Crafting Cabinet Doors Like a Pro with the Kreg Jig

Building your cabinet doors doesn’t have to be a complicated process. With the Kreg Jig, you can create beautiful, sturdy doors without needing to be a woodworking expert. Whether you’re working on a kitchen upgrade or a custom project, this tool is a total game-changer. Let’s dive into why the Kreg Jig should be your go-to for cabinet doors.

What Exactly is the Kreg Jig?

The Kreg Jig is a tool that lets you drill precise pocket holes in wood. These pocket holes make it easy to assemble pieces without showing visible screws. Perfect for cabinet doors, the Kreg Jig ensures strong joints lasting for years with minimal hassle.

Why Should You Use the Kreg Jig for Cabinet Doors?

- Super Strong Joints – The Kreg Jig gives you clean, secure pocket holes, ensuring your cabinet doors are strong and built to last. No more worrying about flimsy joints or unsightly screws!

- Quick Setup, Quick Results – Whether you’re a beginner or a seasoned pro, the Kreg Jig is easy to set up and use. It’s perfect for anyone who wants to spend more time building and less time figuring out complicated tools.

- Flexible for Different Designs – No matter the thickness of your wood or the style of your cabinet doors, the Kreg Jig can adjust to fit your needs. From classic shaker doors to modern looks, it’s a versatile tool that fits a variety of projects.

Step-by-Step: How to Use the Kreg Jig for Cabinet Doors

- Cut Your Wood to Size – You’ll want to cut your door pieces to the correct dimensions. Measure carefully to ensure everything fits together like a glove.

- Set up the Kreg Jig—Adjust the Kreg Jig to match the thickness of your wood. Clamp your pieces in place, and get ready to drill!

- Drill Your Pocket Holes – Drill the pocket holes where your frame pieces connect. It’s as simple as lining up your drill bit with the jig’s guide, and you’re good to go.

- Assemble the Door – Now for the fun part: putting it all together. Line up your frame pieces and use Kreg screws to hold them in place. The pocket holes create a tight, clean connection, ensuring your door is sturdy and looks great.

Pro Tips for Success

- Always test on scrap wood before drilling your actual pieces. This will help you get the settings just right.

- Match the screws to the thickness of your wood – this makes sure the joints are as strong as possible.

- Keep your pocket holes spaced evenly for that flawless, professional finish.

Wrapping It Up

The Kreg Jig makes creating cabinet doors much easier, and the results speak for themselves. Whether you’re a DIY enthusiast or someone with more experience, this tool helps you craft strong, clean, and beautiful doors with minimal effort. Its ease of use and versatility make it a must-have for any woodworking project. So, grab your Kreg Jig and start building – you’ll be amazed at what you can create!

Kreg Tool is one of many small tool manufacturers that produce a limited line of really excellent tools. It’s hard to say what they are best known for, but their pocket hole jig has revolutionized the way that cabinetry is made. It provides a fast, easy, and accurate way of making pocket holes, allowing wood framework, such as cabinet facings and doors, to connect quickly and accurately.

The idea of making pocket holes to connect wood pieces together is nothing new. I have seen examples of pocket holes in furniture that is over 100 years old. But those examples were pieces made by highly skilled woodworkers. Moving forward in time, we can find examples of factory-made pieces that use pocket holes. Even though I was not there to manufacture them, I am sure those pocket holes were created using custom-made jigs and tooling.

Before jigs, master craftsmen created pocket holes by drilling perpendicularly into the wood stock and then tilting their drill to make the pocket. Brad-point drills were actually invented to make this process easier. I was taught it once, but I must admit that I never mastered this skill.

The Kreg Pocket hole jig makes it possible for any woodworker to do what I didn’t succeed in the “old ways.” The jig, which clamps to the workpiece, provides precise alignment for drilling the pocket hole into a piece of wood so that it can be joined at a 90-degree angle to another, either in a T configuration or an L configuration.

Ok, so why would anyone do this?

Three other methods exist to join such pieces: mortise and tenon, doweling, and biscuit joining. Both mortise, tenon, and doweling are more challenging to master, with a greater chance of making errors. It’s also harder to make tight joinery with either of these methods without considerable skill, which comes from considerable practice. Biscuits don’t produce accurate joints because they sit loosely in the slot cut by the biscuit joiner. The tightness of the joint comes from how well it is clamped together while the glue is drying.

