Radiator covers not only make your room more stylish, but it covers many things as well.

Many old homes were built with steam heat or hot water heating rather than the forced-air heating we use today in homes. Even some newer homes are built with hot water heating, as it is highly efficient.

However, one problem with most homes using steam heat or hot water heat is the unsightliness of the radiators, which rarely fit into a room’s décor.

The obvious answer to that design problem is to find or design some way of covering up the radiator while still allowing it enough space to do its job. This design move is much easier than it might seem if we pay attention to the convection rules.

We should all remember from science class that heat rises and cold drops. This is probably the most critical affecting convection heating work.

If we want something hard to get heated, such as heating air, we should allow space for the cold air to enter from the bottom and room for the warm air to exit at the top. If we do that, we will get natural air movement without adding a fan or anything else to move the air.

So, when designing radiator covers, we must provide natural means for the air to move in that pattern. That means having an air inlet down at the floor of the radiator covers and an air outlet higher up.

Putting that air outlet at the top of the radiator covers still provides maximum possible heating. However, it will still work if the majority of the radiator cover is open to give enough to allow air to flow out.

Types of Radiator Covers

Radiator covers are generally not broken down into types of products or brands of products that have names assigned to them, but they aren’t all the same. We find a few basic differences in how they are made and their style.

The first significant difference to consider is whether the radiator cover is used to provide you with steam heat or hot water heat. Steam heating systems use the old-fashioned cast-iron radiators you probably see in homes throughout your imagination.

These stand roughly 24″ tall and approximately 10″ from the wall. They can be any length, with longer ones installed in larger rooms. Modern steam radiators are made of stamped sheet metal rather than cast iron, but the basic style is the same.

Hot water radiators are much smaller and often called “baseboard heaters.” They are essentially copper pipes with radiator fins attached to them. As such, they don’t need to stand as tall as steam heat radiators, so they are usually only about 10″ tall and stick out from the wall about 4″.

Like steam radiators, they can be long or short, depending on the room size. Still, they are generally longer than steam heat radiators.

The other significant difference we encounter between brands in radiator covers is a styling difference. More traditionally styled radiator covers are made with decorative perforated panels for a view of the warm air outlet. These covers come in various sizes, are usually made of aluminum, and can be painted to match the room’s décor.

Modern-style radiator covers don’t use perforated aluminum panels. Still, the radiator covers use a series of wood strips, which can be mounted horizontally or vertically, but are usually mounted horizontally to better break up the shape of the other radiator covers hidden behind.

When designing and making radiator covers for your home, you want to consider your home’s overall style, including existing woodwork and furniture. Ideally, the radiator cover should make the radiator somewhat invisible, blending it into the style of your home.

Some do-it-yourselfers add storage or seating, making their radiator covers combine into the room better. The exact primary type of radiator cover we will discuss can be used for steam or hot water radiators. The only real difference is that you must adjust the size to match your needs.

Making Traditional Steam Radiator Covers

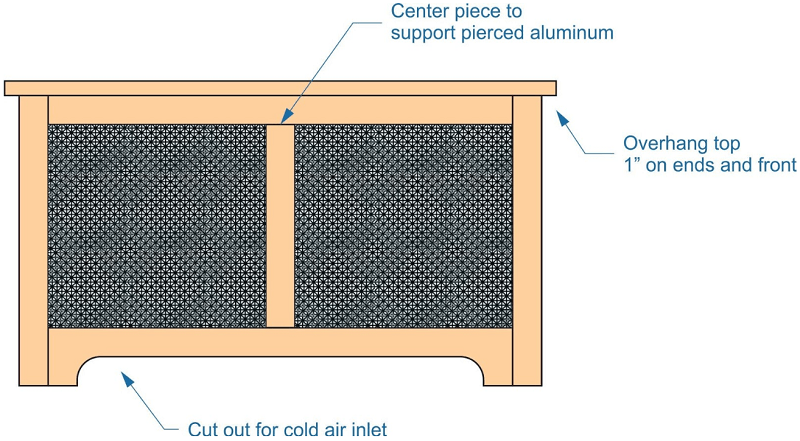

Any radiator cover is essentially four sides of a box: the front, both ends and the top. A bottom is unnecessary, as the floor acts as the bottom, and the back is unnecessary because it is against the wall.

The front of this box is the open part, providing a means for the air to circulate in and out. While some designs also have available parts on the sides, this is unnecessary. A lot depends on the style you are trying to achieve and how much material you want to use to create it.

To make a traditional-style radiator cover, start by measuring your radiator. Your dimensions must be from the wall and the floor, as that matters.

You also want to be sure that you are measuring the radiator at the point farthest from the wall or floor, which may mean measuring at a steam pressure relief valve mounted on the radiator, measuring where the pipe goes into the wall, or measuring at the base of the radiator (some have feet which stick out farther than the rest of the radiator).

At a minimum, you will want to change the inside dimensions of your radiator to be one inch higher, broader, and deeper than the maximum dimensions of your radiator.

While radiators don’t get hot enough to cause the wood to damage, they can cause damage to it over time if they are in direct contact.

