If you’ve ever stood in the lumber aisle at a home improvement store scratching your head over terms like timber, lumber, and wood, you’re not alone. Even seasoned DIYers and woodworkers sometimes mix them up. While these words are often used interchangeably, they mean different things, and knowing the difference can save you time, money, and confusion.

In this guide, we’ll dive deep into the timber lumber wood difference, explain where each term is used, and show you how to choose the right product for your next project.

What Is Wood? Understanding the Role of Wood in the Timber Lumber Wood Difference

At its core, wood is the fibrous material that comes from trees. It forms the structure of a tree’s trunk, branches, and roots. When trees are cut down and processed, we start referring to the harvested material as timber or lumber, but before that transformation, it’s all just wood.

Wood is the general term used when describing the natural substance in its raw form or when talking broadly about woodworking. You’ll often hear someone say they’re “working with wood” even if they’re technically using plywood or finished boards.

What Is Timber? Defining Timber in the Timber vs. Lumber vs. Wood Debate

Here’s where it gets interesting. In the United States, timber typically refers to trees that have been felled but not yet milled into boards. Think of logs sitting in a lumberyard or fresh-cut trunks waiting to be processed. It can also refer to large beams used in construction, especially in timber framing or log homes.

Common Uses of Timber:

- Log cabin building

- Timber frame homes

- Landscaping timbers

- Large support beams

If you’re buying timbers, you’re usually looking at wood with a minimum dimension of 5 inches in thickness or width.

🪚 Affiliate Pick:

👉 Timber Framing Chisels on Amazon – For heavy-duty joinery work on large beams.

🔗 Related Post: How to Cut Your Wood Slabs

What Is Lumber? Clarifying the Difference Between Timber and Lumber

Now let’s talk about lumber—a term every DIYer knows well. Lumber refers to milled wood that’s cut into standard sizes and used in construction and woodworking. This is the wood you find in 2x4s, 2x6s, and other dimensional formats at your local hardware store.

Characteristics of Lumber:

- Typically softwoods like pine, spruce, and fir

- Sold in dimensional sizes (e.g., 2×4, 2×6, 4×4)

- Usually surfaced smooth (S4S: sanded four sides)

- Used for framing, decking, fencing, and DIY projects

📌 Note: Lumber that’s been surfaced smooth and dried is often labeled “dimensional lumber.”

🪵 Affiliate Picks:

- 👉 Lumber Rack Storage Systems – Keep your shop organized.

- 👉 2×4 Basics Workbench Kit – Great for building your bench from dimensional lumber.

🔗 Related Post: How to Build a DIY Crate Bookshelf

Timber vs. Lumber vs. Wood: Quick Comparison Table of Key Differences

Let’s compare the three terms side-by-side:

| Term | Meaning | When to Use It | Example Uses |

|---|---|---|---|

| Wood | General material from trees | Construction, framing, and structural uses | “Wood furniture,” “hardwood vs. softwood” |

| Timber | Unprocessed logs or large, heavy beams | Construction, framing, structural uses | Timber framing, log homes |

| Lumber | Milled boards used in construction | Framing, building, decking, furniture | 2x4s, plywood, fence posts |

