Before cordless drill/drivers, before the corded electric drill, woodworkers still needed to make holes. In fact, if you go back far enough in time, you’ll find that they needed to make more holes than we do today. That’s because woodworkers held things together with fitted wood pegs, rather than doing it with screws and nails, like we do today.

The tool used for making round holes in wood in those times was the woodworking brace. This manual drill was used with different sorts of drill bits than we use today. Often referred to as “brace drills” they would be more correctly labeled “auger bits.”

But that wasn’t the only manual drill used in those times. In addition, there was the “egg beater drill,” the auger, and a small hand auger, known as the “gimlet.” Each had its own purpose and all of them would be found in the toolbox of a carpenter, cabinet maker or furniture maker. In fact, several different sizes of each would be included, especially in the kit of someone who had been doing woodworking for a number of years.

You can still buy vintage hand drills of all these types, although tool manufacturers still produce at least a representative sampling of these tools. However, the true carpenter or woodworker of the past would actually have several examples of these tools, especially the drill brace, with a variety of sizes in their kit.

Most hand drill bits are actually auger bits, which differ from standard drill bits in form and function, although both exist to create round holes. Let’s look at these various tools and their differences.

Augers & Auger Bits

The word “auger” can either refer to an entire tool or to a type of drill bit. The more common is auger bits for use in a hand brace. But what makes these brace bits so effective for woodworking is that they are auger bits. What that means is that they cut through an auger operation.

The auger operation I’m referring to is a tapered wood screw point on the drill bit. This is combined with a spade bit, to make a very effective cutting tool. The screw point draws the bit into the wood, where the spade can cut the material out, creating the hole. This combination is so effective, that modern spade bits are returning to this design, combining an auger point or screw point to spade bits, in order to make them cut through the wood faster.

When buying vintage auger bits for use with a hand brace, this screw point is critical. You can reshape and resharpen the spade bit easily with a file; but you cannot easily reform the screw point, if it has been blunted. Trying to use these bits in a hand brace drill, without the auger screw point, is extremely difficult. You would find that cutting through the wood to make a hole would go very slowly.

Of course, the advantage of buying vintage hand drill auger bits is that they are going to be cheaper than buying new ones, especially for the larger hole sizes (1/2” and above). When buying these brace drill bits, you need to make sure that they match up with the woodworking brace that you will be using them with. Some use a straight, round shank, while others are a square tapered shank. Newer auger bits might also have a hex shank, as they are designed to be used with power tools.

The Auger Tool

The auger tool is a simplified version of the bit and brace, combining an auger bit with a T-handle. Used only for larger sized holes, the auger tool allows the woodworker the ability to put their weight into the drilling operation, helping to produce holes of 1 inch or larger. Typically, a woodworker who has one of these, only does so for specific operations, such as making holes for pegged construction, and will therefore only have one size.

This tool is large enough that the workpiece is placed on the floor, held in place with the feet, when used. There are few operations in modern woodworking where such a tool might be needed; but if you are intent on only using the old methods, without electric power, the auger could be useful.

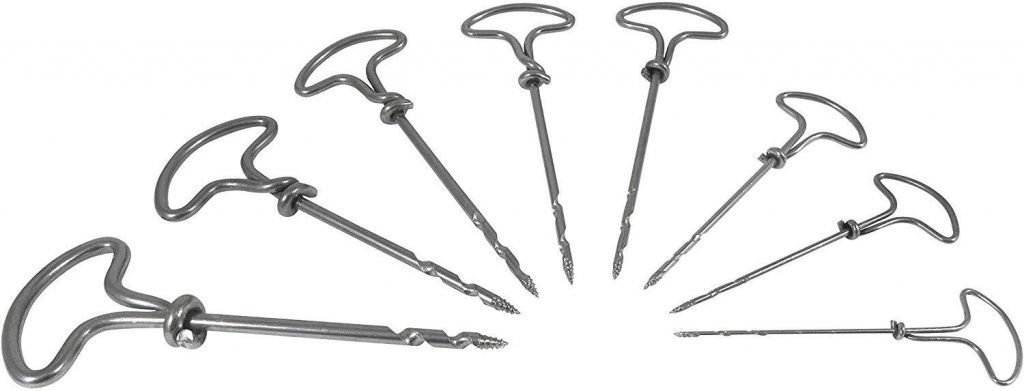

The Gimlet

While not referred to as an auger, the gimlet can actually be considered another auger tool. These small hand tools are usually sold insets, and were the preferred small hole drill for making holes quickly, where extreme accuracy may not be required.

