A reliable OSB sealer prevents moisture from compromising your OSB panels. Our guide provides straightforward information on selecting the ideal sealer and expert application tips to help arm your OSB against humidity.

Key Takeaways

- OSB (Oriented Strand Board) is a cost-effective, versatile, and environmentally friendly alternative to plywood. It is commonly used in construction for sheathing, subflooring, and more.

- Choosing the right OSB sealer is critical. Oil-based sealers penetrate deeper but take longer to dry, while water-based sealers dry quickly and are more environmentally friendly, but they may not provide a deep seal.

- Proper sealer application to OSB involves cleaning the board, sanding, and applying it with attention to edges and joints. Multiple coats may be required to ensure full moisture protection.

Understanding OSB: Materials and Uses

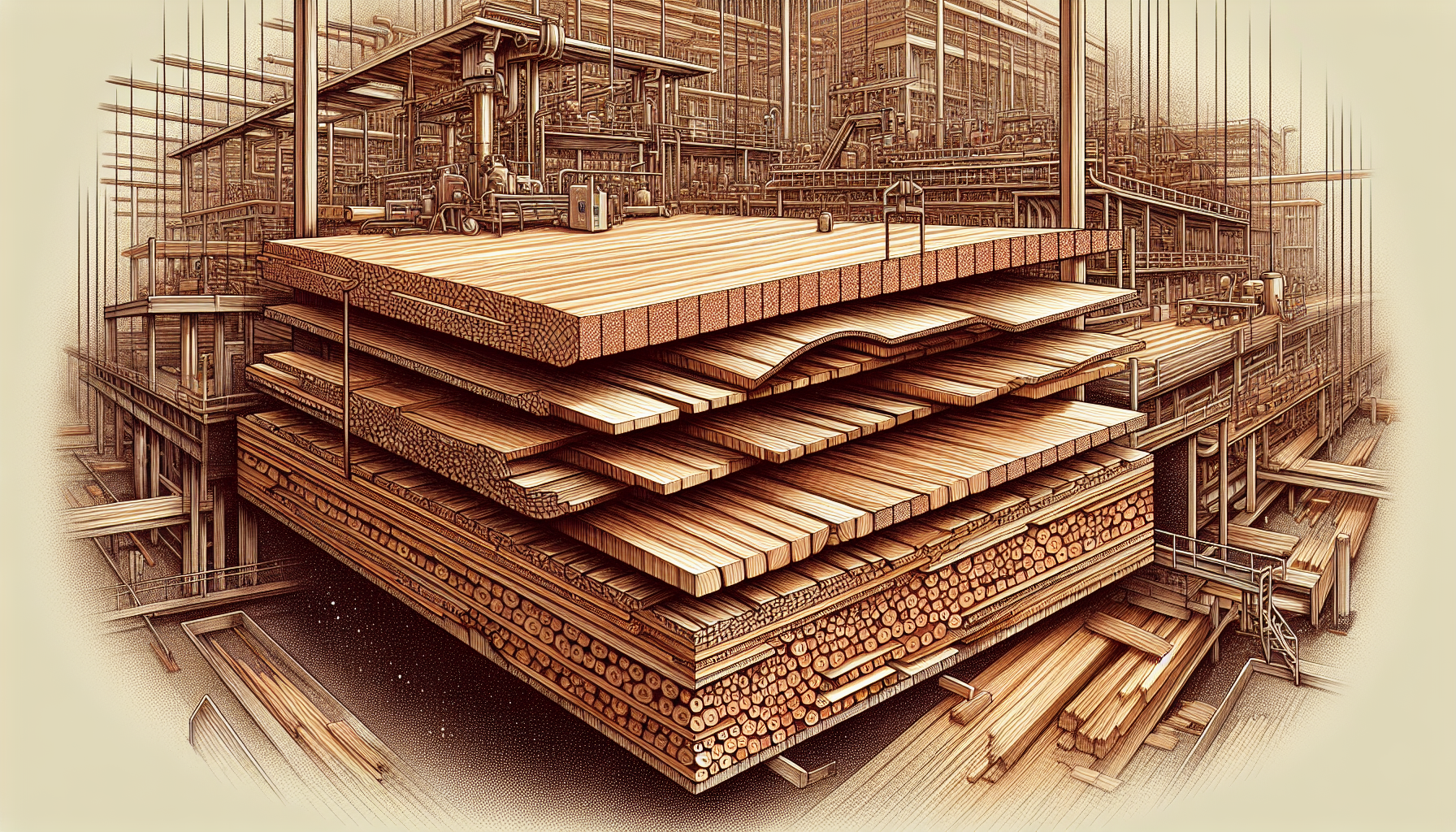

OSB, short for Oriented Strand Board, is an engineered wood product used in construction. Created by compressing and bonding wood strands in specific orientations, OSB is a robust and durable material that offers a cost-effective alternative to traditional plywood. The construction of OSB involves layering wood strands in cross-directional patterns to enhance its mechanical properties and ensure dimensional consistency. The material is bonded using waterproof phenol-formaldehyde resin binders under high temperature and pressure, creating a cohesive, durable panel.

OSB’s thickness can range from 6mm to 25mm to meet various structural and load-bearing requirements in construction projects. Builders and engineers prefer OSB due to its uniform strength and resistance to warping, making it advantageous for various construction applications. OSB’s versatility is showcased through its common applications, such as sheathing, subflooring, roofing, walls, and ceilings.

Plus, it’s considered an environmentally friendly material made from fast-growing, sustainable wood species, and the production process results in less waste than other wood panel products.

Choosing the Right OSB Sealer: Oil vs. Water-Based Products

Sealing is an integral part of maintaining the integrity of the OSB boards. It helps to protect the boards from moisture damage, which can lead to swelling and material degradation. But, when choosing the right sealer for your OSB boards, it’s essential to understand the differences between oil-based and water-based products. These two types of sealers have unique properties and uses, and your choice will depend on several factors, such as moisture resistance, drying time, and environmental impact.