Side note: You always want to use well-seasoned wood with a low moisture content when making radiator covers. Due to the heat they generate, improperly cured or damp wood for radiator covers is likely to warp as it dries.

Assembling the Front

The front of the radiator cover should be made of 1″ x 3″ or 1″ x 4″ knot-free boards, while the sides and top can be made of sanded plywood, cabinet-grade plywood, or MDF (medium-density fiberboard). There is no real reason to make the radiator cover out of higher-grade wood unless you plan on staining and varnishing it.

Notice in the layout below how the front panel is laid out in such a way as to prevent the covers from having any end grains exposed. This helps the builders keep the appearance of the entire surface consistent and is typical for the design of builders of six-panel doors. It is somewhat the same sort of design we see builders using here.

Attaching a frame of the type used for the front of this cover together can be difficult, as the pieces are wider than you can reasonably nail together. If you use 1″ x 3″ pieces for the front frame, you can use 3 ½” finish nails or screws through the sides to attach it.

But it would be easier to connect the pieces with a biscuit joiner (if you have one) or dowel pins. Another option is to drill pocket holes and use screws for putting corners together.

Radiator cover front

Once the frame is connected, the perforated aluminum is attached to cover the inside. This can be attached with nothing more than a staple gun and ½” staples. However, to make it a bit stronger, you may want to use ½” long pan head sheet metal screws (yes, I know I’m recommending sheet metal screws for wood, but it works).

Assembling the Top and Sides

Suppose you want to avoid any visible hardware. In that case, the entire project can be assembled by drilling angled pocket holes inside the cabinet and attaching the pieces with screws.

The ends of the cabinet are nothing more than pieces of plywood cut to the dimensions you calculated earlier. You have a choice to make here. Either to allow the cover to sit in front of the baseboard or to cut a relief in the lower back corner of these pieces to fit around the baseboard. I prefer This second option; otherwise, you’ll beat up the baseboard where the side pieces meet it.

Radiator cover side

The last piece to attach is the top. With the front overlapping the sides, the only end grain that will be visible will be for the top piece. There are three options to consider here:

- ⦁ Make the top out of MDF, where there shouldn’t be any end grain. The little bit of grain showing along the edge is quickly filled and sanded.

- ⦁ Make the top of plywood, where the end grain is offered on the front and sides. In this case, I’d recommend covering the edges with a veneer edging. This usually comes with hot melt glue on one side, allowing you to heat bond it to the edge of the plywood.

- ⦁ Made out of solid wood, only the end grain is showing at the ends of the cover. This would probably be acceptable, especially if you did decorative routing on the edge.

If you are not cutting relief notches in the two end pieces, you can assemble the radiator top to the cover before putting it in place. However, if you are not cutting relief notches, it is best to set the radiator cover in place and then attach the top to the front and sides of the radiator cover.

Making Modern Radiator Covers

Making a modern-style radiator cover is much like making the traditional ones, except for the perforated aluminum. The trick here is coming up with the wood strips you will use instead of the perforated aluminum. One option is to buy lathing strips if you can find them.

If you can’t find them, you can rip a 2″ x 4″ into ¼” thick strips on your table saw. This helps keep the overall cabinet thickness down, rather than using ¾” thick material.

When ripping 2″ x 4″ studs for a project like this, you want to find the most knot-free lumber you can. Even so, plan on having a fair amount of scrap, as you probably won’t want to use the pieces with knotholes. If you have trouble finding it, you can probably find 2″ x 2″ pieces that are select grade and will be knothole free.

As mentioned, there are two ways of doing this; mounting the wood strips horizontally or vertically. The methodology for the two is different.

For Horizontal Strips

Instead of installing the aluminum, make the cabinet just like before. Then mount strips of wood horizontally to cover the front on the outside of the framework.

The trick here is going to be to get your spacing perfect. I don’t recommend using a spacer between the strips to space them out, as that can cause problems if there is any inconsistency. Instead, mark the spacing on the ends of the frame so that you can be sure to keep their order consistent.

For Vertical Strips

Vertical strips can be installed the same way as horizontal ones, but it is better to cut a ¼” deep rabbet on the inside of the top and bottom rails of the frame and attach the strips. This design provides a cleaner look and hides the strips’ end grain rather than exposing it.

Finishing

Most people paint their radiator covers, although it is possible to stain and varnish them. One thing that works out exceptionally well with any of the styles mentioned above is to paint the top, sides, and front framework of the door panels one color and the pierced aluminum or wood strips that make up the grating in the door panels another.

In such a case, the casing door panels could match your room’s trim, with the grind matching the walls or accent color you use.

The space on top of the radiator cover makes a handy shelf for various home decorative purposes. If you place a plant here, be sure to change the water frequently, as the heat from the radiator will make the water evaporate faster than it does for other plants in your home.

Another top protection option for low radiators, such as the type under a window, is to make a custom cushion to place on top to cover the radiator cover, turning it into a window seat.

The cushion will provide some protection and offer sufficient insulation so that it won’t seem like you are sitting on a hot seat.