Walk into worship space in any church, and one will find one of the defining things about worship space that stands out is the pulpit.

Typically set in the middle of worship space behind the altar area, the pulpit you find in worship space is where the preacher expounds, bringing home his lesson on the Bible to the congregation. These pulpits you find in worship spaces can vary considerably in appearance, showing a bit of detail of the unique personality of that church.

Acrylic wood pulpits have become popular in more modern churches, providing an uninterrupted view of the preacher. However, most traditional churches still use and stick with the warmth and beauty of a wood pulpit, even if it is designed in a modern style.

One of the nice things about homemade wood pulpits is that a home or member can use them at the home church if a woodworker attends that particular home church. While plenty of houses and companies manufacture wood pulpits, commercially, small home churches, especially those just starting, usually operate under severe financial constraints.

Finding a home with a member willing to build a homemade wood pulpit saves the home church money, which can be used for other things.

The same can’t be said for acrylic, metal, and other materials also used in making wood pulpits here. At the same time, working on wood pulpits with these materials in a home workshop may be possible. There aren’t as many home business people accustomed to wood pulpits or doing business with that business as home woodworkers.

Typically, churches will order wood pulpits made of those materials from a retail vendor selling wood pulpits made in a factory.

Pulpit’s Podiums & Lecterns

Although we use the term “pulpit” to refer to the lecterns, the standing desk or lecterns that the lecterns preacher stands behind in a church, that’s a bit of a misnomeInitiallylly, the term “pulpit” referred to the lecterns, raised stand for the pulpits of preachers in a church.

It was where the lecterns the preacher gave his message or sermon, and the lecterns or pulpits were often rather ornate.

Churches might also have lecterns, a more undersized, less busy raised stand for lecterns for use by others, or lecterns even lay persons to the pulpits and do a reading called lecterns “lectern.”

Yet today, most churches don’t have the use as worship space of these raised podiums or stands. Instead, they use them. A few stages are placed on the altar or in the front of the church in an area referred to as the altar area, even though it isn’t in use of worship space as a raised platform. It is used as a worship space to expound on the scriptures, so it retains the name “pulpit.”

Leaving the church behind, we find the terms podiums and lecterns used in higher education, banquet halls, and conferences.

In those contexts, the name podium is a raised platform the speaker stands upon. While not raised as high as the pulpit in a church would generally be not ornate, the modern podiums bring to primacy the person speaking.

Name lecterns are placed upon these podiums for the speaker to put their notes on and stand behind. The name lecterns is often used without the name podiums, though, such as in lecture halls.

Designing a Wood Pulpit for a Church

Wood pulpits can vary considerably in both size and style. While they are about 48″ tall, they can range from about 16 inches to 8 feet wide.

The larger ones would only be used in larger churches with worship space, while small churches would typically limit worship space to two wood pulpits per worship space or find something on the smaller end of that scale to find a worship space.

Speaking as an experienced preacher, there are definite advantages over having a slightly larger pulpit. In the past, most preachers went to the pulpit with a Bible and notepad. Fitting both on a 16″ wide pulpit meant moving them back and forth to uncover what was needed.

While most preachers use a tablet today, with the Bible verses they will use copied into their notes, it is still common to carry a printed Bible into the pulpit anyway. So the need for a wider pulpit hasn’t gone away.

Even in cases where you find the pastor uses a tablet for their preaching notes and doesn’t choose to bring along a printed Bible, we find it’s still helpful to provide him with a broader pulpit and another one for visiting preachers who still prefer to use those older methods. It’s also a good idea to offer him to find someplace for a water bottle and provide hidden storage space for items he needs behind the pulpit.

The top of a wood pulpit also is universally sloped to provide an easy-to-use book rest. While different wood pulpits sometimes might choose to be made with a different slope giving the book rest their use needs, they are mostly 15 to 20 degrees, with a lip on the bottom edge to keep things from sliding off.

Another way pulpits might vary is whether there are sides for items on the bookrest. Some pulpits have boxed-in sides, preventing things such as Bibles and notes from falling off the sides. Others have side sections, which provide items with a small boxed-in shelf on both sides of items on the pulpit, where things such as water glass might be set. While functional, these items are more decorative than they provide anything else.

Depending on the needs of the church, the front of the pulpit might choose to use or not choose to be adorned with the church’s logotype or some Christian symbol, such as a cross. This is not a requirement but rather something done for decorative purposes.