Oil-based sealers, for instance, penetrate deeper into the OSB, providing a better seal but with a longer drying time. On the other hand, water-based sealers:

- dry faster but may not penetrate as deeply into the material

- emit fewer odors and volatile organic compounds (VOCs)

- are considered more environmentally friendly

Keep these factors in mind when choosing a sealer for your OSB.

Oil Based Primer

Oil-based primers are preferred for new OSB surfaces due to their efficacy in covering the black ink markings often present on the panels. They are recommended over water-based options to prevent potential issues with the water-based glue within the OSB reacting negatively. However, oil-based primers may necessitate multiple applications for adequate coverage on OSB and can be labor-intensive, sometimes requiring sanding when applied over glossy surfaces.

While oil-based primers emit a strong odor, the smell is generally sealed once the primer is top-coated with paint. So, an oil-based primer can be a worthy option if you plan to paint over the OSB.

Water Based Products

Switching gears to water-based products, some users have successfully used them on OSB without issues such as surface blistering or chipping. Water-based products are easier to clean than oil-based primers and feature less odor. One of the valued characteristics of water-based products for OSB boards is their quick drying times, allowing for easy soap-and-water cleanup.

However, you need to be cautious when using water-based primers on OSB surfaces affected by heavy grease, water stains, smoke, or fire damage, as they may not be as effective. But if you’re dealing with a relatively clean and dry OSB surface, a water-based product might be the way to go.

Proper Application Techniques for OSB Sealers

Now that we’ve covered the types of sealers, let’s dive into the proper application techniques. Before sealing, clean the OSB board with a broom or vacuum to remove dust, debris, or loose particles for better adhesive bonding. Also, check for and fill any cracks or gaps in the OSB board with wood filler or caulk and allow it to dry thoroughly to prevent water ingress.

Next, here are the steps to prepare and apply the sealer to the OSB surface:

- Lightly sand the OSB surface with sandpaper, going with the grain, to prepare a smooth base.

- Follow the manufacturer’s instructions for applying waterproofing products, ensuring even coverage, especially on edges, joints, and vulnerable areas.

- Use a paintbrush to coat all sides and edges of the OSB board, including cuts, with a waterproof sealer. After the first coat dries, apply a second coat for added protection.

