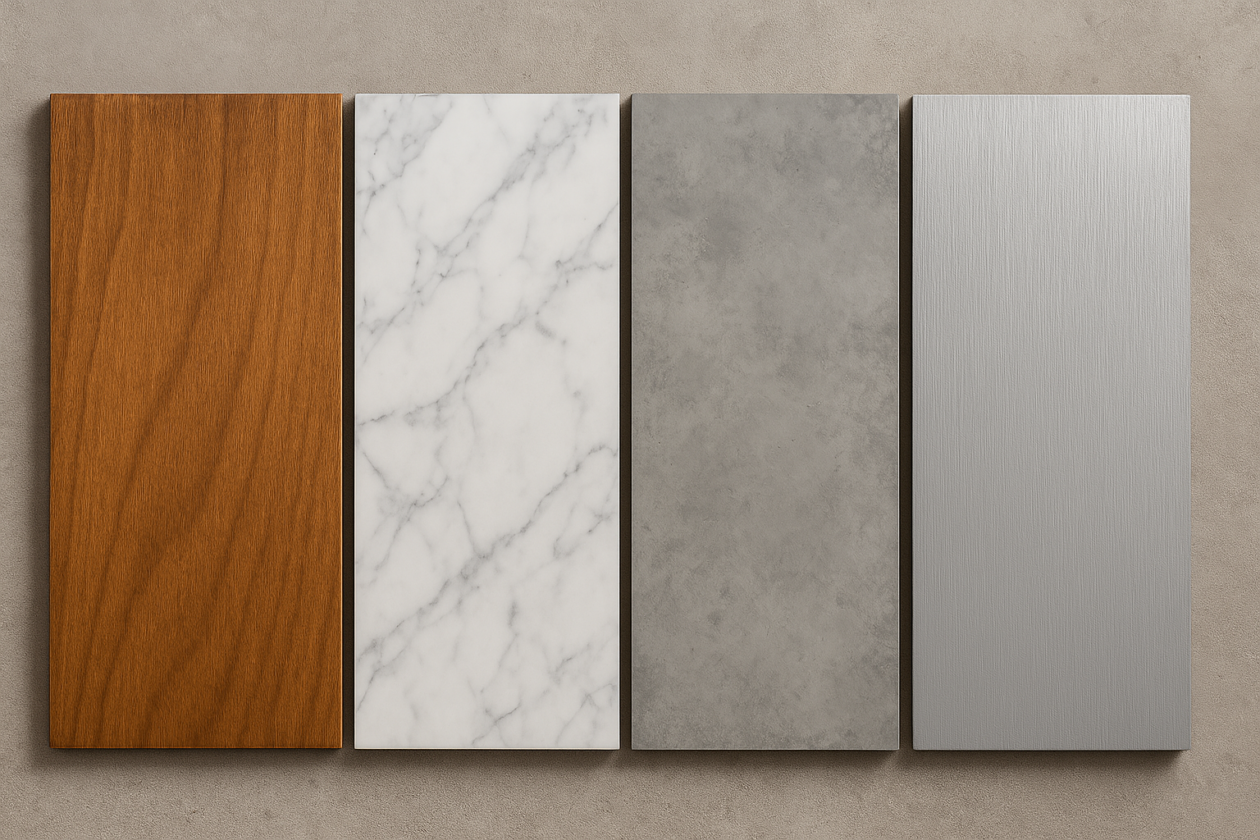

Most people think of plywood as just cheap, utility-grade wood. For years, I thought the same—until I started working on weekend furniture builds in my garage and realized how much potential it actually has. I’ve used plywood to create pieces that look like solid oak, brushed metal, even marble. Some attempts were a disaster (don’t ask about my first faux concrete shelf), but others turned out so well that I’ve used them in multiple projects since.

Whether you’re trying to save money or just love getting creative, here are six DIY finishes that have helped me make plywood look surprisingly high-end.

1. Turn It Into Faux Hardwood (Without the Price Tag)

If you’re working with a nice plywood veneer—like birch or maple—you already have a decent surface. I used birch when building a bench for our entryway because real oak was out of budget. The trick is in the prep and the stain.

Here’s what worked for me:

- Sand thoroughly. I start with 150 grit and finish with 220. This part takes time, but uneven sanding will ruin the finish.

- Use a wood conditioner. I used to skip this, but after one blotchy disaster, I never forget it now—especially on soft woods.

- Apply a gel stain. Gel stains are thicker and easier to control. I like walnut for a classic hardwood look. I brush it on, then wipe it with an old t-shirt.

- Finish with polyurethane. I usually do two coats of satin poly. It gives a smooth, professional-looking finish without the high gloss that shows every speck of dust.

Bonus Tip: Try a wood grain tool while the stain is still wet. I bought a cheap one online and was blown away by the effect.

