The large size of plywood sheets (8’ x 4’ US; 125 x 250 cm metric) is ideal for rapidly constructing homes and completing home improvement projects. However, those large sheets also come with a few problems, most notably in how to handle them effectively. The combination of their large, awkward size and weight, with a ¾” (20 mm) sheet weighing up to 70 lbs (32 kg), can make them a challenge to handle, especially for the do-it-yourselfer who doesn’t handle them all the time.

Professional carpenters have an advantage over us do-it-yourselfers because they are more accustomed to handling those heavy sheets. While a 70-pound sheet of plywood is still a 70-pound sheet of plywood, professional carpenters always handle that, building muscle. Those of us who sit in an office all day and then go home to work on projects probably don’t have the same muscle mass.

Fortunately for us, several tools, tips, and jigs assist the home DIYer in handling these large, heavy, and awkward sheets. These jigs or handles are commercially available at your local home center or readily prepared using scrap lumber you probably have sitting around from previous jobs.

Panel carriers

The home DIY’er can purchase various items that all fit under the heading of ‘panel carriers.’ These carriers come in different prices to fit any budget, though even the most expensive versions won’t break the bank. We’re talking $7 to $50, depending on how good a one you want. All panel carriers have an essential “J” (or hook) shape where the plywood rests at the bottom of the hook with an offset handle for more convenient handling.

The less expensive models are nothing more than a piece of plastic with a narrow slot for a piece of plywood (or drywall). The narrow slot doesn’t afford tremendous control of such a large panel, and the thin plastic construction won’t win any durability contests. Nevertheless, this would suffice for the home DIY’er with only a few panels to move about, but you’ve got to remember that you often get what you pay for. These low-cost carriers will only last so long.

More robust and expensive carriers (like the Gorilla Gripper panel carrier) give additional support as the panel is locked between two padded jaws with an offset handle. It’s still awkward for someone working solo, but it is much more durable than the low-cost options.

Perhaps the best way to control a piece of plywood solo would be to use a plywood panel carrier with wheels; this product solves two problems at once— quickly moving an awkwardly sized panel and taking the strain off your back.

Making your carrier

Even though commercially available items are relatively inexpensive, home DIYers can easily construct their own panel carrier for little to no money out of scrap material or even just a piece of rope. Using rope to carry plywood is cheap, fast, and effective.

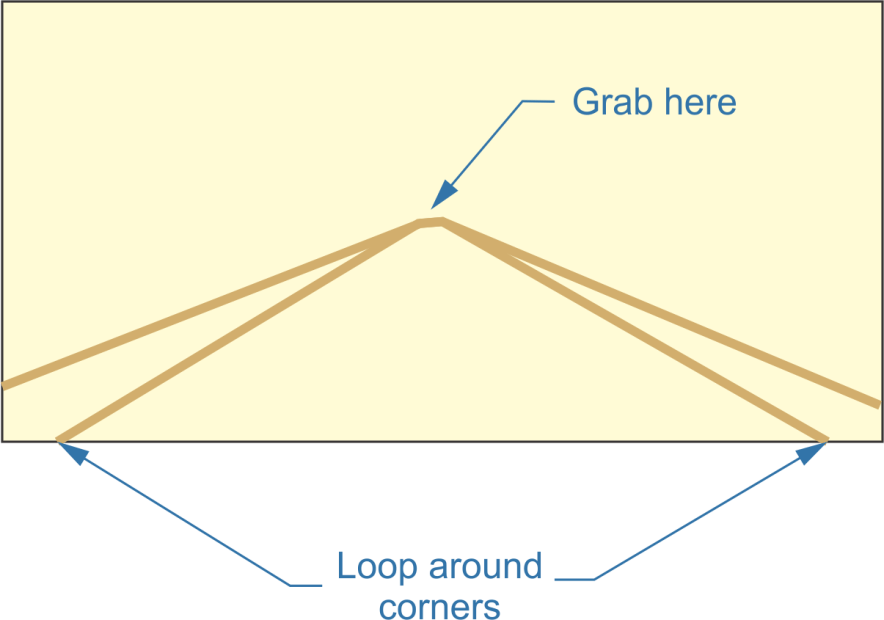

To make a rope carrier, tie approximately 20’ of rope (~600 cm) into one continuous loop. Place one part of the loop around each bottom corner of the plywood sheet, pulling the slack up to make a “handle” point in the middle of the sheet, as shown in the diagram below.

People needing to move plywood sheets up a ladder may also use this method. However, this is very awkward and can be dangerous.

