One of the key elements of any kitchen is cabinet space. Lack of sufficient cabinet space makes it difficult to store everything we find in most modern kitchens. Kitchens become disorganized and the countertops cluttered when there isn’t enough cabinet space to store everything. Architects and kitchen designers are constantly working to make the most of the space they have to work with, especially in mid-range homes where there’s a desire for quality, but might not be sufficient floor space to fit everything in.

In an effort to best use the available space, almost all kitchen designs end up including the use of at least one corner, sometimes more. This requires the installation of corner base and wall cabinets. While those cabinets have been historically inefficient, modern designs have gone a long way towards redeeming that valuable space and transforming it into prime storage space.

There are three basic styles of corner wall cabinets:

- Blind Corner Wall cabinet – This is the “old way” of dealing with a corner, where access into the corner area is through one of the wall cabinets abutting the corner. While this makes it difficult to see what is stored in the blind corner and gain access to it, the space is still usable. This style of cabinet only requires the cabinet depth along the wall with the blind side, usually 12”, but a minimum of 24” on the other wall to allow space for the door.

- Square Corner Wall Cabinet – This style of corner cabinet is “L” shaped, allowing full access to the interior via a hinged two-panel door. It requires 24” of wall space along each of the walls. The door can either be installed for left-hand or right-hand opening. If the kitchen design calls for two corner cabinets along the same wall, then the door handles will typically be installed opposite each other for symmetry.

- Diagonal Corner Wall Cabinet – This cabinet style differs from the square corner wall cabinet in that the face of the cabinet is set at a 45 degree angle, with a single door replacing the two-panel door. It provides a bit more cabinet space, but at the cost of the cabinet being so deep that some people have trouble reaching the back of the cabinet. For some people the diagonal corner may make it more difficult to use the countertop space in the corner, as the wall cabinet sticks out farther. This design usually requires 24” of wall space on both walls, although they can be manufactured slightly larger, requiring 27” of space along both walls.

These corner wall cabinets are available from pretty much any cabinet manufacturer, including Ikea. There are also corner cabinets which are similar in design to the diagonal corner wall cabinet, but larger, extending down into the area taken up by the corner base cabinet as well. They require more room to install, as the diagonal surface is larger than it is for the diagonal corner wall cabinet.