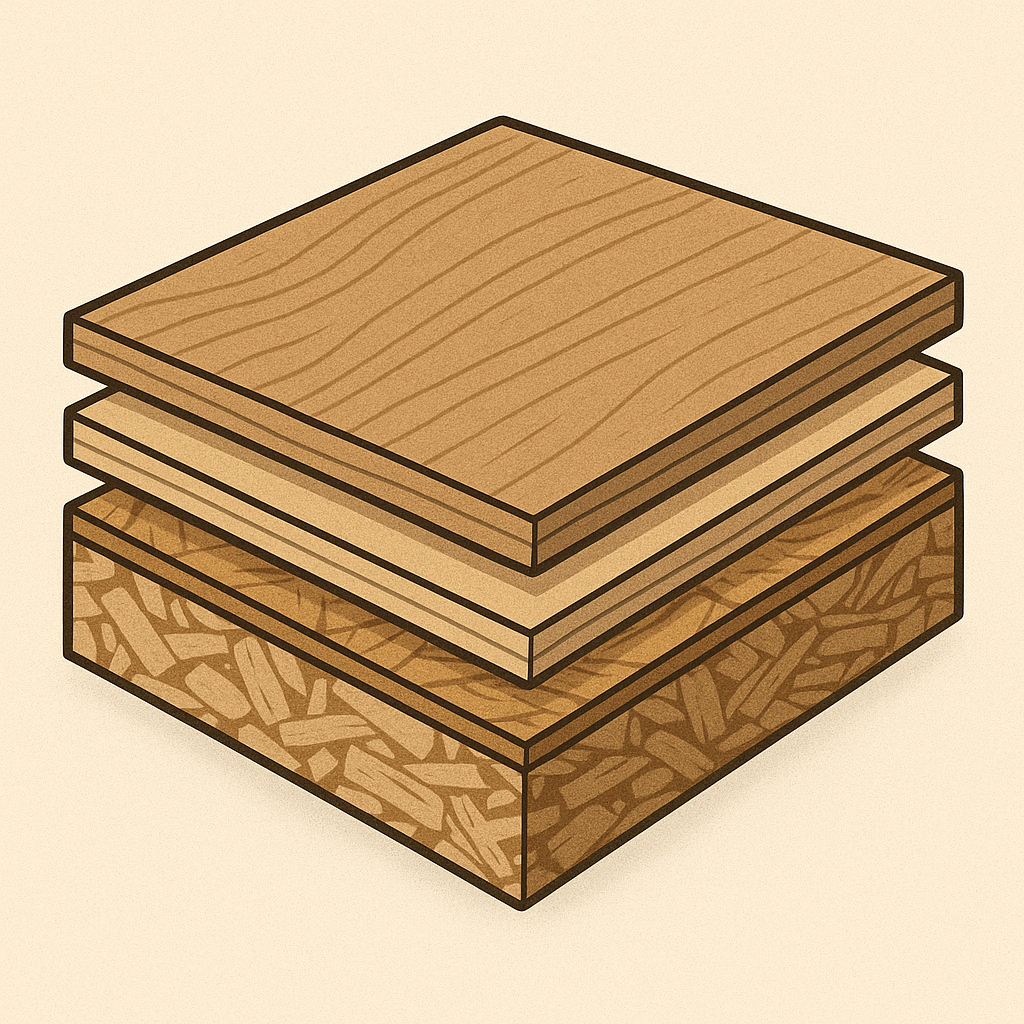

Engineered Wood vs. Solid Wood: What Counts in the Timber Lumber Wood Difference?

While not part of the traditional timber-lumber-wood trio, engineered wood is worth mentioning; products like plywood, MDF, OSB, and LVL beams are made from wood particles or veneers bonded with resin under pressure.

Benefits of Engineered Wood:

- More uniform than natural wood

- Often cheaper

- Uses wood scraps, reducing waste

- Can be stronger and more stable than solid wood

🧰 Affiliate Picks:

🔗 Related Post: Is MDF Safe for Indoor Projects?

Timber and Lumber Around the World: Regional Differences in Wood Terminology

To add to the confusion, these terms vary across countries. In the United Kingdom, for instance, “timber” refers to what Americans call “lumber.” Meanwhile, the word “lumber” is rarely used at all in the UK.

U.S. vs. U.K. Terminology:

| Term | United States | United Kingdom |

|---|---|---|

| Timber | Unmilled logs or large beams | Milled boards (U.S. “lumber”) |

| Lumber | Milled construction wood | Rarely used |

| Wood | Raw material from trees | Same as U.S. usage |

So if you’re reading a British woodworking guide and it says “buy timber,” it probably means buying what Americans call “lumber.”

Choosing Between Timber, Lumber, and Wood for Your Next DIY Project

Still confused? Here’s how to decide which term (and material) you need based on the project you’re doing:

🛠️ Building a Deck?

Use lumber. Pressure-treated dimensional lumber is standard for deck frames and supports.

