A lattice fence panel is any panel made of wood strips or laths. Such laths are normally crisscrossed on a frame in a symmetrical pattern. The pattern is usually a square or diamond pattern.

Some lattice fence panels are constructed in a floral and foliage design, but these are less common. Square lattice panels generally offer less privacy in a backyard than the other patterns. This is because the holes in the design make lattice partially see-through.

Square lattice fence panels make a great fence for front and back yards. They are long-lasting (when built and installed properly) and can boost the curb appeal of a house due to their pleasant aesthetic.

It’s possible to build lattice fence panels from plywood sheets. This can be cheaper than buying lattice new but requires some experience to get the design right. They also need to be installed properly to ensure the panels withstand all weather and don’t breach US building codes.

Keep reading to learn how to use, install and build square lattice fence panels.

What is a Square Lattice Fence?

A square lattice fence refers to the pattern on the panel. Square lattice has a square, crisscrossed pattern, while a diamond lattice fence has a square pattern that’s been rotated 45 degrees.

Commercially manufactured lattice panels are made from cedar plywood lath or molded out of vinyl or PVC plastic. PVC can be somewhat problematic in hot climates, as the plastic tends to dry out, leading to cracks.

Because of this, it’s more common to find lattice fence panels constructed of plywood. Most lattice fences can last up to 30 years, provided the wood is routinely treated and the panels aren’t exposed to heavy impact (like strong winds, adverse weather, or ball games).

Different types of lattice panels can be ordered through home improvement centers, like Home Depot and Lowes. Plywood sheets can be purchased at most general improvement stores. Stores like Lowes and Home Depot cut plywood for you, usually free of charge when buying the panel from the store.

Can You Use Lattice as a Fence?

In short, yes, you can use square lattice as a fence panel. It’s best used to hide service equipment in a tidy, aesthetic way, such as air conditioning units or swimming pool generators. They can be erected as a full fence or a garden divider.

Square lattice panels can also be used as a traditional fence. However, they are not as strong as other fence panels, like solid wood panels, vinyl, or aluminum.

You should also be mindful of neighbors when installing square lattice fences in the backyard. Because lattice tends to be see-through or partially visible, this can impact the privacy of a yard.

Other uses of lattice in the yard include:

- Decorative trellises or plant climbing trellises

- The top part of a fence (for decorative purposes)

- Skirting decks for homes built on a pier

- Pool enclosures

- Decorative walls for gazebos

- Arbor’s

- Pet enclosures, like chicken coops or Guinea pig pens

Now a modern yard feature, the first use of lattice goes back centuries. Before being constructed of wood, lattice panels used to be carved of stone. They were frequently used in medieval and renaissance gardens, and in French architecture.

What are the Dimensions of a Lattice Fence Panel?

Wood lattice is made of lathing strips, which are thin strips of wood that are between 7/16” to ½” thick and from ½” to 2” wide. Plywood sheets come in a range of thicknesses and can be cut to size to create the laths.

The most commonly used size for lattice fences is ¼” thick and 1 ½” wide. The best sizes for lattice fence building are 2’x 8’ or 4’x 8’. Typically, the lath used in making lattice panels is rough cut and not sanded. The plastic versions have wood grain molded into them to imitate wood panels.

The table below shows what size plywood is needed to build lattice fence panels.

| Square Lattice Panels | Common Dimensions |

| Heights | 5ft, 6ft, 8ft |

| Thickness | 2 x 8 inches 4 x 8 inches |

| Widths | ½ inch, 1 inch, 1 ½ inch, 2 inches |

| Lathing Strips | ¼ inches thick x 1 ½ inches wide |

Can You Make Your Own Lattice Panels?

Most people buy lattice panels, but that doesn’t mean they can’t be made in the home workshop. Lattice panels are quite easy to make, although somewhat tedious, especially if a lot of them are needed.

To make lattice panels, you need to decide:

- How big will the panels be?

- How big will the lath strips used to assemble the panels be?

- How much space will there be between the strips?

- Will the strips be attached together to form squares or diamonds?

Most fence panels are between 5ft to 6ft in height and width. You can choose how large the lath strips are. It’s best to use strips that are between ¼ inches thick x 1 ½ inches wide for a premium look.

Spacing between the strips can be mismatched or even. It’s common to leave a space that’s the same width as the lath strips.

To build a square lattice fence, lay the lath strips horizontally or vertically. To build a diamond lattice fence, lay the strips at a 45-degree angle.

Is It Cheaper to Make Your Own Lattice?