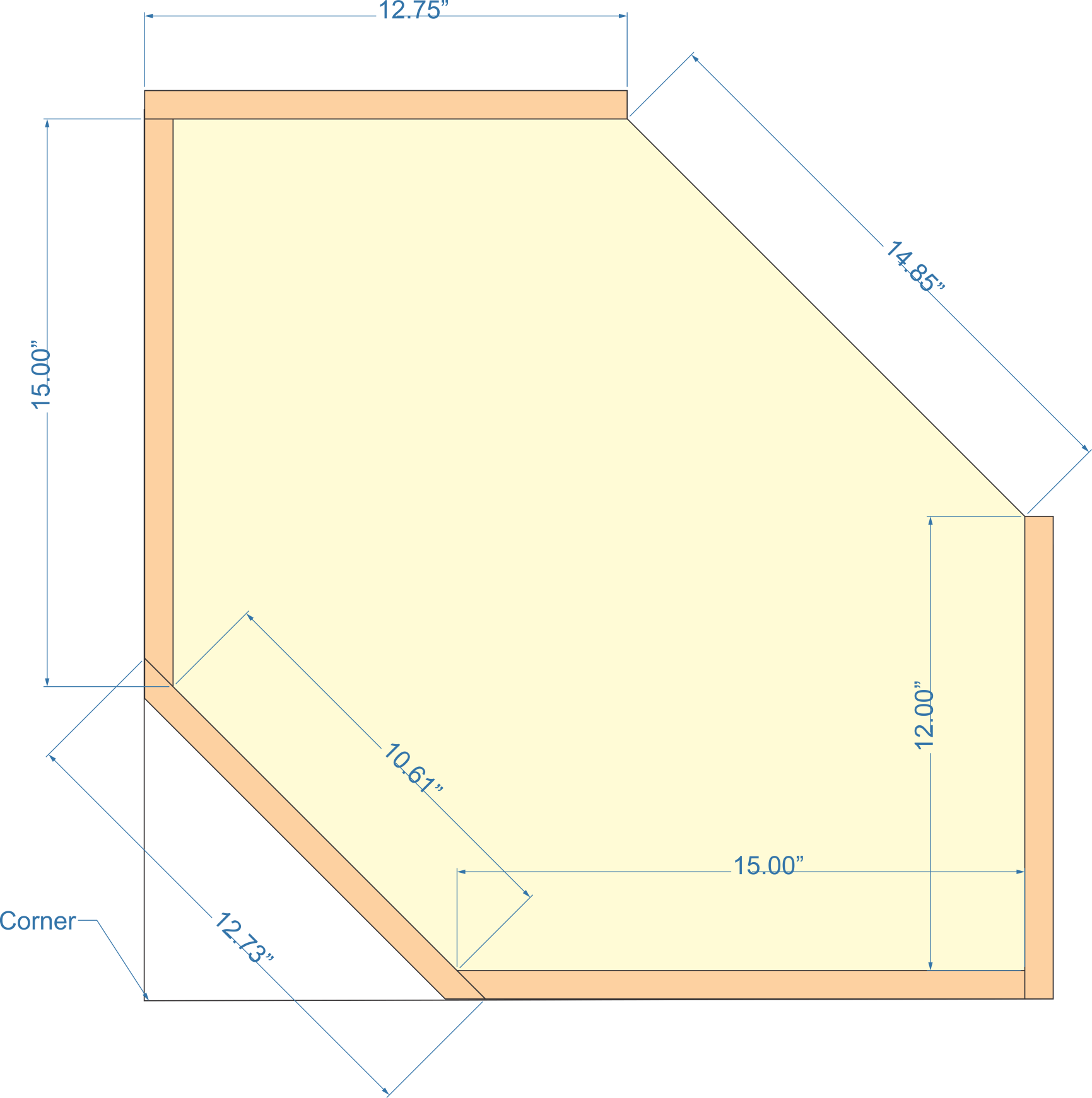

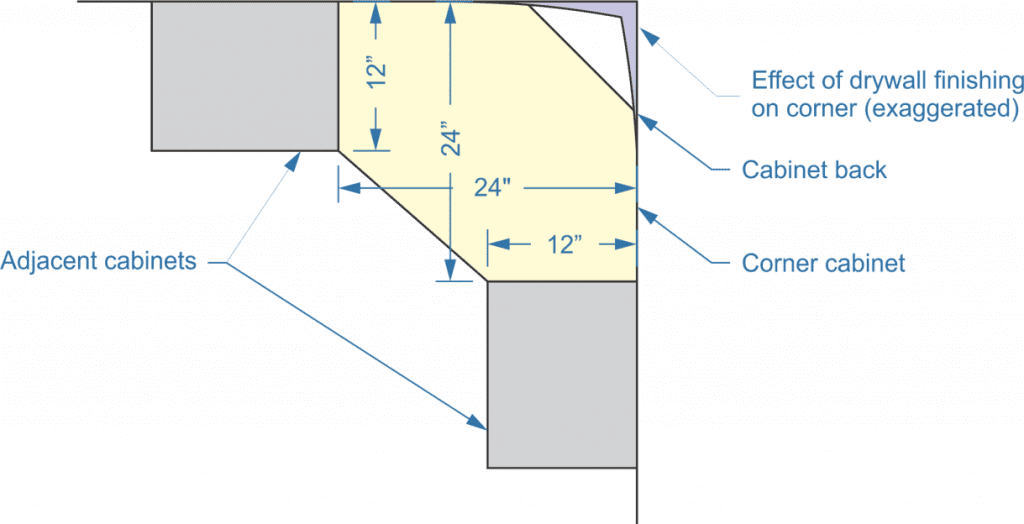

In the case of either the square corner or diagonal corner wall cabinets, the back corner, which is up against the corner of the room, is usually cut off a few inches. This prevents problems with fitting the cabinet all the way into the corner, as drywall finish usually causes the actual corner angle to be slightly obtuse, even if the walls are perfectly perpendicular to each other.