Finally, the seams between adjoining OSB panels must be sealed meticulously to prevent swelling, using products like spray urethane. Allow the waterproofing product to dry and cure according to the manufacturer’s guidelines to ensure maximum water resistance. If necessary, apply additional coats of the waterproofing sealer, following the same procedure as the first to ensure thorough coverage and protection.

Protecting OSB from Weather Elements

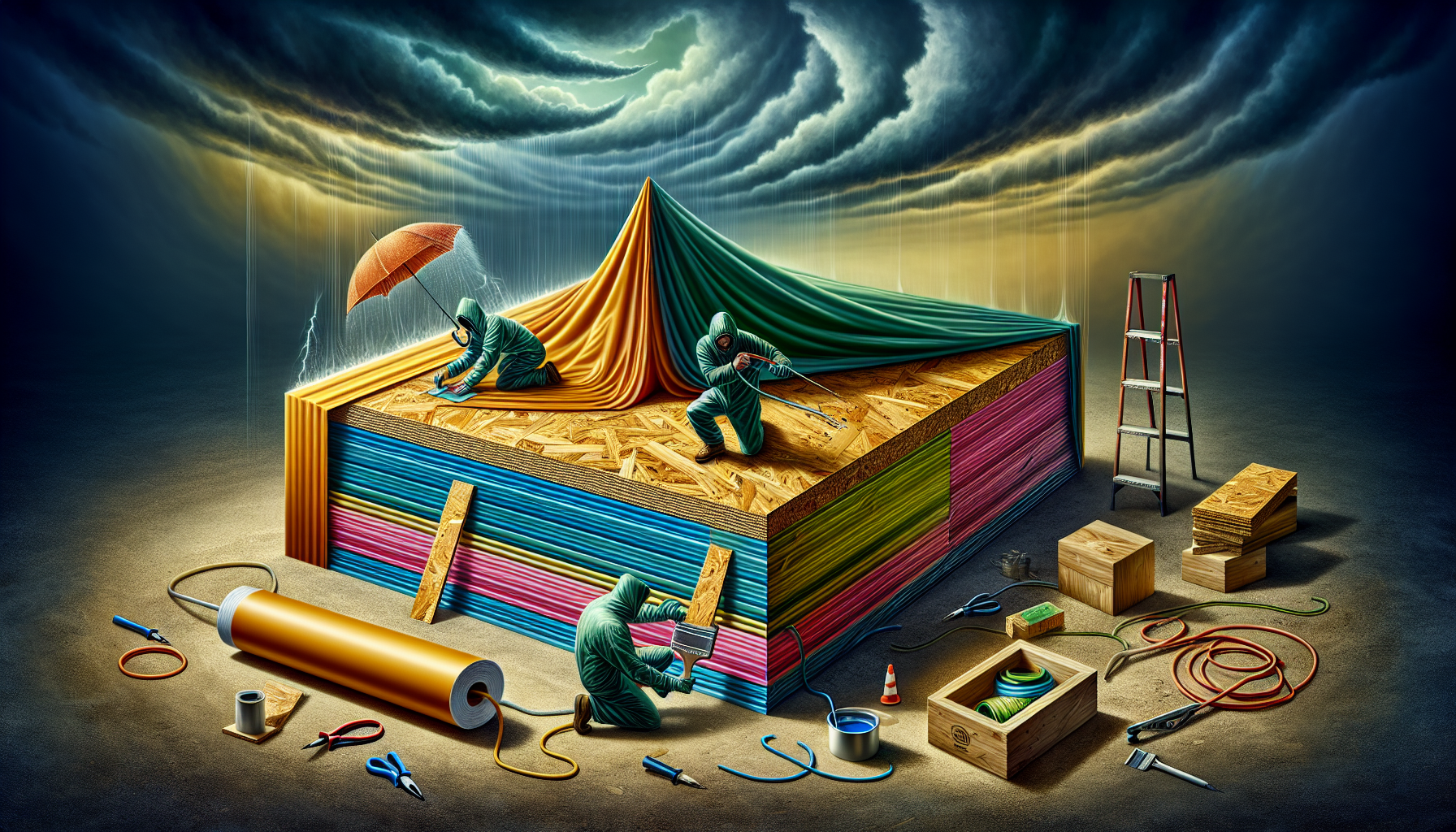

In addition to sealing, there are other ways to protect your OSB boards from weather elements. One method is to cover the OSB with a weather-resistant barrier, like Tyvek. Alternatively, vinyl siding, an affordable and straightforward material to install, can provide an additional moisture-resistant barrier.

