Here’s the deal — not all plywood is created equal. If you’ve ever grabbed a few sheets for a weekend project, only to find out they warped or sagged a month later, you probably picked the wrong kind.

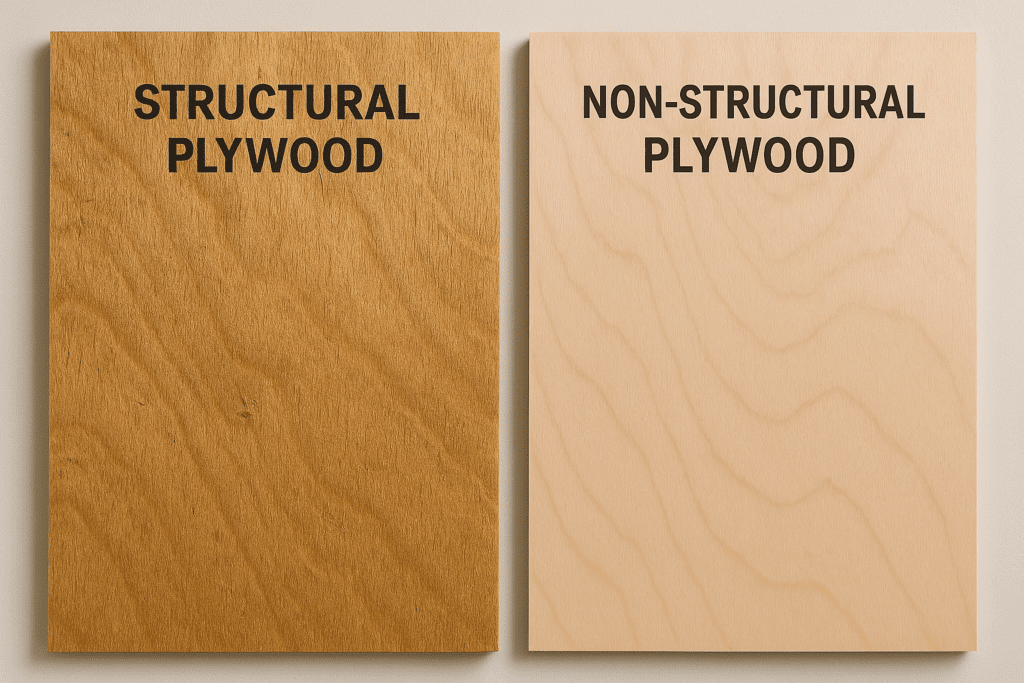

There are two main types: structural and non-structural plywood. One’s made to hold up a house. The other’s made to look good inside one. Picking the wrong one won’t just mess up your project — it might cost you extra time, money, or even require a full do-over.

So, What Exactly Is Structural Plywood?

Structural plywood is the workhorse. It’s built to handle stress — literally.