The gimlet has a screw tip, like any other auger bit, and it also has a T-handle (sometimes a “D” handle). But that’s where the difference ends. Rather than using a spade bit, the screw tip leads to a tube, which is spiral cut with a sharp edge. When used, the screw tip draws the tool into the wood, creating a small hole by pushing material aside. As the tube edge reaches the wood, it cuts these wood fibers, which have been pushed aside, creating the hole.

Due to the small handle, with minimal leverage, the gimlet is limited to only small sized holes. A set of gimlets will range in size from a minimum of 1/8” to a maximum of ¼” or from a minimum of 1mm to 5.5mm. They may be stamped with number sizes, rather than dimensions, as the sizes generally match wood screw sizes, as the major use of the gimlet is to drill pilot holes for use with wood screws. The tapered gimlet works ideally with the tapered design of wood screws.

Hand Brace Drill

The most common woodworking auger is the “hand brace.” This is the “motor” for drilling with auger bits in sizes from ¼” up to over an inch. When used in conjunction with forstner bits, rather than auger bits, the hand brace can drill holes up to a little more than an inch in diameter. High accuracy can be maintained, but requires some practice on the part of the woodworker.

The hand brace is essentially a crank, used for driving an auger bit into the wood. These come in a number of different sizes, as expressed in the handle “sweep.” But they can differ in other ways as well, most especially in the chuck that holds the auger bits.

The sweep of the brace is the measurement of the circle made by the offset handle, when using the brace to drill holes. A 10” sweep means that the centerline of the handle will scribe a circle that is 10” in diameter, centered on the hole which is being drilled. However, you may need more or less space for the hand that is providing the drilling power, through that handle. In 360° operation, you would need at least a couple of inches additional space, all the way around. However, the drill chuck is ratcheting, so you could drill by making an arc, rather than a full circle.

The other handle of the brace is there to provide downward pressure, driving the drill bit, most especially the screw point, into the wood to be cut. It is usually built with ball bearings, to provide minimal resistance. Likewise, the chuck head will be oil filled for minimal resistance when using a ratcheting operation.

These tools come with either a three-jaw chuck (shown) for use with round our hexagonal shafted auger bits. Older varieties may also come with a tapered square four-jaw chuck or a slotted chuck for use with auger bits that have what looks like a straight-bladed screwdriver blade sticking out the back end. This protrusion on the back end of the bit fits into a slot in the brace’s chuck, preventing it from spinning when torque is applied.

Egg Beater Drill

Although the egg beater drill is not ever used with auger bits, it is worth mentioning here, as it is another old-style drill, used primarily in a time before power tools existed. The name comes from the similarity in operation between the drill and old hand-crank egg beaters used in the kitchen. These drills work with bits up to a maximum size of ¼”.

The advantage of an egg-beater drill, for the modern woodworker, is that it can be used with either normal split-point drill bits or brad pointed drill bits; drill bits that they are likely to already have in their workshop. This makes switching over to the use of an egg-beater drill easy for the woodworker. They are also considerably cheaper, making the addition of an egg-beater drill something that won’t but much of a dent into your tool buying budget.

These drills are used for precision drilling, both in hole location and the perpendicularity to the work surface. It is easier to hold an egg-beater drill straight when using it, preventing wobble of the drill bit, than it is to hold a brace without allowing any wobble. It is ideal for drilling pilot holes or holes for pegging with dowels.

Some older egg-beater drills had two-speeds. This was accomplished by having two pinion gears of different sizes. The larger of the two allows for a slow speed, when extreme accuracy and control are needed. This is especially useful in operations such as drilling a hole, where you need to be careful not to drill through to the other side of the workpiece.

The size of the drive wheel (gear) makes a huge difference in how fast these drills operate. Although the speed is controlled by the ratio between the drive gear and the pinion gear, generally speaking, the larger the drive gear, the faster the rotation of the drill chuck and the faster the drill bit will cut.