2. Faux Brushed Steel (Perfect for Modern Projects)

This finish started as an experiment with leftover spray paint—and it turned out better than expected. I used it on floating shelves in my office, and most people think they’re metal.

How I pulled it off:

- Prime with gray. It gives a smooth, even base and helps the metallic layer pop.

- Roll on metallic silver paint. A foam roller gives a smoother finish than a brush.

- Add texture with a dry brush. While the paint is still tacky, I drag a stiff-bristle brush in long strokes to mimic brushed steel.

- Glaze it. I wipe on a little black glaze and quickly rub it off. It settles into the texture and adds depth.

This finish looks great with black hardware and fits perfectly in modern or industrial-style rooms.

3. DIY Marble Finish (That Doesn’t Cost a Fortune)

Marble looks great, but it’s pricey and heavy. I wanted that same clean, high-end look for a coffee table and finally figured out two ways to fake it: epoxy or paint.

Epoxy Method:

- Paint the base white. A smooth base coat makes a huge difference.

- Mix epoxy with pigment. I use Stone Coat epoxy and blend in black and gray pigments.

- Swirl and blend. Pour the epoxy and swirl the colors using a stir stick or gloved hands. It’s messy but fun.

- Use a heat gun. A quick pass pops the bubbles. Then, hands off—let it cure for 48 hours.

Painted Version:

- White satin paint for the base.

- Add veins with a feather or fine brush. Diluted gray paint works best. Don’t overthink the lines—real marble isn’t perfect.

- Soften the look. I dab the lines with a damp sponge until they blend naturally.

- Topcoat with gloss. A clear, glossy polycrylic makes the surface pop.

My faux marble coffee table has fooled more than one guest. And the best part? It cost under $40.

4. Concrete Style Without the Weight

I love the clean, minimalist vibe of concrete, but real concrete is heavy and a pain to work with. This plywood trick gives a similar look with much less hassle.

Here’s my shortcut:

- Prime the surface. I use a bonding primer to help everything stick.

- Mix gray chalk paint with baking soda. It gives the paint texture and helps it cling.

- Layer in different gray tones. I dab on light and dark grays with a sponge until it looks imperfect (on purpose).

- Optional: Add a skim coat. Apply a thin layer of joint compound for extra texture, then lightly sand once dry.

- Seal it with matte poly. It tones down the shine and makes it look more like real cement.

I used this finish on a plywood desktop, and it’s held up surprisingly well, even with daily use.

5. Weathered & Rustic Finish (Barnwood Vibes)

If you want your plywood to look like it’s been through 50 years of wear and tear, this one’s a blast to do. It’s messy, hands-on, and worth it.

Here’s how I distress plywood:

- Beat it up. I use chains, hammers, and screws to add random dents and scratches.

- Drag it with a wire brush. Go with the grain for a natural, worn look.

- Apply a wash. I use watered-down white or gray paint, brush it on, then wipe it back off.

- Sand the edges. Focus on corners and random spots to add to the aged effect.

- Seal it with a matte finish. I use either wax or a flat poly, depending on the project.

This works excellent for farmhouse-style furniture, wall art, or rustic shelves. It gives plywood a ton of character for minimal cost.

6. Burnt Finish (Inspired by Shou Sugi Ban)

This one is dramatic and absolutely eye-catching. I tried it first on a planter box and was hooked.

Here’s how I do it safely:

- Use a propane torch. Hold it a few inches above the surface and move slowly. Too close and you risk burning through the top layer.

- Scrub with a wire brush. Once it cools, brushing removes the soot and brings out the grain beautifully.

- Apply tung oil or linseed oil. It deepens the color and protects the surface.

It smells like a campfire for a day or two, but the finished look is bold and beautiful—perfect for accent panels or outdoor projects.

My Favorite Tools & Products

(These are affiliate links—I only recommend what I actually use.)

- Minwax Gel Stain – Easier to control than liquid stains, great for hardwood looks

- Rust-Oleum Metallic Paint – Best silver finish I’ve found for faux steel

- Stone Coat Epoxy Kit – A must if you’re going for faux marble

- Polycrylic Clear Coat – My go-to sealer for almost everything

- Feather Brushes – Makes faux marble veins a lot easier

Final Thoughts

If you’ve ever looked at a sheet of plywood and thought, “This is too plain to be useful,” think again. You don’t need a shop with fancy tools or a massive budget to make plywood look amazing. A little creativity, some patience, and the right finish can turn a humble board into something that looks high-end and custom.

The key is to experiment. Don’t be afraid to mess up—that’s half the fun. Start with a scrap piece, try one of these finishes, and see what works for your style. You’ll be surprised how far a sheet of plywood can go when you know how to make it look nice.