Forming corners in plywood when building cabinets or casework is not always as easy as it might seem. Plywood has many advantages and strengths but also some important weaknesses and forming corners and edges in any kind of cabinet or casework is where these strengths and weaknesses surface. There will be occasions when edges and corners will be visible and exposed. It may not be desirable to leave the inner laminates of the sheet material exposed to view.

Also, exposed plywood edges and corners will be susceptible to impact and abrasion. Exposed plywood edges represent the point of greatest weakness in plywood products; always give special attention to this when designing a piece that will result in exposed edges.

Miter joints

Miter joints with plywood sheets will hide the inner plies from view but is not usually a very satisfactory solution. First of all because nailing, screwing or gluing the edges together will be difficult unless back blocking is used. Secondly, unless the miters are extremely well cut and the final piece is exactly square, there will be a tendency for the miter to ‘gape’ or pinch, meaning that the gluing will be not as strong as it should be and the joint will be subject to failure.

Also, the exposed outer laminates of the plywood, which are usually the thinnest, will be susceptible to snagging and spitting on impact or abrasion. This is why most cabinet shops will avoid using plywood to form outer corner connections and use solid, non-laminate material in these locations. This is why in standard ‘face frame’ cabinets, the face frame itself will be fabricated from solid wood stock.

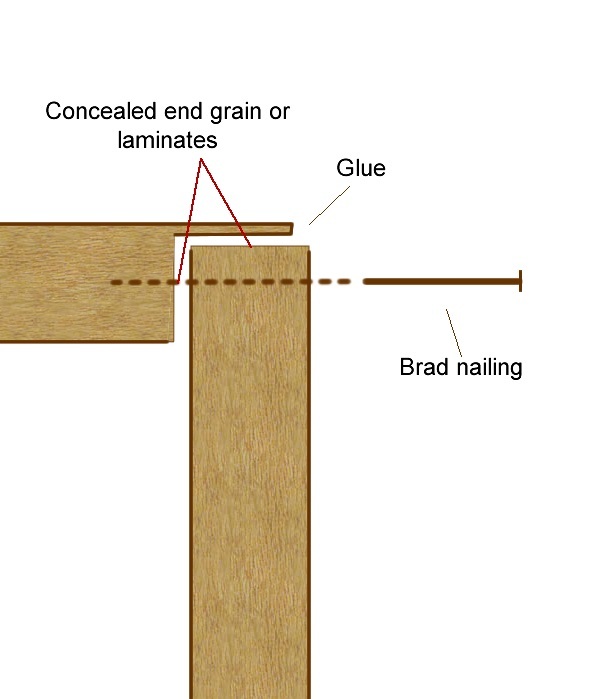

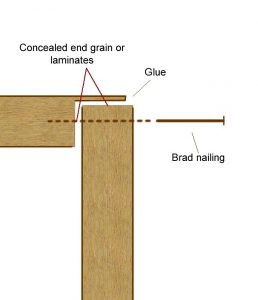

However, there are work around – one is not to use a mitered connection, but something closer to a butt joint, which is stronger. This joint, which is made by first cutting a deep rabbit along one of the edges to be connected, has the strength of a butt joint but allows for more effective gluing and, at the same time, conceals almost all of the inner plies of the laminated material. The result in a much more durable, and ultimately attractive connection.