Vinyl siding is protective and suitable for do-it-yourself projects, making it a popular choice for homeowners and builders alike.

Tarp and Caulk

When you need temporary protection for your OSB, covering it with a tarp and sealing edges and joints with caulk can prevent moisture damage. This approach is beneficial during construction when OSB is exposed to the elements briefly before being covered with permanent materials.

Ground Clearance

Maintaining proper ground clearance is another crucial aspect when working with OSB. Keeping your OSB panels at least 6 inches from the ground is essential to prevent moisture from rising up from the ground. Adequate ground clearance reduces the risk of water damage and the potential for costly repairs.

This clearance allows for sufficient air circulation to keep the panels dry, reducing the chances of moisture-related issues like swelling and mold growth. Lack of proper clearance can compromise the OSB panels’ structural integrity, so you don’t want to overlook it.

Exposed Edges

Lastly, sealing the exposed edges of OSB boards is critical to preventing water penetration and ensuring complete protection against moisture. Remember, moisture absorption in OSB usually occurs more rapidly at the edges of the panel, leading to swelling. So, don’t ignore those edges!

Enhancing OSB’s Durability with Additional Treatments

Beyond sealing and protecting OSB from weather elements, specific treatments can further enhance its durability and moisture resistance. For example, using water-resistant OSB products with added waxes and resins can improve their resistance to moisture, including preventing edge swell and moisture-related damage. Some advanced treatments, like LP WeatherLogic Air & Water Barrier, provide an integrated water-resistive overlay that combines the functions of sheathing and a water barrier, thus enhancing moisture management.

OSB can also benefit from treatments that manage thermal and heat resistance, as exposure to high heat can affect its ignition point and structural integrity. For extended durability, sealing all cut edges with a suitable preservative and using quality paint are additional steps that contribute to protecting OSB panels.

Wax Coating

A wax coating is one of the treatments you can consider for your OSB boards. Here are some benefits of using a wax coating on OSB:

- Enhances water repellency

- Reduces thickness swelling during short-term water exposure

- Waxes with a high melting point form more effective water-repellent barriers on OSB than those with lower melting points.

Interestingly, a blend of polar beeswax with nonpolar waxes like paraffin creates superior water-repellent barriers on OSB compared to solely hydrophobic wax components. So, a blend might be your best bet for a wax coating.

Foam Insulation

Foam insulation is another treatment that can boost the performance of your OSB. When applied to OSB, it enhances thermal resistance and contributes to a building’s overall energy efficiency by preventing heat from moving in or out of a structure. When applied outside the OSB’s studs, Continuous insulation with foam creates an uninterrupted insulating layer that reduces thermal bridging, a common issue in traditional stud framing.

Some innovative sheathing products, like LP NovaCore Thermal Insulated Sheathing, combine OSB with foam insulation. These offer an installation-friendly solution with an R-value of 5 per inch of thickness, providing insulation and structural support.

Siding Materials

Siding materials can also be attached to OSB panels to shield them from weather elements, extending their lifespan and enhancing durability. As mentioned earlier, vinyl siding is a practical and efficient option for covering OSB to protect against moisture.

It provides a cost-effective and DIY-friendly solution for adding a moisture-resistant barrier to OSB panels.

Common Issues with OSB and How to Address Them

Despite all the preventative measures and treatments, OSB boards can still encounter some issues. Regular maintenance is essential for preventing swelling, mold, and material degradation. Maintenance tasks include periodic inspections for any form of damage and thorough cleaning. Inspections should look for wear, water damage, or any deterioration that could impair the effectiveness of waterproofing.

