One of the challenges in using plywood as a material for projects is fastening the plywood. While glues, screws, and nails (the traditional fasteners) work, many newer pins and materials developed for the furniture assembly industry are considerably better.

The only problem is that they tend to be expensive materials if you’re not a furniture manufacturer.

One of the features of many of these newer hardware fasteners is the ability to remove bolts and install them, taking the bolt assembly apart for moving or modifications. While not every hardware project has that need, it is an excellent option to have available when needed.

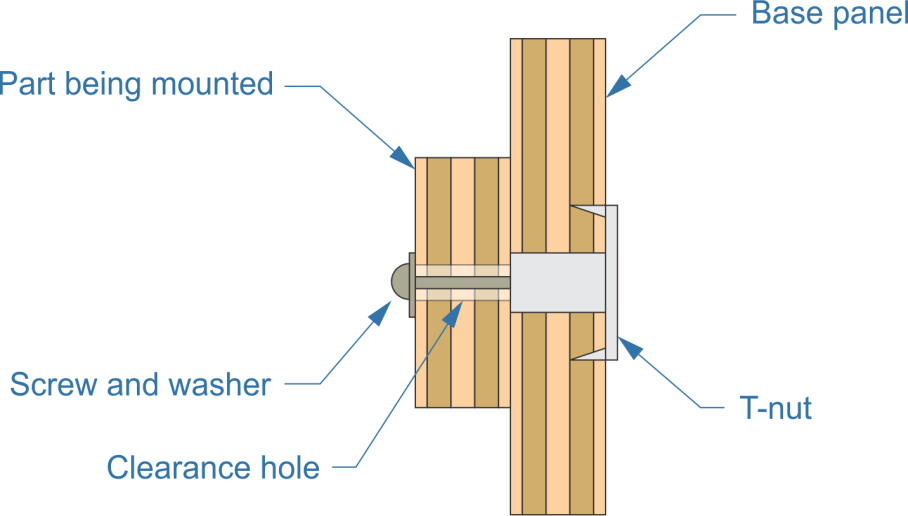

Another fastener option, which has been around much longer and is considerably less expensive, is T-nuts threaded inserts. These threaded inserts are a type of threaded insert specifically designed for use with plywood products, especially those which do not have a good wood grain for other threaded insert inserts or fasteners for the threaded insert to mount securely into.

Threaded inserts vs. T nut

What makes T-Nuts different from these other threaded inserts is the clamping force provided by fasteners running into the material in the nut in place. Literally, the tighter the screw, the more solidly the line of the T-nut threaded insert is pulled and secured in place, as the head of the thread of the tightening T-nut will draw on the opposite side of the sheet of plywood.

This makes tee nuts and the T-nut an ideal fastener for many plywood projects. They are easy to install, and as long as tee nuts are installed correctly, there is very little chance of them falling out without someone driving or screwing them out. The clamping force of a screw eliminates that little chance tightened up in the T-nut.

Installing T-nut

Since the only way the T-nut can come out of the wood is to be pulled through it, it is a solid fastener to install. T-Nuts installed into soft plywood have a pull-out strength of 1378 pounds, while those seated in hardwood plywood have a pull-out strength of 1850 pounds. When used with other plywood products, such as MDF and OSB, these numbers will be lower because of the lower power of the materials the T-nuts are installed into.

In many cases, the limiting factor in the strength of the T-nut isn’t the nut itself or even the wood; the internal threads of the screw are driven into the T-nuts. A ¼” diameter #2-grade screw has internal lines and a shear strength of 260 lbs.

While a #6 screw only has internal threads and a shear strength of 72 lb srength is the amount of force that has to be applied across the axis of the screw to cause failure, usually breaking or at least deforming).

Even so, it should be noted that it is not hard to knock and insert a T-nut wrench out of the wrench socket in the bolt hole it is mounted in if one drives it out with a stick or inserts a punch from the wrench socket or screw side.

Installing T-Nuts

Because of the shear strength of tee and t nuts, T-nut sizes should be selected based on the load that will be put on the tee or t nuts provided and the screw running into them. When in doubt, go more extensive, giving more safety margin, especially when critical loads are mounted on the T-Nuts provided or the attachment will support a person’s weight.

T-nuts are extremely easy to install. To start with, it’s a good idea to drill the pilot hole through both the object to be mounted to the plywood panel and the panel at the same time, clamp the pieces together so that they can’t slide while drilling the tee, and install t nuts in plywood. If the work to be mounted already has holes. Use it as a template to make a tee and install t nuts in plywood to provide and mark the panel it will be mounted to.

The hole in the piece to be mounted to install t nuts is pre-drilled, and the panel that the T-nut will be installed in will need to be enlarged slightly to allow clearance for the machine screw and T-nuts that will be used for installing the device or part to be threaded rod and mounted pre-drilled hole. Hole sizes can be determined by holding up the screws and T-nuts to the drill bits, but standard hole clearances for common thread part sizes are:

Screw sizeDiameterScrew Clearance HoleT-Nut Clearance Hole#6-320.138”11/64”11/64”#8-320.164”13/64”7/32”#10-240.190”7/32”1/4”1/4-200.250”9/32”5/16”5/16-180.313”11/32”3/8”3/8-160.375”13/32”29/64”

The T-nut is installed from the back of the other side of the panel inserts, placing the barrel of the threaded T-nut into the hole drilled for it. The plywood panel inserts should be laid on a solid surface or floor for this installation. Once the barrel of the threaded T-nut is in place, its flange should be pulled and hit with a hammer to drive the prongs into the back of the panel inserts until the bottom side of the barrel with the flange is flush with the back of the other side of the panel inserts.