The J-hook

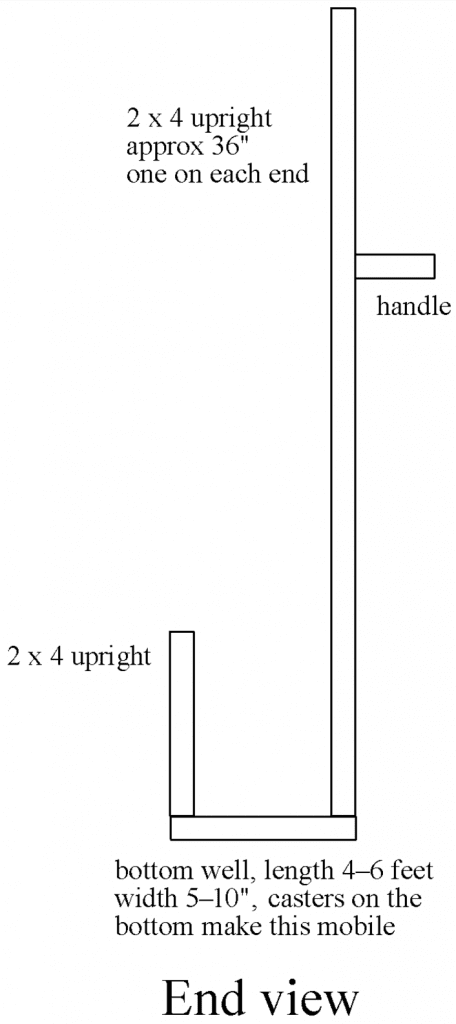

While the rope method mentioned above is probably the simplest way of carrying a sheet of plywood solo, it does have its limitations. More than anything, it is limited because it only works with one sheet of plywood at a time. However, using a J-hook, you can handle multiple sheets as long as you can handle the weight.

The basic design of the J-hood is shown in the section on the rolling panel carrier below. If you use it to carry plywood rather than with casters, you’ll want to make the well at the bottom of the J-hook smaller, as you won’t be able to stack that many pieces of wood at once.

Whether carrying it or putting casters on it, you must reinforce the joints at the corners. Just nailing or screwing them together probably isn’t going to be enough. The easiest way to strengthen them is to install metal corner brackets in addition to nailing or screwing them.

Another excellent way to strengthen these joints is to dowel them with normal ½” to ¾” dowel rods instead of the packaged short dowel rod pieces typically used for doweling. Those are less than 2” long, and we need something that’s at least 4”.

To dowel these, clamp, nail, or screw the corners together, keeping room open for the dowels. Then, drill through the board, forming the bottom portion of the well into the ends of the vertical 2”x 4” pieces, with the right-sized spade bit to match your hardwood dowel. You’ll want to use two dowel pins per connection. Point the end of the dowel slightly with your pocket knife, put glue onto it, and pound it into the hole until it bottoms out. Then, cut off the excess material with a flush-cut saw.

Rolling panel carrier

Making a rolling panel carrier is pretty straightforward for the home DIYer who wants to move panels at home with the ease and control found at the home center. It can be made inexpensively with standard materials. At its core, it fuses two J-hooks with a long (4–6’ or 120–180 cm) bottom well with casters at each corner. All you have to do to make this is attach two J-hooks at the bottom with a 2”x 4” or 2”x 6” board. Add casters at each corner to allow you to roll the carrier.

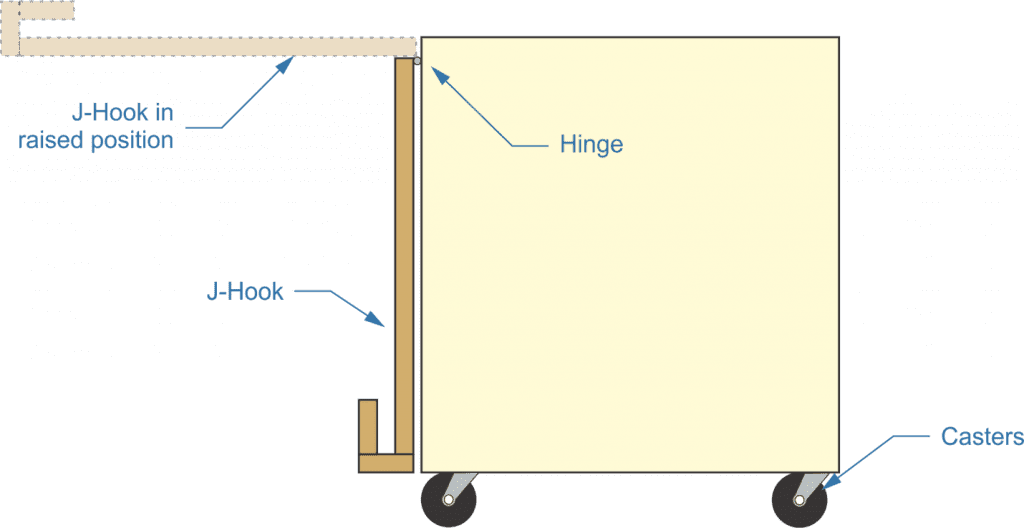

Going from vertical to horizontal

Another use for the H-hook is attaching it to a rolling workbench, allowing it to be rotated to the horizontal for work. If you make your rolling workbench the same height as your table saw, it can serve as an extension for your table saw as well.

