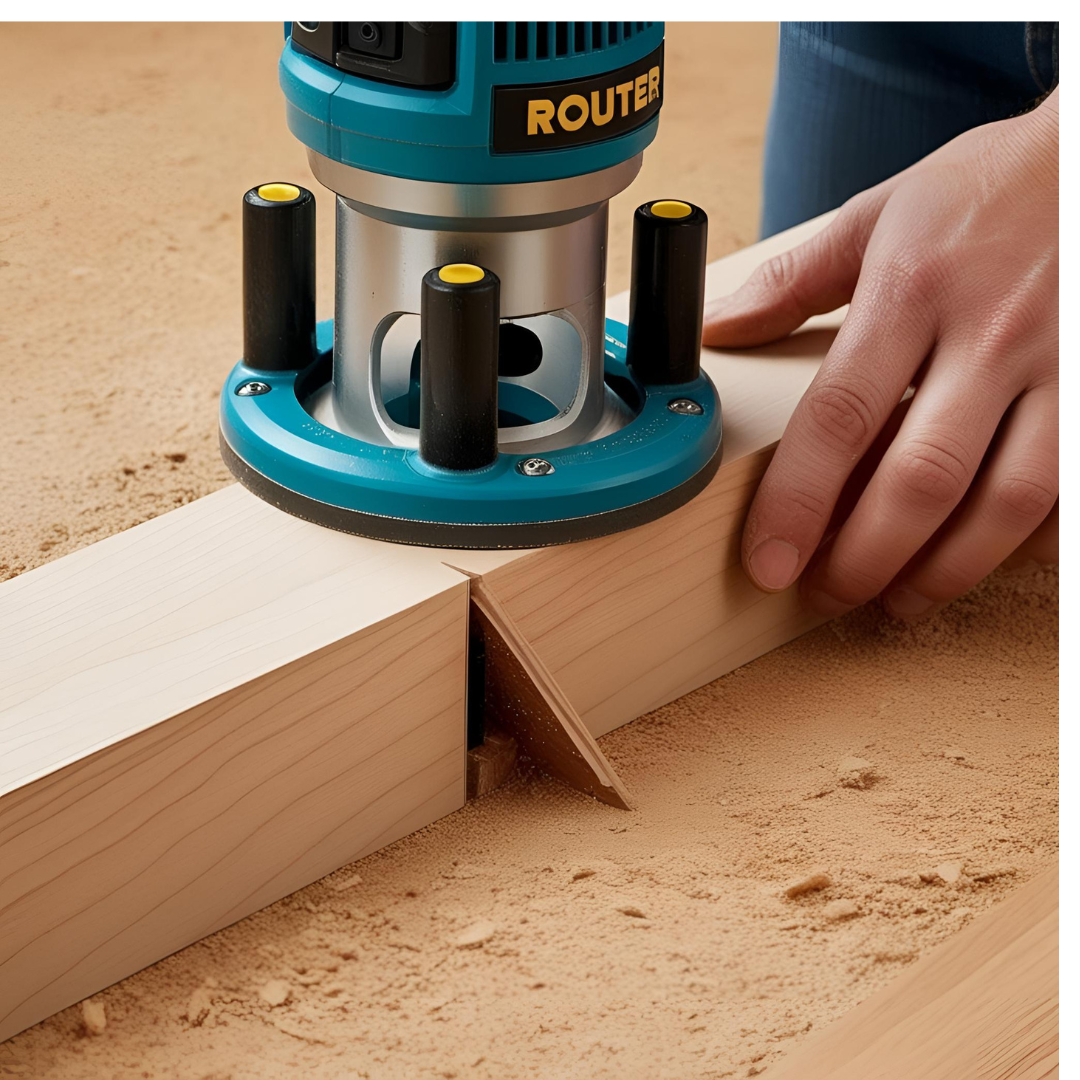

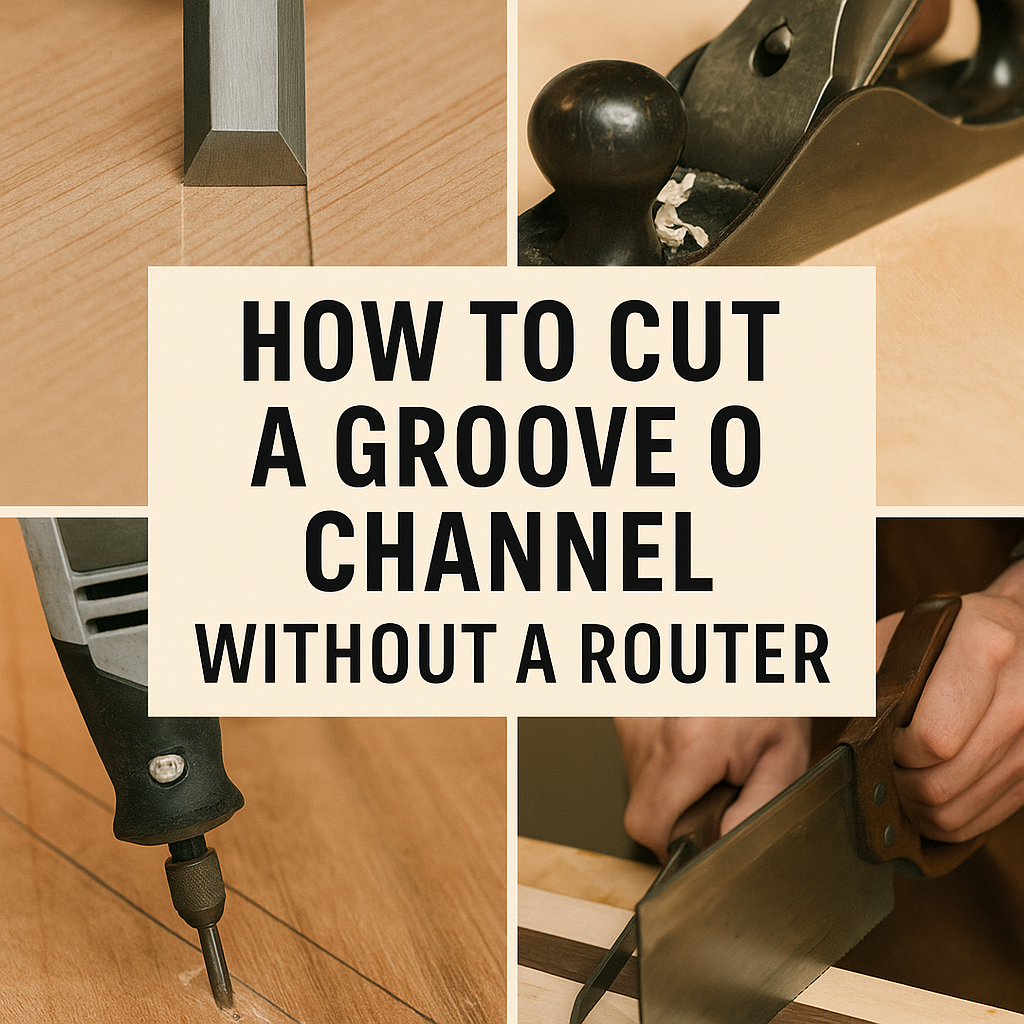

Woodworking is all about shaping wood, and one of the most essential shaping techniques is cutting grooves or channels. Whether you’re building a cabinet, installing shelves, or making joinery cuts, a router is often the go-to tool. But what if you don’t have one? In this guide, we’ll show you how to cut a groove or channel without a router, using classic techniques and affordable tools.

Why Learn to Cut Grooves Without a Router?

Routers are versatile and powerful tools, but they’re not always available, affordable, or necessary. Learning alternative methods to cut grooves helps you:

- Save money on expensive tools

- Use what you already have

- Improve your skills with hand tools

- Work in places without electricity

Knowing router-free methods also comes in handy for repairs, on-site adjustments, and small projects.

How to Cut a Groove or Channel Without a Router

Looking for the right tools? Here are some highly rated options on Amazon to help you get the job done without a router:

- Freud 6″ x 10T Stacked Dado Set – ideal for cutting grooves on a table saw.

- Stanley 16-150 3-Piece Wood Chisel Set – perfect for detailed hand-cut grooves.

