Luan plywood, also known as Lauan plywood or Philippine mahogany, is made from the wood of the Luan tree (Shorea genus). Due to its affordability and versatility, it’s commonly used in construction, furniture making, and other woodworking projects.

Key Characteristics and Uses of Luan Plywood

- Appearance: It is light reddish-brown and has a relatively smooth surface. It may have a slightly coarse texture, depending on the grade and manufacturer.

- Affordability: One of the main advantages is its affordability compared to other types. This makes it a popular choice for budget-conscious projects.

- Versatility: It can be easily cut, shaped, and finished, making it suitable for various applications. Used commonly for interior paneling, furniture backs, cabinet backs, and drawer bottoms.

- Lightweight: Relatively lightweight compared to other types, making it easier to handle and transport.

- Strength: Offers decent strength and stability for many applications. However, it may not be suitable for heavy-duty structural uses.

- Veneer: The surface often features a thin veneer of Luan wood, which provides an attractive appearance and can be stained or painted to match various design schemes.

- Moisture Resistance: It is not particularly resistant to moisture or humidity. It’s best suited for interior applications or areas where it won’t be exposed to prolonged moisture. Luan plywood is lightweight, flexible, and relatively inexpensive compared to other hardwood options.

The first Luan plywood panels were manufactured in the Far East, in the countries of Taiwan, Japan, and Korea, more than forty years ago. The raw wood logs used to manufacture Luan plywood were imported mainly from Indonesia, Malaysia, and the Philippines. Since then, exports of engineered wood products have reached around the globe.

The surface finish is exceptionally smooth and mostly without defects. The few small knotholes found are usually filled and sanded smooth with the surface. They provide an excellent surface for underlayment and furniture building. However, these minor defects relegate Luan to projects. The finished product will be painted and easily concealed, such as the back panel of dressers and other cabinet cases.

Luan Plywood History

Luan became a favored material for plywood because the tree was prevalent throughout the Pacific Rim. The tree grew so that it created logs that tended to be straight, with fine-grained wood consistent with color, size, and density, and the wood fibers were relatively stable. Compared to other trees, peeling the wood in thin layers is extremely easy, a necessity for producing skinny like Luan.

At the same time that the Lauan tree’s wood was discovered to be suitable for, the demand for the hardwood plywood grew globally. This resulted in substantial manufacturing industries in certain parts of the Pacific, including Indonesia, where an estimated 10 million cubic meters was manufactured annually.

However, the industry has declined due to overharvesting and a lack of sustainability management. Today’s Luan is made from the wood of the Lauan tree and a range of different tropical woods. The wood comes not only from the South Pacific Rim. Today, it comes from diverse areas such as South America, Africa, Southeast Asia, and the South Pacific Rim.

Production

To make Luan plywood, thin ‘slices’ of wood, called plies, are laid over each other at right angles until the desired thickness is reached and glued together. The plies are cut from a tree trunk on a large lathe, which peels off a long, continuous layer of wood veneer to the desired thickness.

Once glued under compression, the sheets are stacked and allowed to dry. Individual sheets are then gently sanded to ensure a smooth finish, while any imperfections are filled in and sanded down once again.

Thickness

It is typically only manufactured in thicknesses of a 1/4 inch, although you can find it as thin as 1/8 inch at times. Being so thin, its utility for furniture and construction is somewhat limited. However, it is often used for carcass and bookshelf backs in cabinets and can also be used for side panels in older furniture with inset panel sides. What makes it effective in these applications is the low cost of Luan.

This type of plywood’s delicate nature and smooth surface make it ideal for applications where rigidity is needed in wood panels that are wider than three or four inches. Other places where Luan is commonly used include the construction of wooden dollhouses, crafts projects, and toys. Using Luan plywood for these applications is much easier and cheaper than resawn dimensional hardwood lumber.

Luan is rarely used in remodeling. However, there are some applications where it is beneficial, especially when curved surfaces are needed. Carpenters learned how to use it for columns, curved walls, archways, and reception desks with curved surfaces long before those specialty products existed. While there are plywoods manufactured today that are specially designed for curving, Luan has been around longer than any of them.

The thickness table makes it easier to compare to other types, and the prices chart shows that Luan is available for every budget category.

Cutting Luan Plywood

Cutting Luan can be a bit of a challenge due to it being so thin and flexible. In addition, the face and reverse veneer layers are extremely thin, causing them to splinter quickly. Care must be taken when cutting Luan, especially when crosscutting it.