On the other hand, the Kreg Pocket-hole jig allows woodworkers of moderate skill to do this work right, making tight joints the first time. As long as the jig and drill are set up properly, they will produce clean, tight joints every time.

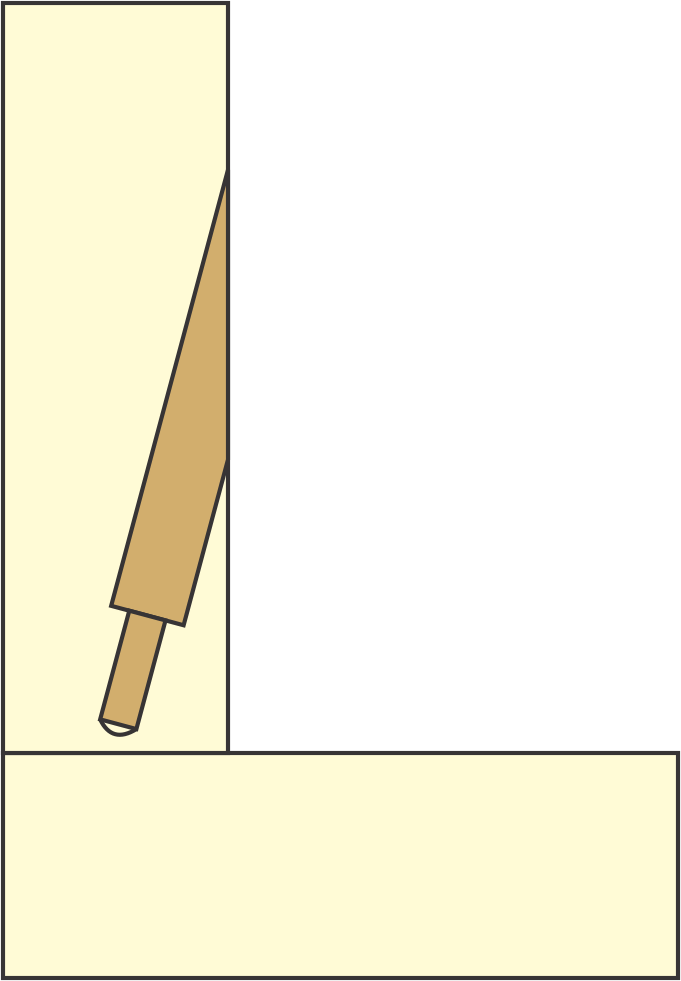

Pocket joinery provides a hardware joint to replace mortise and tenon or doweling. To do this, it is necessary to insert the screw at an angle, which is the purpose of drilling the pocket hole. Producing a hole that is drilled at a shallow angle to the surface allows the screw to go through the bottom of the hole and into the adjoining piece without coming out the side.

More than anything, the pocket hole jig provides bushings to guide the drill bit as it makes the hole. The hole depth is critical and is controlled by attaching a collar to the drill bit. This collar is set to the exact distance necessary so that the screw’s point will enter the second piece at the center of its thickness, a necessity for this sort of joinery.

Once the hole is drilled, round, ash head wood screws are inserted, holding the pieces together. These are usually driven with a square drive for maximum contact between the bit and the fastener. The wide tread of the wood screw is designed to dig deeply into the wood grain, providing excellent holding power.

The diagram above shows a pocket hole drilled into one piece of ¾” wood, preparing to attach it to a second piece at a right angle. The same hole can be used when connecting two pieces flat, whether laminating pieces for a tabletop or making a cabinet door frame.

When making cabinet door frames, it is common to use pairs of fasteners at each corner. This provides a solid joint between the two pieces, preventing them from twisting.

Building a Cabinet Door with a Pocket Hole

Any cabinet door that is not made of a single solid piece, as is done with some modern styles, consists of a frame made of four pieces and a panel. The upper rail might be curved, depending on the style of the cabinet door being made, and the panel might be raised if that is desired. But in all cases, the same five pieces of wood are used.