- Veritas Large Shoulder Plane – for precise rabbets and edge channels.

- Dremel 4300 Rotary Tool Kit – great for short decorative grooves.

- WORKPRO 6-Inch Woodworking Vise – hold your workpiece securely.

(As an Amazon Associate, we earn from qualifying purchases. Your support helps keep this site running!)

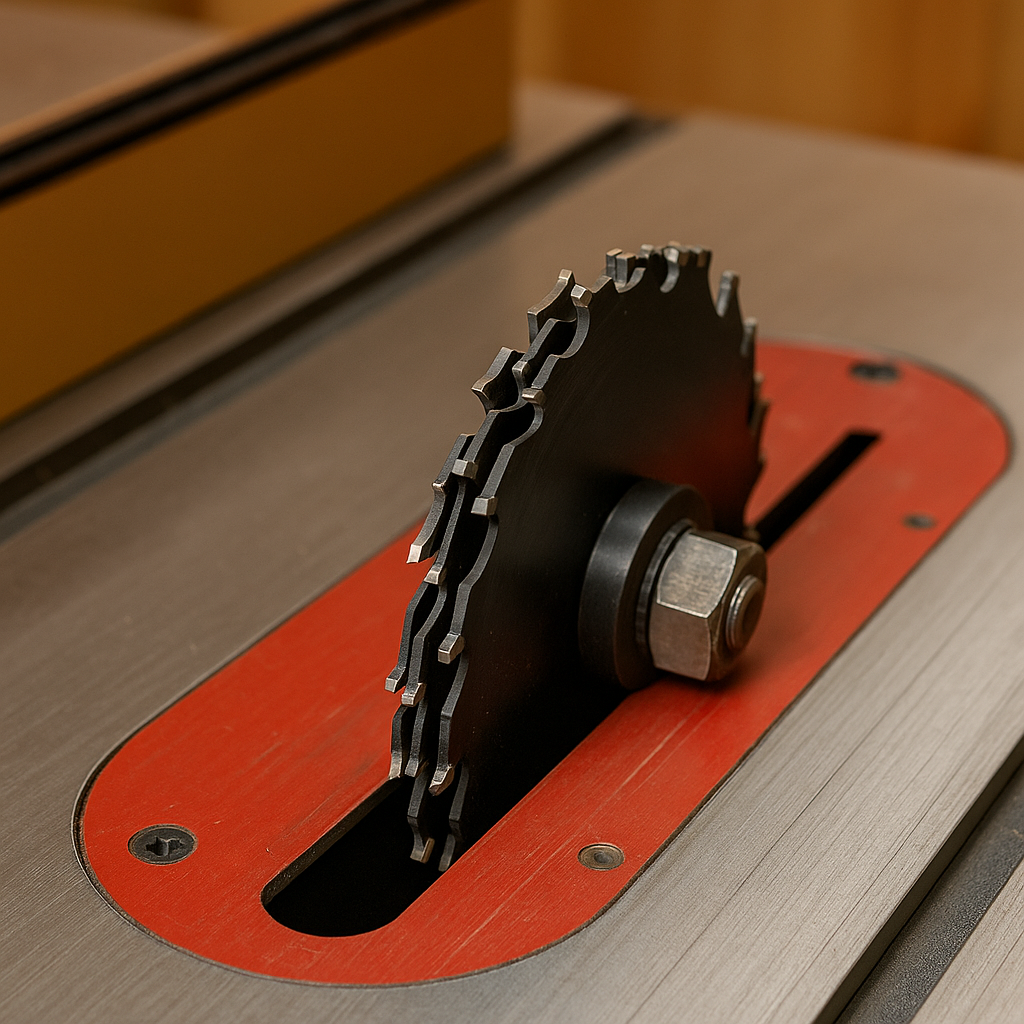

1. Table Saw with a Dado Blade

If you own a table saw, a dado blade is a fantastic way to cut clean, consistent grooves. There are two types:

- Stacked dado blade set – for precise, adjustable grooves

- Wobble dado blade – quicker setup, rougher finish

Always measure the distance from the blade to the fence and test-cut on scrap wood before cutting your actual piece.