T-nuts should not fall out if properly installed. However, the thread or the threads of thread in the nut can twist while being installed. Should this happen, the line or the threads of yarn in the prongs could bend and slide out rather than being driven into the panel. In such a case, the flange will not lay flush with the back of the panel, and the T-nut should be replaced.

Even though T-nuts are secure when installed, they will not reinstall well in the same part and drill a hole again if driven out. The prongs count on the compression factor of the wood fibers to hold them in place.

Once the T-nut has been removed, the wood fibers won’t provide as much compression. However, if the T-nut is reinstalled in the same pre-drilled hole but with the prongs twisted to drive into a fresh point in the plywood panel, they will hold well.

Installing T-nuts Blind

It is possible to encounter situations where T-nuts might need to be installed, but there is no way of hitting the back side of the T-nut with a hammer. This is called a “blind installation.” It is still possible to install T-nuts in this manner. There are two ways of doing so.

The faster but not as effective way to install, tighten and install, tighten and install it is to use a pair of channel locks, clamp the panel and insert the head of the clamp into the threaded T-nut to apply pressure to press the prongs into the backside of the wood.

This works fine for MDF but does not work so well with OSB or plywood. It is easy to bend points using a wrench with this method of tightening and installation.

The slower, more secure way of installing them blindly is to place a wrench, insert the threaded rod nut or T-nut into the back of the hole, and draw it in with a screw. A couple of ashes should be placed under the screw head for this assembly, and a lot of torque will need to be applied.

It would be better to use a hex-headed screw so that a ratchet could apply leverage. Care must be taken to ensure that the threads on the threaded T-nut’s prongs go into the panel’s wood.

Using T-Nuts to Make a Rock Climbing Wall

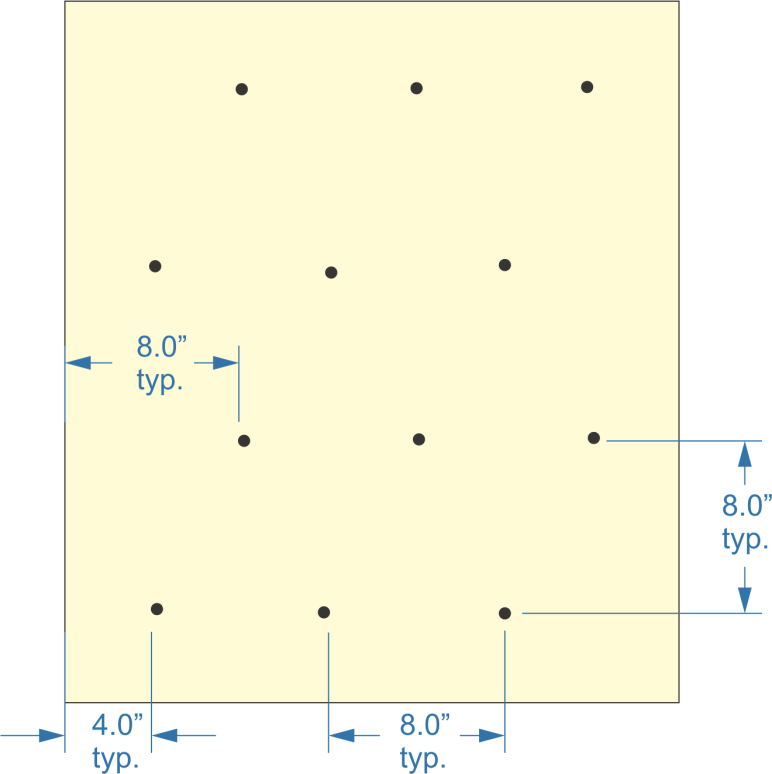

One handy place for using T-nuts is the t nuts installed in plywood in the building of a rock climbing wall. Typically, 72 T-nuts are installed in one 4’x 8′ sheet of plywood, with the T-nuts being roughly 8″ apart. This allows for many positions to mount each “rock” to, creating various challenges to overcome while climbing the wall.

A minimum size of ¼” bolts should be used for attaching holds to a climbing wall. Anything smaller doesn’t have the weight capacity to provide a good margin for safety. Larger bolts aren’t a problem.

The wall should be made of ¾” thick plywood, preferably birch or marine plywood. Avoid softwood plywood, as it has voids, and the surface may give off splinters.

Lay out a roughly diamond-shaped pattern for the bolt and insert the bolt and T-nuts, spacing the bolt rows 8″ apart and the individual bolt holes in each bolt row 8″ apart. Drive the bolt and insert the bolt and T-nuts into the panel from the back side before mounting the bolt to the panel.