Churches that use it to live stream their services will almost always choose to put the logo on the front of the pulpit to be readily visible to those watching online.

Before deciding on a final design for the pulpit, it’s a good idea to look in detail at pulpits in various churches and see their needs and how they use or are done. Most pastors or preachers will have specific needs or ideas of what they want for their pulpit.

While they will be appreciative of anything that someone builds for them, they will be more appreciative of a pulpit being something that is built to meet their specifications.

Building a Wood Pulpit

A bare wood pulpit can be built from a single sheet of ¾” hardwood plywood, a few sticks of matching hardwood for the pulpit trim, and some matching hardwood veneer shelf edging. Some softwood is also needed for support on the inside of the wood pulpit and the wood pulpit itself.

One thing one needs to remember is that wood pulpits can receive a lot of rough handling, so it’s necessary to use something to brace the wood pulpit and joints, helping to ensure that it doesn’t fall apart.

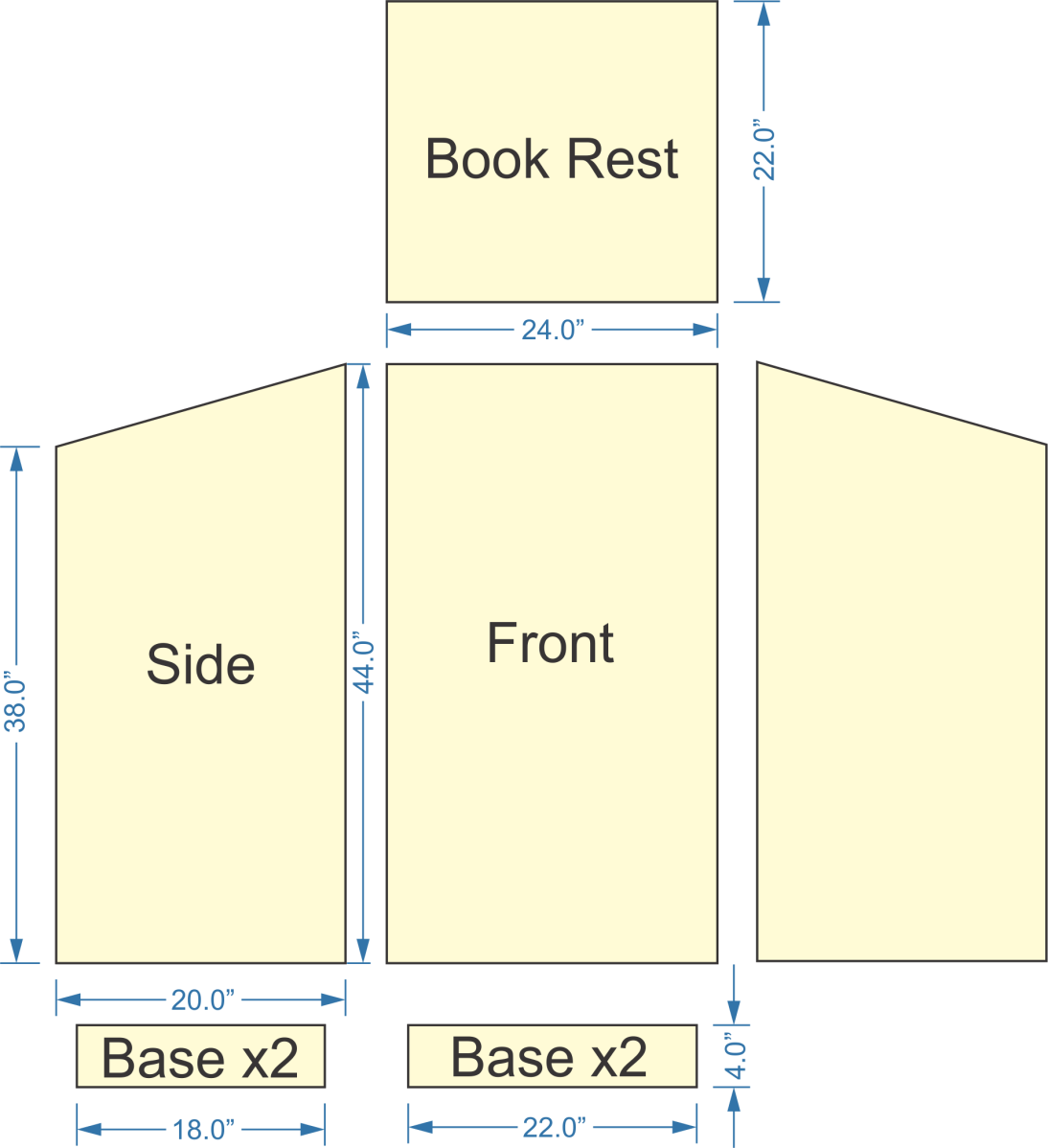