These two cabinet styles also lend themselves well to the installation of a lazy susan, making it much easier to access the contents of the cabinet. While it is possible to retrofit a lazy susan into a cabinet, it is better to order the cabinet with the lazy susan installed. It is much easier to make this installation during the process of building the cabinet, before it is hung and this saves on the cost of installing shelves, which will be removed.

Standard kitchen wall cabinet height is 36”, although they can be ordered 30” tall or 42” tall. The 30” tall cabinets are used in kitchens where there is an 8’ ceiling height and a soffit is installed, a style that used to be commonplace, but is no longer used. In kitchens with a 42” ceiling height, 42” cabinets can be used. However, 42” tall cabinets, run all the way up to the ceiling in a kitchen with 8’ ceiling height tends to make the cabinets look “top heavy,” giving the illusion that they are going to fall off the wall. Shorter standard cabinet heights are also available, for use above the stove vent hood and refrigerator.

Measuring for Corner Wall Cabinets

It might seem that measuring for corner wall cabinets is the same as measuring for any other cabinets, but there are a couple of things that we need to be careful of, especially when measuring for new cabinets to fit with existing cabinets.

- Check the cabinet depth. While standard wall cabinet depth is 30”, it is possible that the existing cabinets may not be that deep, especially if they were custom made or made by the previous homeowner.

- As mentioned earlier, the corner where the walls meet might be more than 90 degrees, even though the walls themselves are perfectly perpendicular to each other. That happens because of taping and finish the wall. As much as ¼” of drywall mud might be on those walls at the corner. Therefore, always measure the width of the cabinet at the front, not the back.

- Measure the diagonal distance between the front corners of the existing cabinets. This can both serve as a check on the cabinet width measurements and show whether a spacer will be required.

DIY Corner Wall Cabinets

While corner wall cabinets are readily available from a wide variety of manufacturers, these are one of the more complex and therefore more expensive cabinet designs there is. Replacing a full set of kitchen cabinets as part of a kitchen remodel can be an expensive undertaking. A considerable amount of money can be saved by making a set of DIY kitchen cabinets, including the corner wall cabinet.

Typically cabinets are made from hardwood plywood; however, if the cabinets are to be painted, Baltic birch is a good choice. It is less costly than other types of hardwood plywood and there are no voids in the core. The vast majority of the cabinet is made from ¾” thick plywood, but the back panel is often made of ¼” thick to save money. However, in the case of corner cabinets, thinner stock doesn’t work. The face frame of the cabinet can either be made of hardwood plywood to save money or from solid hardwood.

One important assembly note is that the visible side of this cabinet will be the inside, with the exception of the face frame and the door. So when measuring and cutting the plywood for the cabinet, the higher grade side of the plywood should be used for the interior of the cabinet.

The most complex part of any cabinet is making the doors, partially because it requires a shaper to do flat panel or raised panel doors. Few of us have that tool in our workshops, as it is a rather expensive, commercial tool. Nevertheless, some do-it-yourselfers still choose to make their own doors, while most buy doors from one of the companies which supply cabinet doors for remodeling.

