Walk into any modern kitchen or peek inside a custom-built cabinet, and you’ll see a neat, finished look along the exposed plywood or MDF edges. That sleek finish isn’t magic—it’s edge banding.

Edge banding is an essential woodworking technique that conceals rough plywood or MDF edges, making your project look polished and ready for showroom floors. Whether you’re a weekend DIYer or a seasoned woodworker, learning how to apply edge banding can completely transform your projects.

In this detailed guide, we’ll walk you through:

- What edge banding is and why it matters

- Types of edge banding (and which is best)

- Tools you’ll need (with top Amazon picks)

- Step-by-step instructions

- Common mistakes and pro tips

- Where to buy quality edge banding materials

- Maintenance and long-term care

Let’s start at the beginning.

🪵 What Is Edge Banding?

Edge banding is the process of covering the exposed edges of sheet goods like plywood, MDF, or particleboard with a thin strip of material. This not only improves the appearance but also protects against moisture, chipping, and delamination.

Materials used for edge banding include:

- PVC (plastic)

- ABS (eco-friendlier plastic)

- Real wood veneer

- Melamine

- Acrylic

Edge banding is commonly used in:

- Cabinet construction

- Furniture manufacturing

- Interior shelving

- Custom desks and countertops

🔗 Related Read: Best Plywood for Cabinets

🧱 Why Edge Banding Matters in Real Woodworking Projects

The first time I built something out of plywood, I was genuinely proud of it—until I stepped back and looked at the edges. Everything else was solid: the joints were tight, the surfaces were flush, and I’d even taken time to sand it carefully. But those raw, layered sides? They completely gave away the fact that it was made from sheet goods. No matter what I did—paint, filler, even a little wood glue—they looked unfinished.

That’s when it clicked: you can’t ignore the edges.

It turns out that’s a lesson every woodworker eventually learns. Plywood is a great material—affordable, strong, stable—but every single cut exposes its inner layers. Unlike solid wood, which only shows end grain at the ends, plywood wears its insides on all sides. If you’re building furniture, cabinets, or shelving, that layered edge doesn’t just look raw—it cheapens the whole piece.

Edge banding solves that.

It gives you a clean line, seals off those exposed layers, and makes your work look intentional. Instead of highlighting the fact that it’s plywood, you’re telling the eye, “This is a finished surface.” And if you’re building anything modern or minimalist, where clean lines matter, edge banding is non-negotiable.

There’s also the durability factor. Raw plywood edges soak up moisture. They chip easily. With particleboard or MDF, the problem gets worse—they can swell and crumble just from humidity in the air. But with edge banding? You’re locking in the strength and protecting your project from everyday wear and tear.

Once I saw how much cleaner and more professional my projects looked with edge banding, I started using it on everything—from shelves and tables to storage cabinets in the garage. It’s one of those finishing steps that separates a decent build from something you’d be proud to show off or even sell.

📦 Types of Edge Banding

1. Pre-Glued Edge Banding (Iron-On)

This version comes with heat-activated glue. Just apply it with a household iron.

✅ Best For: DIYers, small shops

⛔ Drawback: Glue bond is weaker than commercial-grade options

2. PVC Edge Banding

Plastic-based and flexible. Popular in cabinet shops.

✅ Best For: Durability, water resistance

⛔ Drawback: Requires an edge banding machine

3. Wood Veneer Edge Banding

Thin strips of real wood. Perfect for high-end furniture.

✅ Best For: Staining to match surfaces

⛔ Drawback: More expensive and less flexible

4. Acrylic Edge Banding

Thick, glossy, and ultra-modern.

✅ Best For: High-gloss kitchens and modern cabinetry

⛔ Drawback: Expensive and requires special tools

🔗 External Source: Edge Banding Types Explained – Woodworkers Journal

🧰 Tools You’ll Need for Edge Banding

If you’re planning to install edge banding yourself, here are the essential tools:

| Tool | Description | Amazon Affiliate Link |

|---|---|---|

| Household Iron | For heat-activated edge banding | Buy on Amazon |

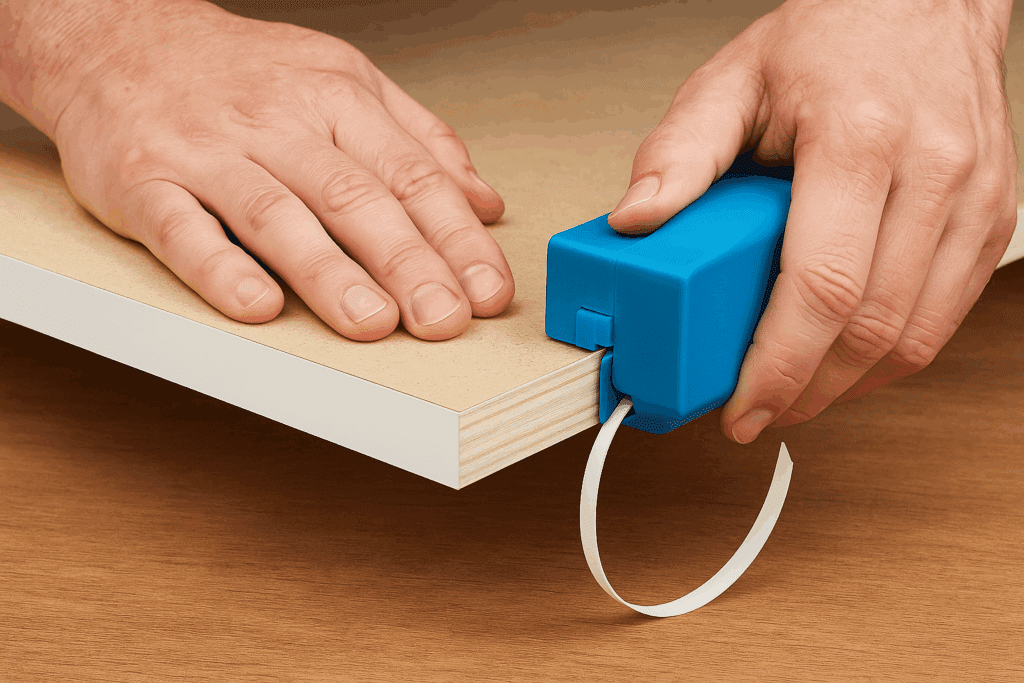

| Edge Trimmer | Trims excess banding for a clean look | Buy on Amazon |

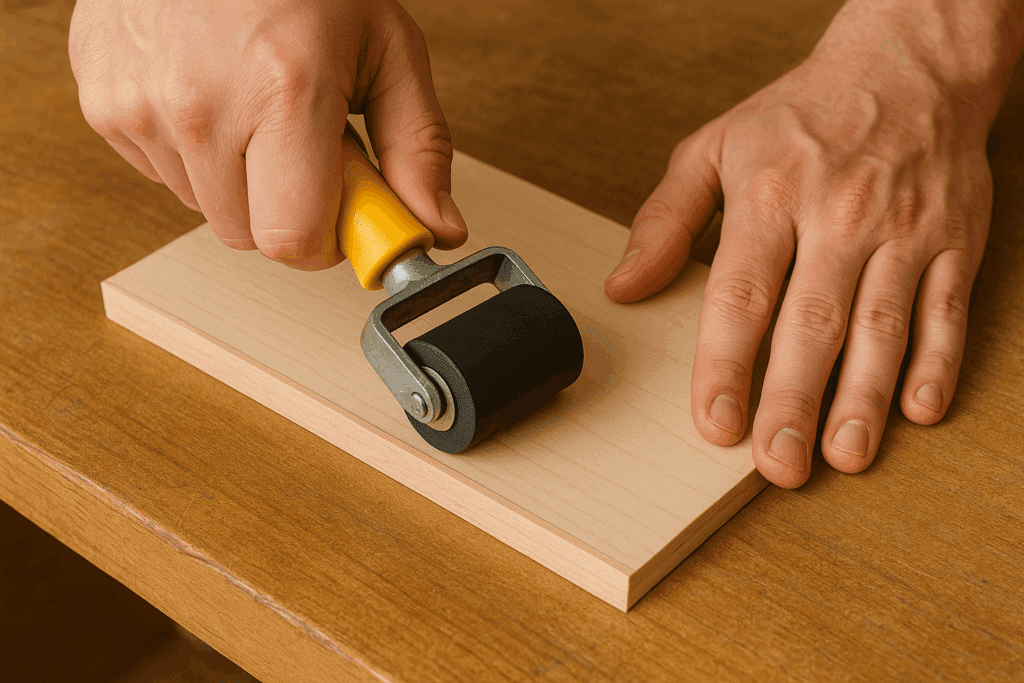

| Roller or Wood Block | Presses banding evenly onto the surface | Buy on Amazon |

| Sanding Block | Smooths edges post-application | Buy on Amazon |

| Utility Knife or Chisel | For cutting banding to size | Buy on Amazon |

🧑🏭 How to Apply Edge Banding: Step-by-Step

Step 1: Prepare the Surface

- Sand the plywood or MDF edge lightly to remove any burrs or dust.

- Wipe with a tack cloth to ensure the glue bonds well.

Step 2: Cut the Edge Banding

- Cut a strip slightly longer than your edge.

- Leave a 1/2″ overhang on each side to trim later.

Step 3: Apply Heat (Iron-On Only)

- Set your iron to cotton/no-steam setting.

- Place the banding and press the iron firmly over it for 20–30 seconds.

- Work in small sections to avoid shifting.

Step 4: Press It Down

Use a roller or a block of wood to apply pressure while the glue is hot. This helps ensure a tight bond.

Step 5: Trim the Edges

- Use a specialized trimmer or utility knife to cut excess overhang.

- Always trim downward to avoid splintering.

Step 6: Sand and Finish

- Lightly sand the edges for a flush, smooth finish.

- You can apply a stain or a clear coat for wood veneer types.

⚠️ Common Mistakes to Avoid

- Not cleaning the edge – Even a little dust ruins glue adhesion.

- Using too much heat – Can cause banding to bubble or discolor.

- Skipping the roller – Poor pressure leads to peeling corners.

- Cheap trimmers – Poor-quality tools tear the banding instead of cutting cleanly.

🛒 Where to Buy Edge Banding

You can find quality edge banding at:

- Amazon – Wide variety and fast shipping

Browse Edge Banding on Amazon - Rockler Woodworking – Great selection for specialty wood veneers

- Home Depot and Lowe’s – Good for basic iron-on strips

🔗 Internal Link: How to Make Plywood Look Like Oak

🧽 Long-Term Care Tips

Edge banding is durable, but it still needs care:

- Avoid soaking wood edges in water

- Use a touch-up marker for chips or scuffs

- Don’t drag heavy objects across furniture edges

- Re-glue peeling corners with contact cement

🔄 When to Replace Edge Banding

Replace edge banding if:

- It’s peeling or delaminating

- You’re refinishing the surface in a new color

- The banding is mismatched due to fading or wear

🔗 Related Article: How to Paint Plywood for a Smooth Finish

🧠 Final Thoughts: Is Edge Banding Worth It?

Absolutely. Whether you’re flipping furniture, updating your cabinets, or building from scratch, edge banding is a small investment with a big payoff. It instantly elevates your project, gives it a professional look, and helps your work last longer.

Once you’ve done it a few times, you’ll find it’s not intimidating at all—just another valuable woodworking skill in your toolbox.