Making your own lattice fence is cheaper than buying premium pre-cut wood. Cedar is the cheapest wood for lattice fence panels. But the best type of plywood to use is pressure-treated yellow pine. This tends to be more resistant to water and insects.

You can also use redwood, or mahogany, although these tend to be more expensive. These have a more attractive color (like deep red or reddish-brown) but are not as resistant to the weather.

| Type of Wood | Price Per Sheet | Color |

| Cedar | $8-10 | Pinkish Red |

| Pine | $13-22 | White or Pale Yellow |

| Mahogany | $15-35 | Reddish-Brown |

| Redwood | $20-40 | Dark Red |

Remember, when using pressure-treated wood, you’ll still need to seal cut edges to prevent wood rot. Paint wood panels before construction (but after cutting) or use a high-quality outdoor wood stain.

How Do You Make Homemade Lattice?

To make square lattice panels, you’ll need:

- Plywood panels

- Tape measure

- Table saw or band saw

- Paint, stain, or other finish

- Paintbrush or paint roller

- Staple gun

Here’s how to make homemade lattice fence panels.

1. Cut Panels Into Strips

First, you should cut the panels into strips. All strips should be the same size for ease of cutting. A typical size for lath strips is ¼” thick by 1 ½” or 2” wide. Choose the thickness that suits your preference.

Thicker strips are stronger and more durable. They can also offer a more premium aesthetic. Thin lath strips can produce a daintier aesthetic but may not be as strong.

Cut lath strips using a table saw or band saw. Using a band saw prevents wastage of wood during cutting and is the best choice, if available.

Remember, lath strips don’t need to be spaced evenly apart. They can be fitted using staggering widths to create a mismatched pattern.

For example, the standard spacing between strips can be the same as the width of the strips, and then every third strip can have double the spacing. This can give a “plaid” design to the panel.

2. Stain or Paint the Strips

For ease, it’s often best to paint or stain the strips before attaching them to the panels. This ensures an even finish is applied. It also ensures that all cut edges are suitably treated against water exposure.

Applying paint, stain, or another treatment to square lattice panels after construction can leave some cut edges exposed. This leaves the strips subject to warping from water damage.

To paint lattice panels or strips, use an airless paint sprayer or paint by hand. When painting plywood by hand, lay the lath strips on a table and use a roller to cover the front faces and a paintbrush for the edges. When dry, flip the lath strips and repeat.

3. Connect Panels Together

A large table or workbench is needed to assemble the panels together. Lay the connection points on all the perimeter pieces. Place one piece across the center.

Lay the cross pieces over the top of the pieces and staple them together at each marked intersection (on the edges and the center crosspiece). Use a staple gun.

Once all the cross pieces are attached, attach the long pieces in the same way, stapling at every end joint and the center crossbar.

How to Install Square Lattice Panels

There are several ways that lattice panels can be installed, depending on the effort and expense that one wants to put into them.

Since the lattice panels themselves have very little structural integrity, they need to be secured in a way that gives them structural strength.

To do this, you can either:

- Attach the panels to the framework where the lattice is to be installed

- Install frames to the panels

- Install a U mold around the edge of the panel

1. Attaching Panels to a Framework

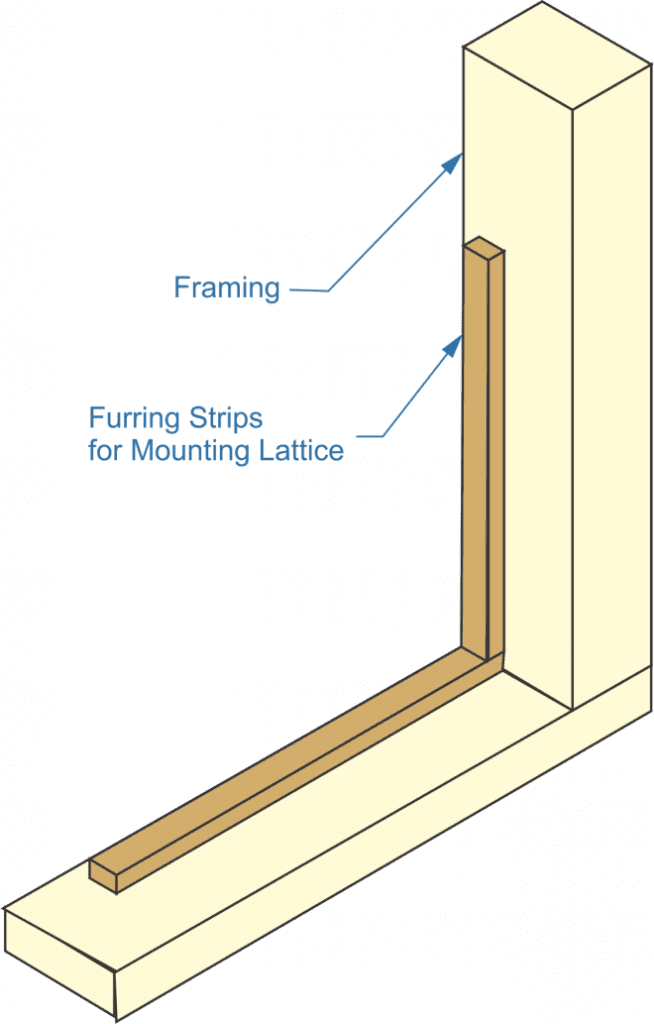

In most cases, the framework is built for the lattice to be attached to. This can be a 2”x 4” framework, but it often includes furring strips that have been attached to the structure of what the lattice panels are being used in conjunction with.

If the lattice panels are being used as skirting for a deck, for example, then the lattice can be attached directly to the deck’s framing. Or furring strips can be attached to the deck’s framing for the lattice panels to be attached to.

The second option is extremely useful when the support is not provided in the right direction for the panels to attach to. It also makes the framing around the lattice panel more attractive.

A second course of furring strips can be added on the outside of the lattice. This should cover the ends of the lattice and hold it in place, while framing it attractively.

2. Attach the Frame to the Lattice Panel

Another option is to attach the frame directly to the lattice panel. Then, use that frame to attach the lattice panel to whatever structure will be behind it.

This can be done by using 1”x 3” or 1”x 4” dimensional boards, attaching them to the face of the lattice panel, all the way around the edges.

As with the abovementioned method, the easiest way to attach the two together is with narrow-crown staples from a pneumatic stapler.

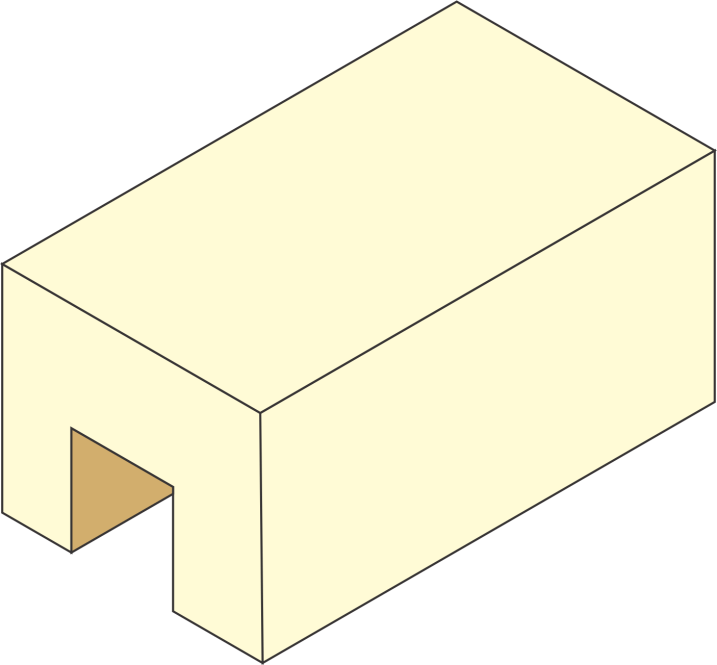

3. Install a U Mold Around the Edge of the Panel

A third option is to buy U-mould capping to go around the edges of the lattice panel to frame it. However, not all lumberyards and home improvement centers supply U molds.

Nevertheless, any woodworker with a basic shop can easily cut their own. The U mold is simply a square wood stick with a groove cut into one side. This groove allows the lattice to be inserted and fastened.

The corner of the U mold can either be square, as pictured, or cut with a radius router bit.

Summary

Square lattice panels make a great front or back yard fence. They are cheap, easy to install, and offer a pleasant aesthetic to a property. You can build lattice fence panels from Cedar plywood or pressure-treated plywood (that’s suitable for outdoor use).

Or lattice panels can be bought from general home improvement stores, like Lowes or Home Depot. Building lattice fence is usually cheaper than buying pre-made panels. When building lattice from scratch, ensure you use the right type of plywood and apply a nice finish to waterproof plywood and protect it from all weather.