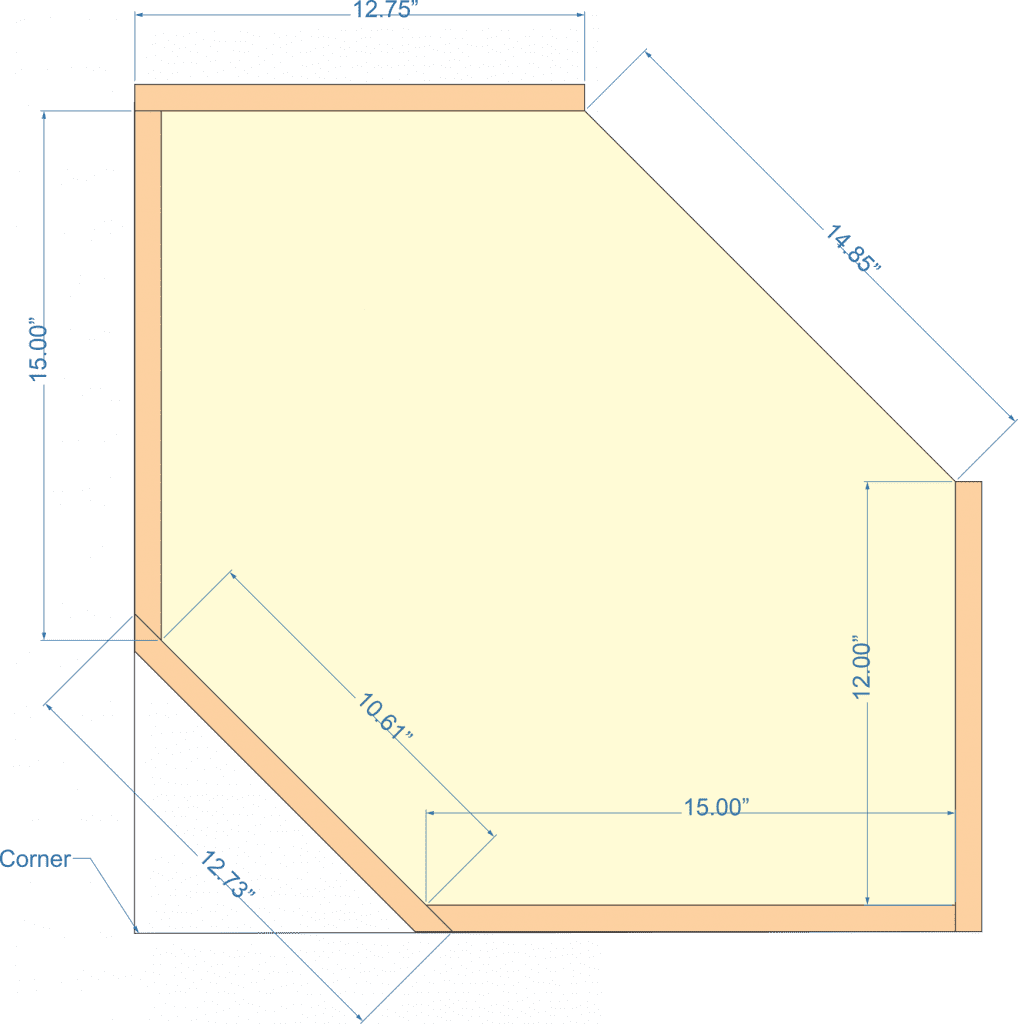

Making the Corner Wall Cabinet Case

The case for the corner wall cabinet is actually six sided, although one side is the cabinet facing. It is literally built around the shelves, so a good starting point is to cut out the shelves. Either three or four shelves will be needed for the cabinet, depending on whether one or two shelves are desired on the inside, in addition to the bottom shelf. The final shelf is actually the top. Dimensions for the shelves are provided in the drawing below, for a standard-sized corner wall cabinet that is 24” x 24”. Any angles in the drawing which are not 90 degrees are 45 degrees.

To assemble the outside of the casing, it’s best to cut and assemble two “L”s, each of which consists of one back piece which goes against the wall and one of the end pieces that butts up against the adjacent cabinets. These should be glued and nailed together, using 1-1/2” brads. Take care not to allow the brads to come through the side of the plywood, as it is very hard to patch and hide that when it happens. The diagram below can be used for the dimensions of these parts, assuming that the cabinet is 24” x 24” x 36” tall. It may be necessary to adjust the dimensions if the cabinet is going to be a different size.

Notice that the diagonal piece that goes in the corner overlaps the two back pieces. This is important for assembly, as the two “L”s will be attached to the shelves first. Once attached, it would be more or less impossible to attach this piece, if it were cut to overlap the back pieces from the inside.

Three of the pieces have to be cut at a 45 degree angle, the two back pieces and the diagonal piece across the corner. Whenever cutting panels at an angle, there’s a high chance of the dimensions being slightly off. So it would actually be a good idea to make the first cut for these panels slightly oversized, and then trim them down to the actual size. Determine that actual size by comparing them to the shelves, not necessarily to the dimensions, as they have to fit the shelves no matter what.

With the shelves cut and the glue on the two “L”s dry, assembly of the cabinet can begin. It’s a good idea to lightly sand all the surfaces which will be on the inside of the cabinet, before assembly. While the plywood will come from the mill sanded, it’s a good idea to sand it lightly again, with fine sandpaper, just to remove any marks that might be on the surface. Don’t oversand or use a coarse grit sandpaper, as it is very easy to go through the thin face veneer.