It’s also a good idea to sand and finish all the panels used in the rock wall installation with varnish to protect them from splintering.

Rock wall T-nut layout

Most people buy their holds, the “rocks” used for a rock climbing wall commercially. However, there are two ways you can make your own.

Making Handholds Out of Rocks

The first is to use natural rocks, drilling clearance holes through them for the mounting bolts to slide and the screwing to go through. Before hitting the spots, clean the stones and level the back side by applying a layer of Bondo (a two-part body filling compound used in auto-body repair) thick enough to provide a flat back. Set the rock down, Bondo side down, on waxed paper for Bondo to cure.

The hole should be drilled through the rocks with a masonry drill bit and a hammer drill. Keeping the drill bit cool is necessary, as heat will cause it to dull quickly. Submerging the rocks in water while drilling them is an excellent way to protect the drill bit.

While masonry drill bits work well for rocks, they aren’t all that great for Bondo, so the final part of the drilling, through the Bondo material, may have to be done with a standard twist drill.

However, don’t try drilling through the rock with the twist power drill; it will dull the whole power drill bit.

Finally, clean up any excess Bondo material that squirted out the edges on the belt sander or grinder, grinding the Bondo material flush with the edge of the rock so that the material is not very visible.

Making Handholds Out of Plywood

Handholds can also be made of plywood or even some other scrap pieces of wood or pieces of dimensional lumber. To start, laminate three layers of ¾” thick plywood and stick them together.

Scrap pieces of wood the same sort of wood as birch plywood, or marine grade plywood, or wood used for the wall itself will work fine. Be sure to spread glue over the entire wood surface before clamping the pieces of wood together.

Once the glue dries, cut the laminated plywood into irregular shapes; triangular, crooked rectangles, trapezoids, and freeform shapes. Almost anything will do, as long as they are large enough to grab hold of and grip and use as a toe hold.

Round the edges and corners of those shapes with a belt sander or grinder, making them more irregular. The idea here isn’t symmetry, as natural rocks aren’t symmetrical. Be sure not to leave sharp edges or corners around the shape, for example, as those could cause splinters or cuts.

It is a good idea to grind a roughly ½” wide by ½” groove into the top side of each handhold or to undercut the opposite side or another side of the back edge about the same amount, to act as a grip.

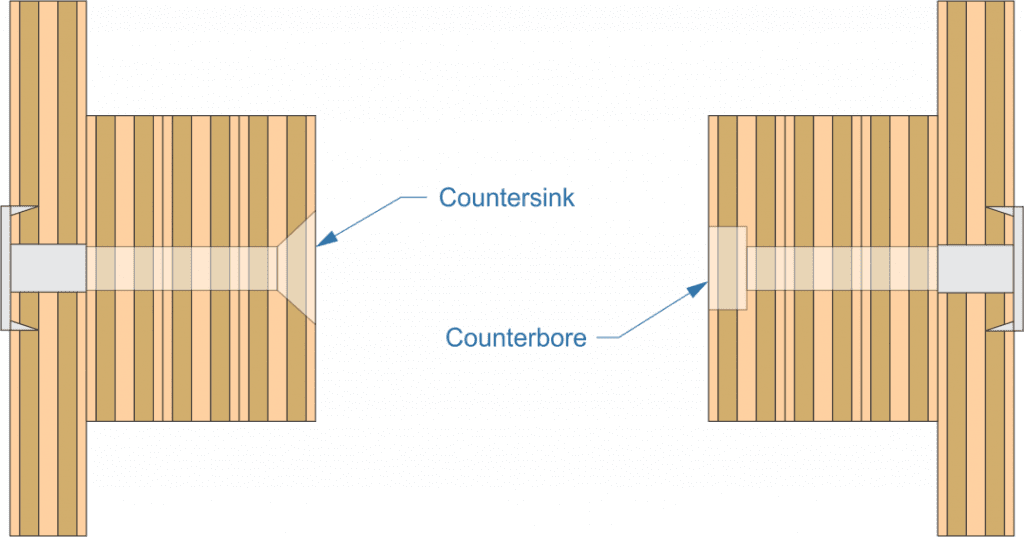

The attachment hole should be countersunk if flat head screws are used to mount the handholds to the climbing wall or counterbored if round head screws or hex head bolts are to be threaded, inserted, and utilized.

Ensure that the countersink or counterbore is deep enough so that the head of the fastener will sit below flush, eliminating any risk of the user’s hands being cut on a burr on the edge of the pilot hole or any hardware used to install the handholds.

If hex head screws or bolts are used, it is necessary to make the counterbore wide enough for the screw or bolt head and the socket that will be threaded, inserted, and used to install it.

Countersink vs. counterbore

When drilling a screw hole by inserting a countersink, it is usually easier to drill a hole for the clearance hole first and then insert the countersink, allowing the clearance hole to act as a guide for the countersink bit.

However, when drilling a counterbore, it is usually easier to drill a hole for the counterbore first and then the clearance hole. That way, the center indentation in the surface of the hole made by the counterbore provides a centering point for the drill bit used to drill the clearance hole.