You want to cut Luan plywood on a table saw with a fine-toothed blade whenever possible. While cutting it with a normal rip blade is possible, you will get less splintering and saw marks if you switch your blade to a crosscut one. It will be necessary to support it, as it is not stiff enough. Table extensions, especially on the left of the blade and the outfeed, are beneficial. If you have someone to assist you with full sheets, it helps make it easier to control the sheet.

For Long Cuts

For long cuts with a circular saw, especially ripping the plywood, you best support the Luan on either side, blocking it up with dimensional lumber. The supports should be on either side of the cut line and the edges of the sheet. This means supporting the sheet of Luan in four places unless you are making a narrow cut.

Crossingcut

When crosscutting, especially with a jigsaw, there is a great tendency to splinter the surface veneers. You can solve this problem by cutting through the surface veneer with a utility knife on the cut line. When cutting with a circular saw, set the saw for a shallow cut to minimize the friction of the blade passing through the sheet. By keeping your saw blade next to this cut and not overlapping it, you avoid splintering the wood on the side you hold.

Taking that idea further, making two cuts through the surface veneer, one at your intended cut line and another 3/16″ into the scrap piece, is good. That way, you won’t be splintering the surface veneer on the scrap, keeping it useful for other projects.

This precutting of the surface veneer is especially important when cutting Luan on a jigsaw for use in dollhouses and craft projects. In these cases, there is typically no edging installed on anything other than the edge of the wood panel. Splintering can ruin the piece one is trying to make. For complex cuts, such as scrolling, precutting the face veneer and ignoring the reverse side veneer is typical, as it is almost impossible to cut both the same. However, in these cases, the reverse sides are typically hidden from view.

Another helpful way of preventing the face veneer from splintering is to cut the Luan with the reverse side up. Splintering occurs when the blade comes back up through the sheet of plywood, ensuring that the upstroke is on the side, exposed, which will remain hidden.

Taping the Surface

Finally, taping the surface of the Luan with masking tape helps hold the surface together, helping to prevent splintering. This is especially useful in cases where you are making curved cuts, such as scrolling, where it may not be possible to cut through the surface veneer very accurately, or where it might be difficult to follow that cut accurately.

Bending Luan Plywood

There are several ways in which Luan plywood can be bent to surround curved surfaces. This is common in the architectural applications mentioned earlier. Commercial offices, especially entryways and reception rooms, may be designed with curved surfaces on reception desks and walls as part of the room’s aesthetics. While other materials can be used to skin over these surfaces, Luan plywood has probably been used more than any other.

Kerfing

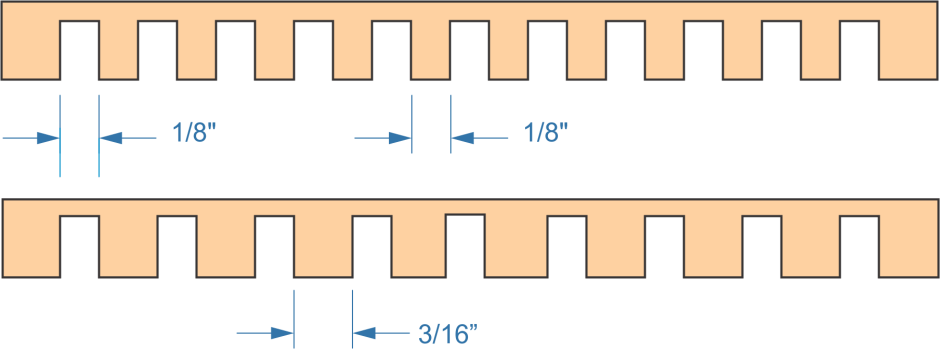

This method takes advantage of the saw kerf made when cutting into the plywood, in this case, with a table saw. Making a series of parallel cuts, most of the way through the plywood, from the back and across the direction of the bend, allows it to be bent, creating a curve.

Since we are limited to the saw kerf, with most circular and table saw blades being 1/8″ thick, we are restricted to how much curvature we can get from one cut. That’s why several parallel cuts are made. Those cuts need to be evenly spaced apart to keep the curvature smooth. The radius of the curve can be adjusted by how close the kerf cuts are to each other. Making a test piece before cutting the final one is always a good idea.