2. Standard Table Saw Blade with Repeated Passes

If you don’t have a dado blade, you can still cut a groove using your regular blade by making multiple passes:

- Set your blade depth

- Move the fence in small increments

- Clear out the waste between cuts

This works well for grooves 1/8″ or wider.

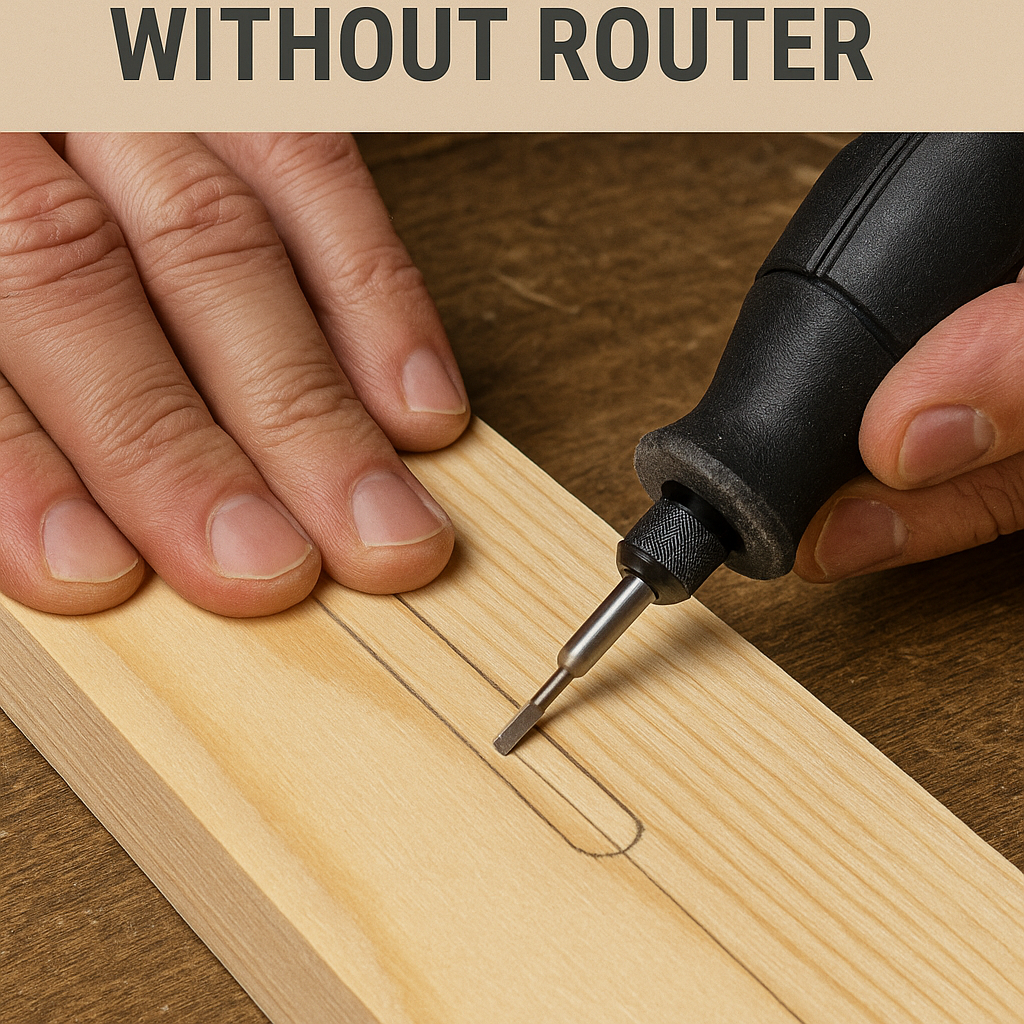

3. Chisels and a Backsaw (Classic Method)

This time-tested method involves:

- Marking your groove edges with a pencil or marking knife

- Using a backsaw to define the edges

- Removing the waste with a sharp chisel

This technique offers full control and is ideal for short grooves or custom joinery.

4. Rabbet or Shoulder Plane

These traditional hand planes are perfect for making edge grooves (rabbets). Steps:

- Score your edge line with a marking knife

- Use a fence or a clamped straightedge to guide the plane

- Work slowly and check depth frequently

This is a great way to cut clean-edge channels.