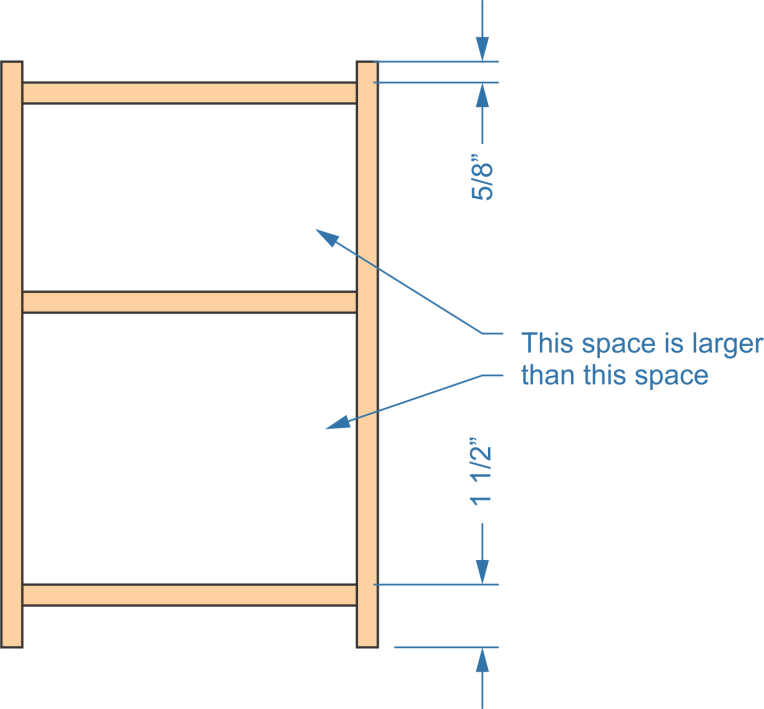

The top and bottom shelves need to be installed before any others, as this will help in establishing and holding the dimensions of the cabinet. The top shelf should be located 5/8” below the top edge of the sides and back and the bottom shelf should be located 1-1/2” above the bottom edge. The recess in the top is so that the top shelf is not visible while standing in front of the cabinet, when it is mounted. The recess in the bottom is to align the top of the shelf with the bottom of the cabinet facing.

Glue and nail the top and bottom shelves to one of the “L”s with 1-1/2” brads, nailing through the side and back panels. These nail hole will not be visible when the cabinet is installed, as they will be covered either by adjacent cabinets on either side or by the wall. It’s a good idea to scribe a line where the nails need to go, so as to avoid the problem of missing the shelf and putting a nail into the air. Don’t depend on nailing “by eye,” as nobody’s eye is that good. Nailing by eye is a sure way of missing the edge of the shelf when nailing.

With the top and bottom shelves installed, the middle shelf or shelves can be placed inside of the cabinet and installed as well. If only one shelf is to be installed, it should be installed above center, leaving roughly 2/3 of the height for the bottom shelf. If two shelves are being installed, they should be spaced evenly, making three spaces of equal height.

Once all the shelves are attached to one of the “L”s, they can be attached to the other. The tricky part here is getting the spacing the same, so that none of the shelves end up sitting at an angle. Take careful measurements for the shelf height and nail lines from the first side installed and transfer those to the other “L” so that the two end up attached equally to the shelves.

The final part of assembling the cabinet is to install the diagonal piece across the back, ensuring that it doesn’t overlap the edge of either back piece. Any overlap will make the cabinet stick out from the wall when it is being mounted. It’s actually better to have this piece cut a slight bit narrow, so as to prevent it from causing problems when installing the cabinet. However, don’t cut it too narrow, as it is necessary to nail through the edges of it, into the two back pieces, to hold the panel in place.

Making the Face Frame for the Corner Cabinet

Making a face frame for any cabinet is extremely simple, especially a wall cabinet. All it is, is a rectangular frame, made of S4S hardwood 1”x 2”s. The only tricky part is building the frame without any visible fasteners. There are four ways of going about this:

- Blind mortise & tenon – This is the classic way of making cabinet facings, but also the hardest to accomplish. What makes it a “blind mortise” is that it doesn’t come out the other side. So anyone looking at the joint will only see butt-jointed boards. This requires the skill to cut a mortise cleanly, without access to the other side. While that can be done by a novice woodworker, it is challenging.

