One of the advantages of working with plywood is also one of its chief problems. That is, the size of the sheet. Transporting a 4-foot by 8-foot sheet of heavy plywood, whether that means bringing it home from the lumberyard or carrying it up a flight of stairs is always a challenge. Care and planning must be taken, to avoid the potential for injury, damage, and accidents.

The easiest way to transport plywood is to load it onto a pickup truck or trailer. Of course, that requires either owning one of those conveyances or having a friend who does and is willing to help you out. But what if you have no truck, no friends with trucks, and no desire to shell out the cash to rent a truck or have the lumber yard deliver the plywood for you? That’s where things get challenging. Nevertheless, it’s safe to say that you can move plywood around, even without owning a pickup truck.

Let me say that it has been years since I’ve owned a pickup. It’s not that I don’t want to own one, it just hasn’t worked out. So I’ve made do with what I have. Mostly that means using a small car for hauling plywood and other building materials.

The Small Car and a Trailer

I must confess, a large part of how I manage to move around a lot of building materials with a small car is that I have a small, homemade trailer to go with it. The trailer was actually built for hauling a motorcycle and is a nominal 4’ x 8’ which really means that it’s about two inches narrower and one inch shorter than that. The one inch shorter really isn’t an issue, as there isn’t a side on the back. So the plywood can hang over the edge. My problem is in fitting the 4’ wide sheet of plywood into the not quite 4’ wide trailer.

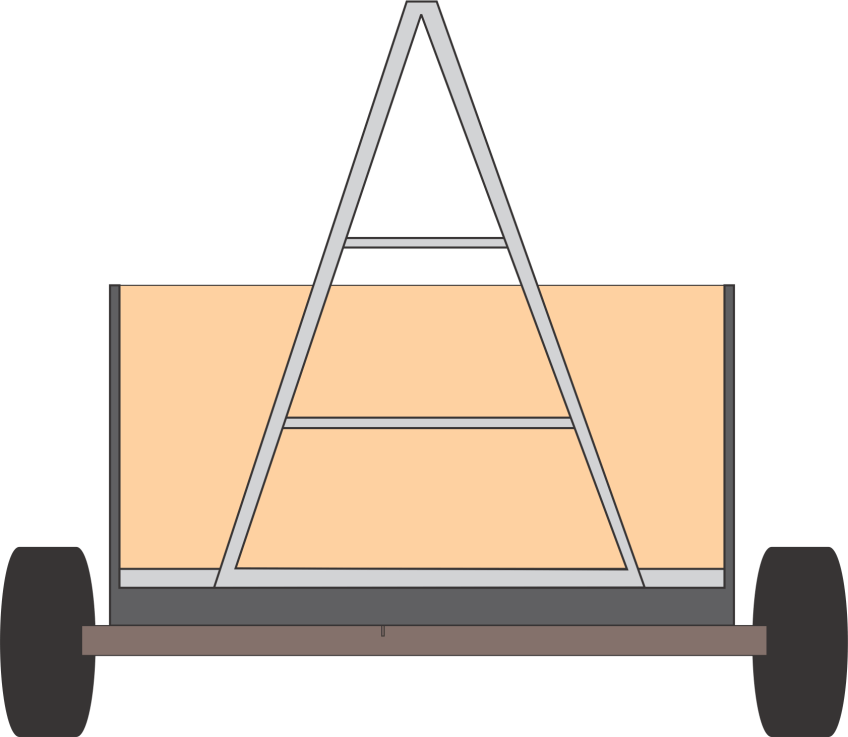

The solution to this problem is a metal rack I welded up out of 1” square steel tubing. It has a triangular cross-section, much like what you find mounted to the backs of trucks for hauling glass. I can load plywood or other sheet goods on both sides of the rack and pile dimensional lumber or other materials in the space under the rack.

The rack allows me to tie the plywood down to a sturdy structure, which will allow the sheets to stay flat, rather than twisting them, as many people do, when they don’t have enough room to make them fit. It only cost about $30 to build and locks into the existing tie-downs on the trailer.

This rack would work just as well for small pickups, which don’t have enough bed width or length to allow the sheets of plywood to lie down flat. Just be sure to have someplace where you can attach the rack to the vehicle, so it won’t slide out.

Tips for Transporting Plywood with a Small Car

Without a small trailer to use with your small car, things get trickier. Most cars today are built with a back seat that folds down, allowing you to carry long or large items. That’s great for carrying 2”x 4”s or even 2’ x 4’ project panels, but it won’t help you with a 4’x 8’ sheet of plywood. My car’s trunk is only 39” wide. Larger cars might have a wide enough trunk opening to slip a sheet of plywood into, but smaller cars won’t. About the only cars which can carry a full sheet of plywood inside, are some of the larger SUVs and full-size vans.

There is a way around this though. Most plywood projects don’t require a full sheet, in one solid piece. So why not take advantage of the lumberyard’s panel saw and ask them to cut your sheet into strips the size you need for your project. If you’re making shelves, having them cut the sheet into four 12” wide strips would be perfect. Even if you’re making a table, it’s unlikely that you’ll need a piece wider than 3’ wide, even that cut would make it fit into the trunk and through the hole made by folding the back seats down.

You always want to be careful about tying your plywood and/or dimensional lumber down, when carrying in this way. The surface of the wood is slick and it will tend to slide back when you accelerate and forward when you stop. Better to have it tied down firmly, so it can’t move. Bungee cords are ideal for this, as they can tie the wood down, while having the flexibility to allow for shifting cargo, without coming loose.