5. Dremel Tool

A Dremel rotary tool can cut short or shallow grooves:

- Pre-score with a utility knife to reduce splintering

- Choose the right bit for your groove width

- Follow your line carefully and go slowly

Dremels are great for decorative or tight areas, but not ideal for long grooves.

Cutting Slots Without a Router

Keyhole Slots

Keyhole slots are useful for wall mounting projects. You can:

- Drill a clearance hole for the screw head

- Drill a second hole for the screw shaft

- Connect the two holes with a keyhole saw or chisel

Jigsaw Slots

To cut an open slot:

- Drill holes at each end of the slot

- Use a jigsaw to connect them

- Clap your workpiece for stability

Plunge Cuts with a Circular Saw

Plunge cuts are trickier but can be done:

- Mark your cut clearly

- Raise the guard and tip in slowly

- Make sure your blade depth is accurate

Use extreme caution and practice on scrap first.

Advanced Groove Techniques for DIY Projects

Use a Fence or Straightedge

Using a clamped guide improves accuracy for chisels, circular saws, and planes. Featherboards can also help on table saws.

Grooving Plywood and Laminated Sheets

Plywood can tear out easily. To prevent this:

- Score the surface with a knife before cutting

- Use painter’s tape to reduce splintering

- Back up the workpiece with scrap wood

Fine-Tuning Depth and Width

- Use test cuts to verify fit

- Mark depths on the edge with a pencil or knife

- Use sanding blocks or files to refine the fit

Decorative Grooves and Inlays

Use scratch stocks, gouges, or Dremels for inlays:

- Shallow passes work best

- Use contrasting materials for visibility

- Tape off areas around the groove to avoid scratches

Structural Joinery Grooves

Grooves aren’t just decorative—they add strength. Examples include:

- Dado joints for shelves

- Rabbet joints for drawer backs

- Sliding dovetails for strong, invisible joints

Use saw and chisel combos or angled planes for precision.

Tips for Beginners

For more traditional woodworking tips and router-free joinery techniques, check out these helpful articles:

- Beginner Woodworking Projects You Can Build in a Weekend

- How to Use a Chisel Like a Pro

- Plywood Grades Explained

These resources will help you sharpen your skills and

- Practice on scrap wood first

- Keep your tools sharp

- Always clamp your workpiece

- Take your time—precision matters

- Invest in one tool at a time and learn it well

Final Thoughts

Learning how to cut a groove or channel without a router gives you more freedom, flexibility, and skill as a woodworker. Whether you’re working in a power-free environment or just want to challenge yourself with traditional methods, these techniques open up new possibilities for joinery, decorative detailing, and craftsmanship.

So next time your router is out of reach, grab a saw, chisel, or plane, and groove on.

Sharpening and Maintenance Tips for Router-Free Groove Tools

Your success with hand tools depends heavily on how well they’re maintained. A dull chisel or poorly set plane can ruin a piece of hardwood or tear out delicate grain. Start by learning the basics of tool sharpening. A simple sharpening system with water stones or diamond plates and a honing guide can keep your chisels and plane blades razor-sharp. For saws, invest in a small triangular file and learn to sharpen your backsaw teeth—there are countless tutorials online

. Keep your Dremel bits and jigsaw blades clean and replace them when they get dull or start to burn the wood. Maintaining a small tool care station in your shop not only improves your cuts but also extends the life of your gear. Regular honing and stropping can save time in the long run by reducing the need for frequent sharpening.

Choosing the Right Wood for Groove Cuts Without a Router

The species and grain direction of your wood can significantly impact how easy it is to cut a clean groove. For beginners, softwoods like pine or poplar are forgiving and easy to work with using hand tools. Hardwoods like oak and maple require sharper tools and more effort, but offer stronger joinery and cleaner lines. Be mindful of grain direction—cutting with the grain reduces the chances of tear-out, while cutting across it requires special care and sharp blades.

For plywood, make sure to use a fresh blade and always score the top veneer to prevent chipping. When planning a project that requires groove joinery, test your tools on a scrap of the same material before cutting into your workpiece. This will reveal how the wood reacts and how your tool setup may need to be adjusted.