If you find areas where the OSB boards have sustained damage or show signs of water intrusion, touch-ups with compatible waterproofing products are necessary. Now, let’s delve deeper into some common issues you might encounter.

Swelling

Swelling is a common issue with OSB boards. This typically occurs when the boards absorb moisture, making them thicker. This can result in a loss of structural integrity, with the layers of the boards potentially separating, further weakening the board’s structure.

It is crucial to maintain proper ground clearance, seal exposed edges, and ensure that your OSB is adequately protected from weather elements to prevent swelling. Additionally, using water-resistant OSB products or applying treatments like a wax coating can enhance moisture resistance and reduce the risk of swelling.

Mold Growth

Mold growth is another issue that OSB boards are susceptible to when exposed to prolonged moisture. This can compromise air quality and the board’s strength. To address mold growth on OSB, several cleaners can be used, such as:

- A mix of boric acid and hydrogen peroxide

- TSP

- Spray Nine

- Sporicidin

Remember, the best way to prevent mold growth is to keep your OSB dry. Regular inspections, proper sealing, and timely water damage repairs can help.

Material Degradation

Lastly, material degradation is a significant concern with OSB. Exposure to moisture can lead to swelling, delamination, and eventual structural weakening. Even UV radiation can damage OSB, breaking down the lignin, a natural polymer that holds the wood fibers together, leading to material degradation.

Furthermore, chemicals found in adhesives and sealants can react negatively with OSB, causing material degradation over time. To prevent this, it’s crucial to use compatible products when sealing and treating your OSB and to ensure that your OSB is protected from prolonged exposure to UV radiation.