Solid panel “European” doors are not made with this same construction, but that isn’t what we are referring to here. Those doors are designed to cover the entire cabinet face, whereas the more typical doors only overhang the cabinet face ½ inches, leaving some of the facing showing.

Typically, the cabinet is built first so the openings in the cabinet face can be measured for the doors. With a ½” overhang, the doors will be one inch taller and wider than the measured opening. So, the vertical stiles need to be cut one inch longer than the height of the opening. The horizontal rails, on the other hand, are cut shorter to account for the thickness of the stiles.

To calculate the length of the stiles, start with the rails, adding one inch to the opening. Then, subtract double the rail width to account for the two rails. This will give you the perfect dimension for the stiles.

With the rails and stiles cut to length, the pocket holes are drilled into the stiles. There are several different models of Kreg Pocket-Hole jigs, some of which come with built-in clamps and some of which do not. In order to fully understand how to clamp the jib purchased, it will be necessary to read the instructions for it. Depending on the model, the clamp may or may not be provided with the jig.

Since there is no alignment necessary between this hole and the rails, as there would be with doweling or a mortise, the location of the pocket holes isn’t critical. However, the jig must be set up correctly on the workpiece so that the bottom end of the hole aligns with the center of the board. For ¾” thick stock, this is accomplished by aligning the end of the jig with the end of the board when clamping them together. For working with ½” thick stock, the jig would be positioned ¼” beyond the end of the board being drilled and for 1-1/2” thick stock it would be placed 1-1/4” back from the edge. However, almost all cabinet door frames are made from ¾” thick stock.

The special stepped drill bit used with the Kreg Pocket hole jig needs to have the depth stop attached. For 3/4” thick stock, this should be 3-1/2” from the step in the drill bit. For ½” thick stock, it should be 3-5/16”, and for 1-1/2” thick stock, position it 4-1/4” from the step.

| Material Thickness | Position Jig | Position Drill Stop |

| ½” | ¼” overhang | 3-5/16” |

| ¾” | Flush with end | 3-1/2” |

| 1 ½” | 1-1/4” back from edge | 4-1/4” |

It is recommended to use a corded drill that turns at a minimum of 2,000 RPM to drill the hole into the wood, as a lot of torque is required. Not all cordless drills have enough torque to drill the hole. Go all the way to the stop. Most Kreg Pocket Hole jigs allow two to three holes to be drilled side by side.

The rail and stile can be connected to form the first corner with the hole drilled in both stiles. Even though gluing into end grain is not usually recommended, it is a good idea to do so in this case. Glue the end grain and then set it in place, face side down, and align it perfectly with the surface and edge of the rail. Clamp it in place, then drive the screws in with an impact driver.

Repeat this procedure for each of the corners. The screw should pull the joints in tight, giving perfect joints every time, as long as the material is appropriately aligned and tightened.

With the frame connected, there is no need to wait for the glue to dry before continuing. The screws are acting as both the clamping system and fasteners, keeping the frame together. Place it face down on the workbench surface and route out the rabbet on the inside back of the frame for the panel to set into. Use a bearing on the bit to align the cut with the edge of the frame. This would be ½” deep and ¼ to ½” wide with most designs. The corners need to be cleaned with a chisel, as the router bit will leave them rounded.

If the edges of the door are to be sculpted in any way, either on the inside or outside of the frame, they should be cut with the router now. Cut several passes, only significantly taking off a small amount of material each, when cutting across the grain. Allow the final pass to be minimal to smooth out the surface of the cut.

For a flat panel, cut the panel out of 1/4” thick cabinet-grade plywood to fit in this opening, making it 1/8” shorter and narrower than the routed rabbet to allow for expansion during times of high humidity. If raised panels are to be used, they should be the same size, with the edges ¼” thick. Also, cut 1/2” x 1/4” strips of the same material that the door frame is made of to hold the panel in place.

Set the door panel into the rabbet so that there is 1/16” of space all the way around. Then set the strips over the edges of the panel, nailing them into place with 5/8” brads, through the edges of the panel, and into the frame. Ensure that the nails do not come through the other side. No glue needs to be used.