- Doweling – Doweling is essentially a simpler form of mortise & tenon, with dowels (usually 2) taking the place of the tenon and allowing a simple drilled hole to take the place of the mortise. The only potential difficulty with this method is aligning the holes properly; but that problem can be solved by using one of the various doweling jigs available on the market.

- Biscuits or Dominoes – biscuit joiners were developed to make the idea of doweling even easier, cutting a slot that an oval pressed wood wafer sits into. Domino joiners take that to the next level, using a rectangle of wood with rounded corners. Both work well, although the domino gives more positive contact and position alignment. Some woodworkers don’t like these, stating that they aren’t necessary for laminating tabletops, as the glue joint is stronger than the wood itself. But in this case, they make a considerably stronger joint than just gluing the wood together.

- Pocket screw – One of the more recent additions to wood joinery is the pocket screw. This system, which requires a jig, allows an angled screw hole to be made in the back side of the boards, which the screw is then inserted into. It is designed specifically for joints like this. Although the holes are visible, they are only visible on the inside of the cabinet.

One of the keys to making any sort of furniture or cabinets is hiding the end grain of the various pieces. This is more or less impossible on the face frame of a cabinet, unless the corners are mitered. However, that’s not the normal way cabinet facings are made. Rather, the vertical stiles overlap the horizontal rails, so the only way that end grain can be seen is if someone is looking down from above the cabinets or looking up from below them. Neither of those is likely to occur, unless someone is getting into awkward positions to check out the construction of the cabinet.

The face frame is primarily glued to the face of the cabinet, with only enough brads to help hold it together while the glue is drying. Using a lot of brads makes more hole that have to be filled, while using only a few and hiding those in the grain as best possible, can make it so that once puttied, they are invisible.

As noted above, the face frame has a 5/8” reveal at the top and a 23/32” reveal on the bottom. The sides of the face frame should also have a reveal of ¼”.

Hanging a Corner Wall Cabinet

Before hanging the wall cabinet, locate the studs in the wall, measuring how far they are from the corner. screw used in hanging the cabinet need to go through the drywall into those studs. The drywall itself isn’t strong enough to support the weight of the cabinet. Mark a line on the wall for aligning the bottom of all the cabinets.

Typically corner cabinets are installed first, although that isn’t a hard and fast rule. However, by installing the corner cabinet first, any slight horizontal adjustment in the cabinets can be made at the opposite, open end.

Transfer those dimensions to the inside of the cabinet. In cases where ¼” thick plywood is used, the cabinets need to be built with a hanger strip across the top and bottom of the cabinet. In those cases, the hole for the hanger screw must go through the strips, as the ¼” plywood is not strong enough to support the weight of the cabinet. However, we built this cabinet with ¾” thick plywood all the way around, so the screws can go right through the back of the cabinet. drill holes approximately 4” from the top and bottom of the cabinet, through the back, so that the holes line up with where the studs will be. That should make for a total of at least four screws. Then insert screws far enough into the holes so that they will not fall out, but not so far that they stick out the back side.

lift the cabinet into place with a helper and hold it while starting the screw into the studs, but don’t drive the screws all the way in. Before driving the screws all the way in, check the vertical location of the cabinet and that it is plumb. If it is not, pull the screws out and make any necessary adjustments.

It may be necessary to use shims behind the cabinet, in places where the wall is uneven. In that case, the shim needs to be inserted far enough behind the cabinet that the screw can go through the shim as well, holding it in place. Once everything is properly aligned, tighten down the screws and then cut off the shims flush with the edges of the cabinet.

In cases where there is no cabinet to be installed alongside the corner cabinet, it is typical to install a panel on the side of the cabinet, behind the frame, to bring the side of the cabinet flush to the frame. There may also be cases in which there is a need to install a spacer between the corner cabinet and an adjacent cabinet, due to the set of cabinets not fully filling the space given for them. However, since these are custom-made cabinets we are talking about, it would be better to make a wall unit wider, rather than a standard size, so that the extra space is usable for storage.