Once the plywood is kerf cut, it can either be bent around the supporting structure and fastened in place. Also, it can be glued and clamped around a mold, leaving it overnight to allow the glue time to set. When waxing the mold or putting waxed paper between the workpiece keep the glue from sticking.

The upper one produces a tighter curve than the lower one

Steaming

This process requires the use of a steam box and a mold. The plywood is placed over the steam box, providing heat and moisture. When sufficiently pliable, the piece is placed around the mold and clamped into place, allowing it to cool and dry for a couple of hours.

Steaming is often used for wood instrument bodies, such as guitar bodies. It is more complex than kerf bending because the process requires a lot of finesse, which only comes from experience.

When steam bending, there will be some spring back of the material from the shape of the mold. While making an overly curved mold is possible, accounting for the spring back isn’t easy. The plywood will readily bend back once it has been bent to a particular curvature.

Soaking

Once sufficiently pliable, the plywood is placed on the mold and clamped into place until dry. This method involves soaking in water for approximately two hours. It is essentially the same as steam bending without needing a steam box. People who do not bend much often use soaking instead of steam bending because it is easier.

Before using either steaming or soaking, it is essential to verify that the glue used in manufacturing the plywood will not be affected by moisture. If it were WBP plywood, this would not be an issue. But to my knowledge, nobody manufactures WBP plywood. Instead, you will need to run your tests on some scraps or stock of your material.

Application

Luan can be used in cabinetmaking, specifically for cabinet sides and backs, where little structural strength is required and a smooth surface is desired. Due to the material being thin and the soft nature of the wood, brads or finishing nails tend to pull out. Attaching it in such cases is best accomplished with staples and glue. Use caution if you choose to fasten Luan with screws, as screw heads can go right through the Luan.

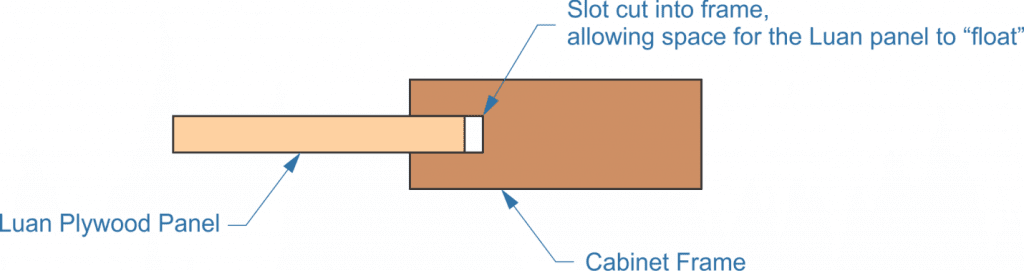

When used for the sides of furniture, such as dressers, the Luan is often set into a slot without fastening. This allows for freedom of expansion due to moisture. This slot also hides the edges of the wood and any possible splintering of the surface veneer.

While Luan is not typically used in new construction, it has some excellent applications in remodeling. When replacing a floor or countertop, the underlayment is often rough, with voids, cracks, glue residue, and unevenness caused by warping. This can be a severe problem when installing hardwood floors, linoleum (roll or tile), and laminate countertops. Installing a layer of ver the existing underlayment provides a smooth surface for installing these finish materials. However, installing Luan under the ceramic tile is not recommended. It doesn’t give a stiff enough surface to prevent grout cracking.

Regarding flooring, Luan makes an excellent underlayment when installed between the subfloor and completed flooring. It provides extra support. Moreover, ensures a smooth, consistent finish to apply the top layer, whether carpet, hardwood floors, or even vinyl tiles.

Red or White Luan

Luan plywood is also often used in the construction of hollow-core doors. When stained, Red Luan resembles mahogany wood, while white Luan may resemble Cherrywood. The result makes a great feature of any home. Of course, Luan plywood hollow-core doors are suitable for indoor use only.

This product, however, is not only suitable for home use. It is equally ideal for different craft projects. Birdhouses, for example, are often constructed of 1/8-inch-thick. This is popular because it does not easily split or splinter during cutting. Also, it is easy to paint over. Moreover, it is used as picture frame backing, supplying the support needed to ensure your pictures do not sag after a while.

Luan plywood is perfect for projects of various sizes. In addition, it’s commonly used in construction, furniture making, cabinetry, and various DIY projects. Since luan plywood may not have the same durability or quality as other hardwood plywood, the usage might be limited.