This cart allows you to load sheets of plywood onto it with the J-hook lowered. In that position, the cart can be rolled to wherever you need it. Then, the J-hook can be raised, laying the plywood on top of the cart/workbench to work on it.

Making such a cart with storage inside would be a good idea, as there is never enough storage space in a workshop. Using that storage for your circular saw and a few other power tools would be convenient, as they would be readily at hand for working on your plywood. At the same time, the weight of the tools could counterbalance the plywood’s weight, helping to give the cart more stability.

Getting plywood onto your roof

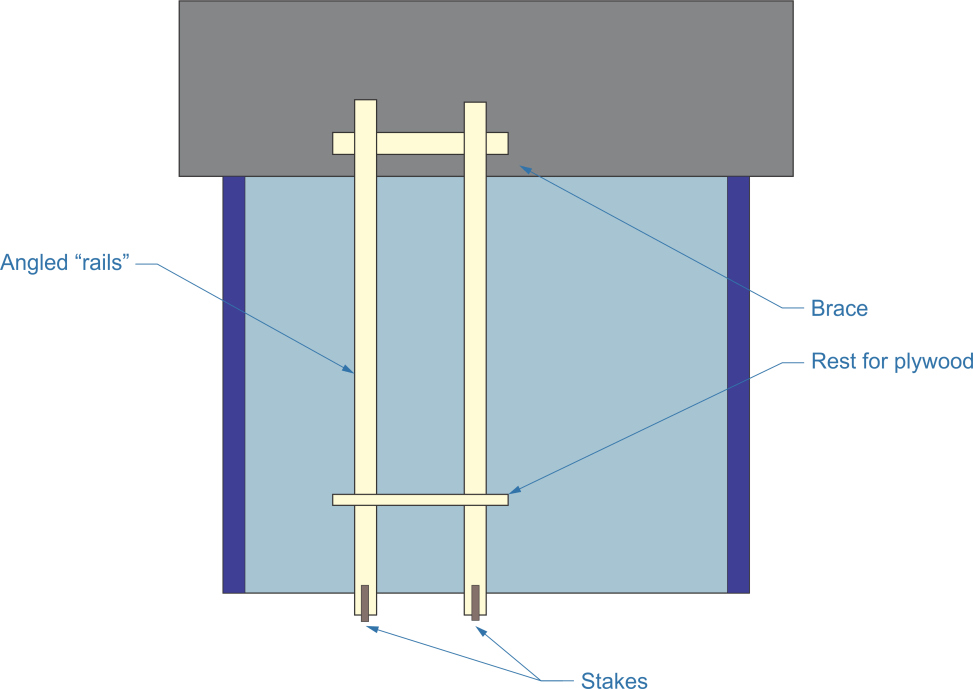

Rather than trying to carry a sheet of plywood up a ladder, with all the danger that such an action might incur, you’re better off turning this into a two-stage operation. To start with, lean two 2”x 4”s against the house’s eaves, two to three feet apart. Stake them at the bottom to keep them from moving. In addition, brace them on the back (building) side, near the top and at the bottom end, and add a 2”x 4” or 2”x 6”, mounted horizontally, to act as a material rest, roughly three feet above the ground.

With this setup, you can vertically set full sheets of plywood on the rest and then climb onto the roof to retrieve them. Since the rest is three feet above the ground, the top end of the sheets should be above the roof’s edge, allowing you to grab them and manhandle them up, sliding on the rails, onto the roof.

Another option is to have an assistant load the sheets onto the rest, one at a time, while you pull them off from above. This same sort of idea can work, even if you are trying to get the plywood onto a two-story house. You would need longer rails and some rope.

To do this, make a rope sling out of 20 feet of rope, as we discussed earlier. Then, tie another long piece of rope around the handle area, holding the handle together and giving you something to pull the plywood up with. The person on the bottom would load the sheets onto the rails and loop the rope around the corners, allowing the person at the top to pull the sheets up.

Be careful while doing this so you don’t lose your center of gravity and pitch over, falling off the roof. When working on the roof, precautions should always be taken using appropriate personal protection equipment to help prevent accidents.