it is the only beam in the room. This problem can be camouflaged by adding additional fake beams to the ceiling of the same room.

There are two basic plans to consider for adding fake beams. The first is to run beams parallel to the existing one, at regular intervals. Even one additional beam will improve the overall effect, but in a large room, several beams will look better.

An alternative to this is to make what is known as a coffered ceiling. This is essentially the same idea as adding additional faux beams, with the exception that crossbeams are added as well, making squares in the ceiling. Such a look was fairly common in fine homes and offices in the past, so it can make a home look much richer.

To add additional beams, whether simple beams or making a coffered ceiling, the additional beam wraps will have to be made outside or in the workshop. Blocking will need to be added to the ceiling, with fasteners going through the block and the ceiling drywall up to the joists in the ceiling. The beam wrap can then be attached to these blocks, making it secure.

Making Exposed Rafters Attractive

A similar situation exists when the exposed floor joists are the ceiling joists or rafter for a room below, such as is commonly encountered when finish a basement. One of the more common ceiling finishes in such cases is to use a suspended ceiling. But many basements don’t have a lot of headroom, so taking even a couple of inches out to put in a suspended ceiling can be problematic. It’s not just the physical loss of space that’s concerning, but the visual impression of a ceiling that seems to be coming down on you.

One solution for this is to treat the floor joists like beams and wrap them with wood. However, if the joists are solid wood, rather than I-beams, and the wood looks good, it might be possible to leave them exposed. staining them could dress them up considerably, without the work and expense of wrapping them. Either way, there’s still the problem of the underside of the floorboards for the floor above. In most homes today, that’s going to be OSB, although some homes may be CDX plywood. Either way, it’s not going to be attractive, regardless of how the joists look or whether they are wrapped. There may even be nails protruding down through the floor.

This can be turned into a very attractive, rustic ceiling by cutting pieces of 1”x 6” or 1”x 8” whitewood dimensional lumber and fitting them crosswise between the existing floor joists. If there are nails poking through the existing floorboards, either cut them off or glue a layer of Styrofoam insulation in place, before installing the wood pieces. The insulation will also provide some sound deadening between floors, quieting down noisy walking on the floor above, while the boards give the impression of the way that floors were done before plywood was invented.

Wrapping Exterior Beams

Exterior beams, such as those over patios, can be treated in much the same way as interior ones, with a couple of notable differences. First, the sides of the beams aren’t usually covered with 1” dimensional lumber, as discussed above; T-111 siding or tongue-and-groove boards are typically used. These pieces can be installed either before or after capping the bottom of the beam. Installing them before can make it easier to fit them in, especially if they have to fit into a slot at the top due to other parts of the structure; but installing them afterwards makes it easier to ensure that the bottom edge is even with the edge of the beam, so that they fit snugly up against the bottom cap. Any gaps at the top can be covered with a piece of trim.

The other notable difference with wrapping exterior beams is that the bottom cap on the beam will usually be wider, leaving a ledge on either side of the beam. This is mostly aesthetic, but also helps to ensure a good seal between the bottom cap and the sides, when caulked. Caulking the type of seam that would exist if the bottom cap was only the width of the beam and the wrap on the sides would create a caulked seam that would eventually open up, allowing moist inside.

While the ledge formed from making the bottom cap piece wider does provide an actual service, I would recommend against making it very wide. All that’s needed is ¼” on each side. If it is any larger, it has been my personal experience that rats and mice can use it as a pathway. I have killed a number of rats, which my dog has found walking on that ledge.