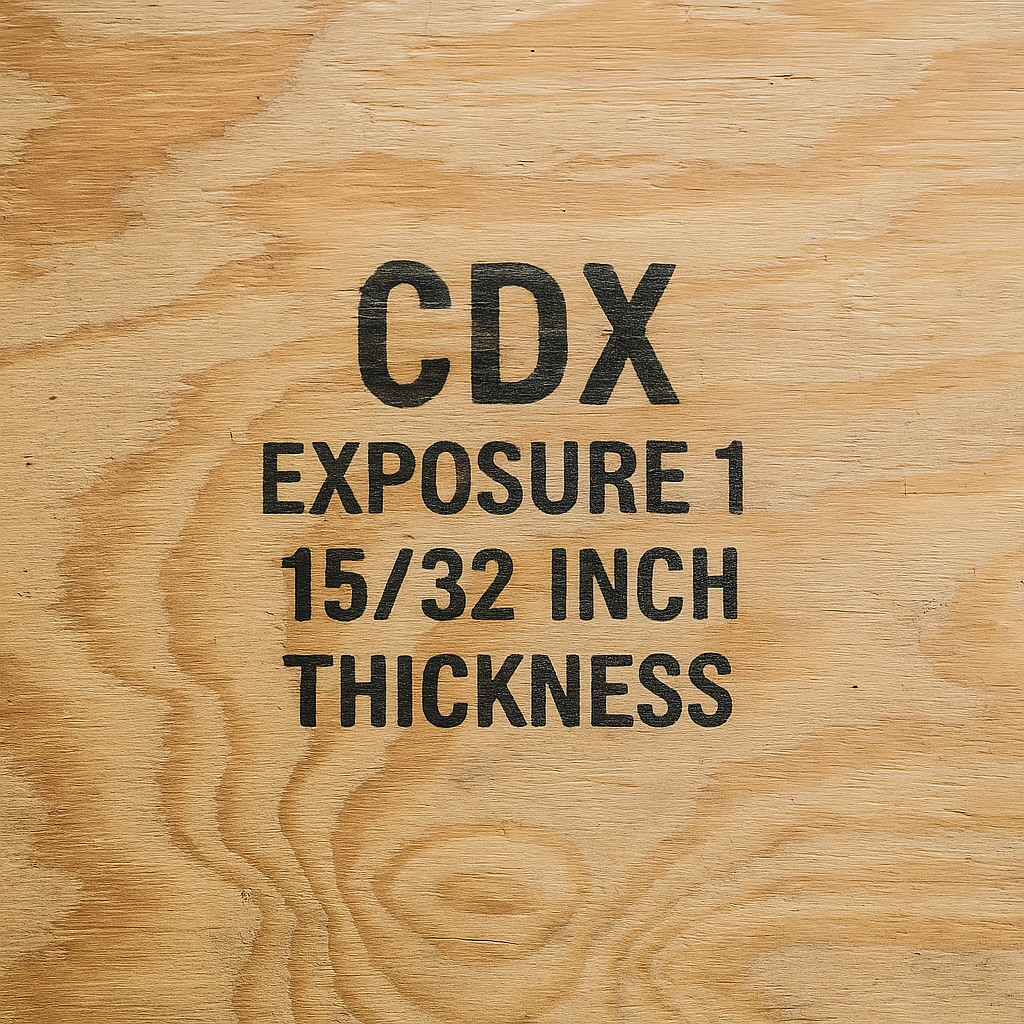

You’ll usually see it labeled as CDX, OSB, or with a stamp like “Structural 1” or “Exposure 1.” Those stamps mean the sheet meets standards for load-bearing applications and moisture resistance. It’s used in framing, sheathing, roofing, and other parts of a home where strength really matters.

Real Projects I’ve Used It For:

- A shed floor: This was built to sit on concrete blocks, and the plywood needed to hold weight without bending. Three years later, still no sagging.

- Subfloor patch in the laundry room: After a slow leak warped the original flooring, I replaced part of the subfloor with structural plywood. Holds the washer and dryer no problem.

- Garage wall sheathing: Used as a backer to hang heavy-duty shelving for tools and paint cans.

If you’re framing, walking on it, or building outdoors, structural is the way to go.

Non-Structural Plywood: Clean Looks, But Keep It Dry

On the flip side, non-structural plywood is meant for projects where appearance matters more than muscle. It’s lighter, smoother, and easier to finish or paint. But it can’t hold much weight, and it doesn’t like moisture at all.

It’s usually labeled as interior-grade or decorative-grade plywood. Think birch veneer, oak, maple — those slick-looking panels you’d want to display, not hide behind drywall.

Where I’ve Used It:

- Built-in bookshelf: I needed clean lines and a smooth surface for painting.

- Closet shelves: Light duty, but looked sharp with a dark walnut stain.

- A fake ceiling beam: Non-structural panels wrapped around a box frame — no weight, just looks.

That said, I once used it to patch a kitchen floor and learned that it buckles fast when exposed to even mild humidity.