In addition, you need to tie down your trunk lid, so that it doesn’t bang up and down, damaging the surface of your plywood. The easiest way to do this is also with a bungee cord, hooking it to the trunk latch and then to the car’s bumper or understructure. If you have a trailer hitch, that’s easy to attach it to.

Keep in mind that you will have some portion of the plywood sticking out of the back of your trunk. According to the department of transportation, that’s okay, as long as it doesn’t stick out more than four feet. If it is more than four feet, it has to have a flag on it. But I would put a flag on it if it’s sticking out more than two feet, as the police cruiser following you may not have a tape measure available to check it. Better to avoid the stop, rather than put up with the hassle.

Tips for Transporting Plywood On a Roof Rack

If your vehicle has a roof rack, you have an advantage for hauling plywood, even if the rack isn’t large enough to accommodate sheets of 4×8 plywood. The rack gives you something to tie the plywood to, so all you need is a way of properly supporting it.

Before using your roof rack to transport plywood, check to ensure that it can handle the weight, keeping in mind that a sheet of ¾ inch plywood weighs close to 100 pounds. If it’s not that strong, don’t attempt it. Even if you don’t have an accident, there’s a good chance that you will cause damage to your roof, permanently denting it. Driving with an unsafe load can lead to a serious accident, or at a minimum end up with you being slapped with a misdemeanor and being forced to pay a hefty fine. Never overload a roof rack, as this can create an unsafe driving condition, affecting the vehicle’s balance.

Once you’ve determined that your car’s roof rack is suitable, move forward with the following steps.

- Place two 8-foot long 2”× 4” pieces of dimensional lumber on the roof rack lengthwise. There should be a 3 to 3 ½-foot span between the 2”x 4”s.

- Secure the 2”× 4”s to the roof rack by tying it to the front and rear crossbeams. As an alternative to tying, you could attach these with duct tape. That will help keep the 2”x 4” supports from sliding.

- Bring two additional 2”× 4” pieces along. You’re going to be using them to stabilize the top of your load.

- Buy your plywood and carefully load it up onto the first set of 2x4s. Have a friend or a worker in the lumberyard help you if possible. This will save your back and protect your car’s paint job.

- Position the additional 2”x 4”s on top of the plywood.

- Use sturdy webbed ratcheting straps, around the entire bundle, to secure all the wood to the roof rack, wrapping them crosswise to the vehicle. If your roof rack doesn’t allow you to pass the straps through them, place the straps around the wood bundle and pass through the car’s interior via the windows or doors. Position the buckles on top so they won’t ding your paint.

- Position another ratchet straps lengthwise, under the rack and around the wood bundle. Do not skip this step. This strap is to prevent the wood from sliding forwards or backwards, off the roof rack, should you have to stop suddenly or get in an accident. Even in a low-speed accident, the wood bundle becomes detached and becomes a deadly projectile.

- Drive carefully, preferably taking side streets with speed limits under 55 miles per hour.

Not Up to Transporting Plywood On a Roof Rack? Options to Consider

Do not push your luck. If your car’s roof rack isn’t rated to carry plywood and you can’t fit the load inside your vehicle, consider the following options. They’re inexpensive, especially compared to having your car get damaged, and at the end of the day, they’ll save you undue stress.

- Do you need the plywood to be intact when you get it home? Many lumberyards will happily cut it down into smaller, more manageable pieces that you can load right into your car.

- Rent a small truck or moving van. “Local moves” are usually cheap – around $20/day plus a small fee per mile.

- Rent a 4×8 trailer and tow it behind your car. Companies that rent trucks and trailers can easily set your car up for towing small loads.

- See if the lumberyard will do a local delivery for a fee. Fees can vary; but some will do so for a low price. If you’re buying a lot of materials, you may even get free delivery.

- See about hiring a handyman to carry the load for you in his truck, or offer to pay a neighbor to carry it for you.

If you’re still on the fence, consider the following points:

- If you don’t have the appropriate tiedowns, you will need to buy them.

- If you are in an accident caused by an unsafe load, your insurance company might not cover the costs. Your rates will certainly go up in the future.

- If your load causes an accident, you will be at fault, even if you thought you tied the plywood down properly.

- A gust of wind can easily rip plywood off a roof rack. There are documented examples of this occurring, and in at least one case, the plywood killed a passenger riding in a vehicle behind the one with the unsafe load.

- You’re going to spend a lot of time, energy, and worry tying the plywood to the top of the car. You are also going to have to spend time, energy, and worry driving with the load on top of your car.

- Finally, though you’ll be relieved that you made it home in one piece, you will spend time untying the plywood and getting it off your car without causing damage.

- Even if you tie everything down securely, there’s a chance your car could be damaged.

Moving Plywood around Your Shop

It can be difficult to carry a sheet of plywood by yourself, especially if you’re trying to lug around 3/4” sheets. At 60 pounds or more per sheet, it’s no wonder that it can be a bit hard to hang onto. But that problem can be quickly solved with the use of a 12 foot long piece of rope.

All you need to do is tie a loop onto each end of 12’ your piece of rope. A bowline knot works well for this, but you can use whatever knot suits you, just as long as the loop won’t close up on you. Then, when you need to carry a sheet of plywood, slip the two loops over the bottom corners of the plywood. Stand up, grasp your rope handle like you’re picking up an oversized suitcase and lift. You’ve got much better control and you’ll find that you won’t tire as quickly.

You can improve upon this slightly if you have an old piece of garden hose around. Simply cut a section of the hose and slip the rope through it, before tying the loop at one end. Center the hose and tie a square not in the rope on either side of it, just to hold it in place. That gives you a wider handle, which will be easier on your hands.