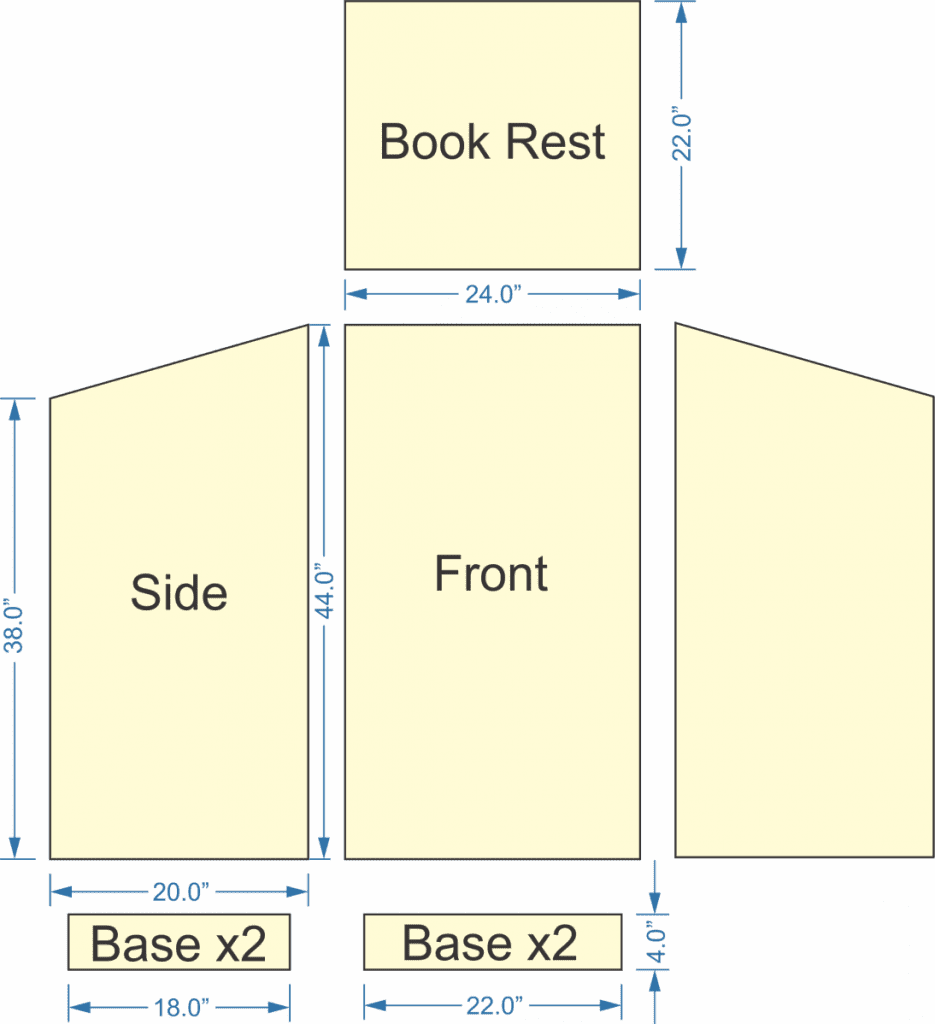

Start by cutting the sheet of plywood, as shown in detail below. No allowance or component has been made for the saw kerf, and the dimensions and details are only approximate. A

Adjust them as needed to provide for the needs of the pulpit being made. It can be larger or smaller as the needs of the various needs and conditions are desired; the primary purpose of the drawing and detail is to provide and show the relationship between the needs of multiple pieces’ sizes and needs.

Dimensions

Since this is hardwood plywood we’re talking about; care should be taken in cutting to ensure the hardwood face veneer isn’t damaged.

Remember that the face, reverse veneers, and wood pulpits are not the same grade. So when it comes to the sides and wood pulpit, they need to be cut opposite each other to maintain the face veneer on the outside of the wood pulpit only.

In many cases, such a piece of furniture would be assembled using finish nails or pocket screws, along with glue. While that could also be workable, it would produce a pulpit that isn’t all that resilient to breakage when moving it.