Cheat Sheet: What to Use and When

| Feature | Structural Plywood | Non-Structural Plywood |

|---|---|---|

| Load Bearing | Yes — designed to support weight | No — for aesthetics only |

| Water Resistance | Moderate to high, depending on rating | Very low — for dry, indoor use only |

| Finish Quality | Rough, utility-grade | Smooth, great for staining/painting |

| Common Projects | Framing, subfloors, roofing, sheds | Cabinets, shelves, paneling, furniture |

| Cost | Typically cheaper per square foot | More expensive for premium veneers |

Understanding the Labels

If you’re not sure which type you’re holding, flip the plywood over and check for a stamp. Here’s what some of the labels mean:

- CDX: Structural-grade plywood with one rough face (C) and one smoother face (D). The “X” is rated for exterior use (but not full waterproofing).

- Exposure 1: Suitable for limited moisture (like during construction).

- Structural 1: Built to hold up in seismic or high-wind areas.

- Interior Grade: Not for wet or weight-bearing use — suitable for furniture and decor.

If there’s no stamp at all, or the panel feels super lightweight and smooth, it’s probably non-structural.

Specialty Plywoods Worth Knowing

🔹 Marine-Grade Plywood

This stuff is a whole other level. It’s designed for constant moisture exposure — like boats, docks, or planters that sit outside year-round. I built a set of herb boxes for the patio using marine-grade plywood. Three summers later, they still haven’t rotted or split.

Marine-grade panels use waterproof glue, no interior voids, and are made from durable hardwoods.

🔹 Formply (aka FormPly or Film-Faced Plywood)

Made initially for reusable concrete molds, Formply has a dark, slick surface that resists water and concrete residue. Surprisingly, it’s also become popular in the modern DIY space for furniture builds — especially workbenches and industrial-looking shelves. I used some offcuts for a tool bench top and it’s held up better than anything else I’ve tried.

Common Mistakes to Avoid

- Using non-structural plywood outdoors: It might look great in your patio chair build, but rain will ruin it fast.

- Confusing smooth surface with quality: Just because it looks nice doesn’t mean it’s strong.

- Skipping the label check: Always read the stamp — don’t guess.

Quick FAQs

Can you paint or stain structural plywood?

Yes, but it won’t look perfect. Structural plywood is usually rougher and may have knots, gaps, or patching. It’s best used where appearance doesn’t matter — or hidden behind drywall.

Is marine plywood overkill?

Only if you’re using it indoors, for anything exposed to weather or high humidity (like under a sink or near a washer), it’s absolutely worth it.

What’s the best plywood for cabinets?

Non-structural hardwood plywood: Look for birch or maple with a smooth veneer and consistent grain. Interior-grade glue is fine as long as it stays dry.

Final Word

Structural plywood is your go-to if your project needs to hold weight or face the elements. If it’s purely decorative or meant for a dry, indoor space, non-structural will save you some money and give you a better finish.

Plywood can feel confusing at first, but once you’ve worked with a few types, the differences really stand out. And if you’re ever in doubt? Ask someone in the lumber aisle. Most of them are happy to talk plywood all day.

🛠 Amazon Picks for Plywood Projects

Let’s give your readers trusted, high-quality product options. These are handpicked based on real-world use and strong reviews:

🔨 For Structural Projects:

- GP CDX Plywood 15/32 in. 4×8 (local pickup via Home Depot)

A go-to choice for sheathing, subfloors, and sheds. - Gorilla Heavy-Duty Construction Adhesive

Great for securing plywood to framing — holds strong even in damp conditions. - SPAX Structural Screws

Self-tapping, high-torque — ideal for anchoring plywood to joists or studs.

🪚 For Non-Structural (Indoor) Projects:

- Baltic Birch Plywood Sheets (1/2″, pack of 3)

Pre-cut panels perfect for shelves, drawers, or cabinet faces. - Minwax Polycrylic Water-Based Finish

Great for sealing plywood projects indoors without yellowing. - Kreg Pocket Hole Jig 320

Makes clean joinery on non-structural builds like bookshelves or boxes.

🌧 For Marine or Outdoor Builds:

- Hydrotek Marine-Grade Plywood (local lumberyard or online)

True marine plywood — no voids, great for boats or planters. - TotalBoat Marine Wood Sealer

Penetrates and protects wood from long-term moisture exposure.