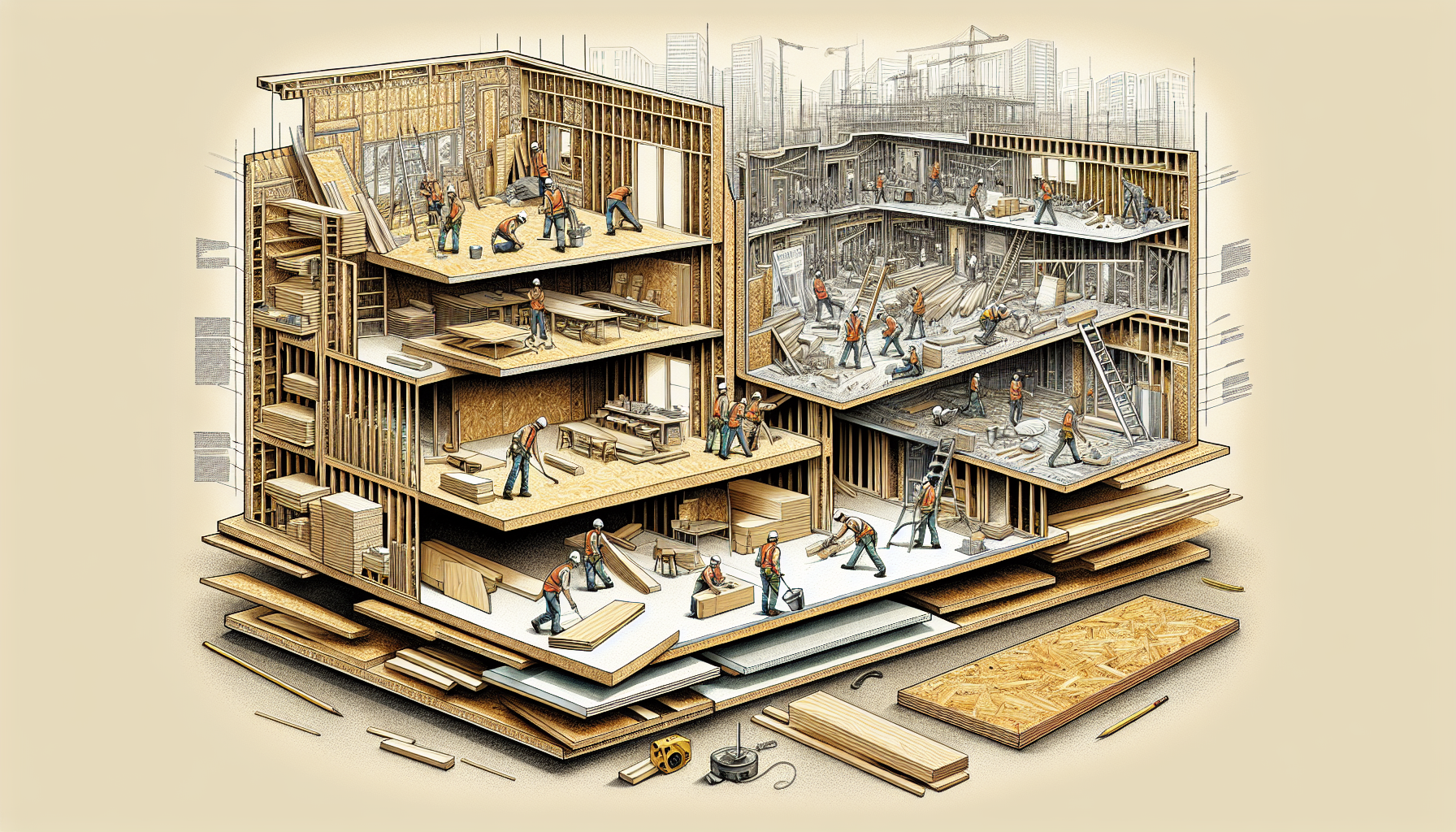

Interior and Exterior OSB Applications

You’ve probably gathered by now that OSB is a versatile material with various applications. In interior settings, OSB boards are used as substrates for laminate flooring, furniture production, and stylish industrial paneling for walls and ceilings. They’re even used in DIY projects and in constructing strong I-joists in flooring systems, with certain types specifically engineered for moisture-prone areas such as bathrooms and kitchens.

When it comes to exterior use, OSB is frequently employed for:

- Wall sheathing

- Flooring underlayment

- Roofing material

- Exterior siding material

- Making trailer liners and floors for recreational vehicles

However, it’s crucial to remember that OSB should not be in direct contact with moisture sources like soil or rain, as it can become blocked.

Expert Tips and Tricks for Working with OSB

Before we wrap up, let’s share some expert tips and tricks for working with OSB. First up, safety. When working with OSB, gloves and a face mask are recommended to avoid irritation from the board’s material. And don’t forget eye protection, especially when cutting OSB with power tools.

A sharp, sturdy saw ensures precise and clean cuts when cutting OSB boards. For projects exposed to moisture, select OSB boards rated for their compressive strength to ensure durability and resistance to swelling.

Summary

In summary, OSB is a versatile and cost-effective material widely used in construction. However, adequate care should be taken to ensure its durability and longevity. From choosing the right sealer and proper application techniques to additional treatments, regular maintenance, and understanding common issues, a lot goes into keeping your OSB in top shape. However, with the appropriate knowledge and a proactive approach, your OSB can stand the test of time, providing you with reliable and resilient building material for years to come.

Frequently Asked Questions

What is OSB, and what is it used for?

OSB, or Oriented Strand Board, is a compressed wood product used in construction for sheathing, subflooring, roofing, walls, and ceilings. It’s a versatile material for various construction applications.

What is the difference between oil-based and water-based OSB sealers?

Oil-based sealers provide a more resounding seal but take longer to dry, while water-based sealers dry faster but may not penetrate as deeply and emit a weaker odor.

How do I properly apply an OSB sealer?

To properly apply an OSB sealer, clean the board, fill the gaps, and lightly sand the surface. Then, use the sealer evenly, including edges and joints, and allow it to dry as per the manufacturer’s instructions. If needed, add more coats for complete coverage.

What are the common issues with OSB, and how can they be addressed?

To prevent common issues with OSB, such as swelling, mold growth, and degradation, conduct regular maintenance, such as periodic inspections, cleaning, and timely repairs with waterproofing products. This will help keep your OSB in good condition for longer.

What are some ways to enhance OSB’s durability?

To enhance OSB’s durability, consider sealing it properly and adding wax coating and foam insulation treatments. Covering OSB with siding materials or a weather-resistant barrier like Tyvek can protect from weather elements, ultimately extending its lifespan.