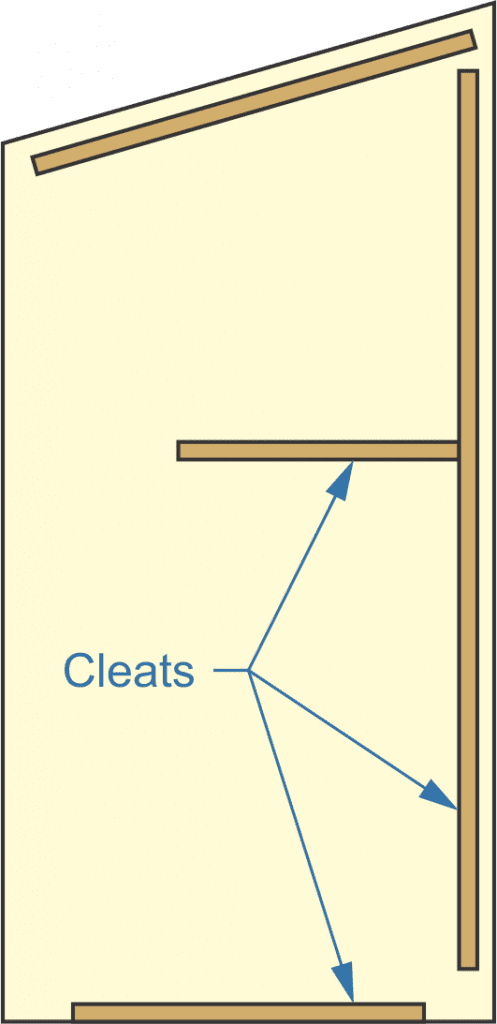

Therefore, it would be a good idea to use joining cleats to attach the various pulpit pieces. These cleats can be glued and nailed to both adjoining pulpit parts. In addition, the pulpit elements can be glued and fixed to each other, providing something like a double joint, strengthening the pulpit.

The diagram below shows how these would be located on the inside of one of the sides. Something similar would be done for the inside of the front, less the corner pieces.

Cleats

While it is possible to buy a ¾” square strip for use in making the cleats or to buy square dowel rods for them, but find it’s considerably cheaper to buy a standard piece of 1″ thick dimensional lumber and rip it into ¾” strips on the table saw for this.

I find to do that often enough always to have some already ripped strips sitting in the lumber rack of my workshop.

The first thing that should be connected is attaching the front and sides. Once they are in place and secured, the top, bottom, and middle shelves can be added.

At least one middle shelf should be installed to help hold the pulpit rigid, although extras can be installed if desired. Avoid nailing through the sides of the pulpit into the shelves, as those holes will be hard to hide. Instead, attach them to the cleats.

The pulpit base comprises four pieces of plywood, formed into a box and then attached to the pulpit or podium’s bottom shelf. Since the inside of the pulpit is accessible, it’s easy to go through the bottom bracket into the edges of the wood pulpit base to attach it.

While those nails or screw holes might be visible, they will only be visible to someone standing behind the pulpit, so it’s not all that important.

Be sure to add floor-leveling feet to the base of the pulpit, as the altar area of a church, podium, or pulpit is not always level and even, especially in an older building.

A pulpit that rocks back and forth while the pulpit is used can distract the preacher and the congregation.

Once the essential wood pulpit part is assembled, it’s time to choose a finish and adorn it as desired. At this point, the edges of the plywood are still visible, something that needs to be taken care of.

The simplest way of doing that is by using wood veneer shelf edging.

Assuming the same kind of edging as the plywood, this iron-on product will give a clean edge, making it look like the plywood is solid wood.

Rather than using veneer edging on the front corner of the pulpit, another option is to use wood architectural molding. Something would be needed that is designed to go around a corner, but there are molding styles that do that.

This detail would add to the overall appearance of the wood pulpit top, making it more formal. A similar molding or ripping the same molding can be done to make the stop at the bottom of the bookrest so that items of books and papers can’t slide off the wood pulpit top.

Adding a logo or other symbol to the front of the pulpit isn’t mandatory, but it is still a good idea. This can be routed into the plywood, laser etched, or made separately and then attached.

For those cases where the pulpit is made separately and then attached, it’s best to apply the stain and varnish before attaching it.

However, the methods that cut or burn into the plywood pulpit should be done before finishing. It’s the easiest to do those before assembling the whole wood pulpit.