🛠️ Timber Framing a Shed?

Use timber. You’ll want 6×6 or larger beams for the framing.

🛠️ Crafting Furniture?

Use wood as the general term, but look specifically for hardwood boards or plywood panels, depending on your design.

🪑 Affiliate Picks:

🔗 Related Post: Best Plywood for Cabinet Building

Final Thoughts

Understanding the timber lumber wood difference isn’t just about sounding smart—it helps you make better buying decisions and prevents costly mistakes. Whether you’re sketching a new furniture design, building a shed, or just browsing materials online, knowing the right term helps you find the right product faster.

If you’re ever unsure, remember this:

- Wood is the raw material.

- Timber is raw or large structural pieces.

- Lumber is the milled, ready-to-use building material.

🔎 Pro Tip: Bookmark this page for quick reference next time you’re at the lumber yard!

Bonus: Tools Every Woodworker Should Own

To make the most of your timber, lumber, or wood projects, here are some must-have tools:

🧰 Recommended on Amazon:

Ready to Build?

🔎 Is all lumber made from timber?

Yes—at least in the U.S. definition. Timber is the raw product (a felled tree or log), and lumber is what results when that timber is milled into dimensional boards. So, in a way, lumber is just processed timber. However, not all timber ends up as lumber—some becomes firewood, mulch, or is used for log construction.

🔎 Can hardwood be called lumber?

Absolutely. Hardwood species like oak, maple, and walnut are often referred to as hardwood lumber, especially in the furniture and cabinetry industries. However, in casual conversation, people might simply say “wood” when referring to a hardwood board.

🪑 Affiliate Pick:

👉 Maple Hardwood Boards for Furniture Projects

🔎 Is pressure-treated wood considered lumber or timber?

That depends on its size. Most pressure-treated products sold in hardware stores are dimensional boards (like 2x6s or 4x4s), so they’re classified as lumber. But if you buy a large 6×6 or 8×8 post that retains some bark or is very rough, it might be sold as treated timber.

📌 Tip: Always wear gloves and a dust mask when cutting pressure-treated wood. The chemicals can irritate your skin or lungs.

🧤 Affiliate Pick:

👉 Anti-Cut Work Gloves for Woodworking

🔎 Can you use timber for fine woodworking?

Technically, yes, but it’s not ideal. Timber is usually rough-sawn and oversized, so it requires a lot of milling to make it usable for precision joinery or cabinetry. If you’re building a rustic piece or a timber-framed structure, it’s perfect. But for fine furniture, stick to milled hardwood lumber or plywood.

🪚 Affiliate Tool Suggestion:

👉 Benchtop Planer for Smoothing Rough Timber

🔎 What’s the difference between timber and logs?

Good question. A log is an entire section of a tree trunk, usually with bark still on it. Once a log is designated for building purposes, especially when used structurally or milled into large beams, it’s often referred to as timber. So, in short, a log becomes timber when it’s cut for construction or lumber purposes.

Final Word: Timber, Lumber, or Wood?

Understanding the timber lumber wood difference can help you:

- Buy the right material for your project

- Communicate clearly at the lumberyard

- Make smarter woodworking decisions

- Avoid ordering the wrong products online

Don’t worry if you still catch yourself mixing them up—it’s a learning curve for everyone. But the more you work with these materials, the more natural the terminology becomes.

And hey, even if you call it “that board thingy,” what matters is getting out there and building something.

Bonus Resources for DIYers and Builders

🧰 Want to expand your home woodshop or tackle your next big project? Here are a few helpful tools and kits that pair well with timber, lumber, and woodwork of all kinds:

✅ Kreg Pocket Hole System – Ideal for clean joinery with softwood and hardwood lumber

✅ Timber Framing Square – Must-have for precise layouts on large timbers

✅ Carpenter’s Workbench Kits – Build your DIY bench from dimensional lumber

✅ Dust Collection Hose Set – Keep your woodshop clean and safe

🔗 Related Article: How to Set Up a Woodshop at Home (DIY Guide)