Building a floating, wall-mounted desk for modern office furniture requires a different style and special techniques.

You can’t make a “floating” desk like any other because the floating, wall-mounted desk doesn’t have legs. Instead, it is attached to the wall in such a way as to make it look like the desk is floating in the space in front of it.

Modern architecture often requires modern furnishings to blend and match. Putting a Queen Anne-style table into a current home looks out of place, just like modern furniture would look out of place in a Victorian-style home with gingerbread trim.

The problem with the two wood desks is making sure they are strong enough to sit on, even though they don’t have any visible means of support.

That requires making good use of materials and features such as solid joinery techniques. There’s no room for slop in a floating wood desk, as any movement could ultimately lead to the desk falling off the wall, perhaps with disastrous results.

Floating shelves are much more common than floating desks simply because making a floating shelf is easier.

Both floating shelves and desks are generally less than 12” deep, while a standard desk is between 24” and 32” deep.

However, a floating desk 18” deep is more common, as the greater the cantilever of the desk, the more stress it puts on the wood of the mounting. This increases the chances of the desk breaking and falling off the wall if it is not properly made or if too much weight is put on it.

Even so, a simple floating desk mount can be counted on to hold a desk between 30 and 75 pounds. That’s enough room to set a computer on it and use a mouse and keyboard without a problem. If more weight capacity is needed, consideration must be made with additional support for the desk hidden in a small space between the floating desk mount and the wall. With the proper structure in the wall and a solid connection to that structure, a floating desk mount can hold a desk of up to 300 pounds.

Using Commercial Brackets to Make a Floating Desk

Various manufacturers produce several different brands of floating wall-mounted desk shelves and brackets on the market.

The nice thing about using these is that they make the installation job considerably more accessible while still giving the do-it-yourselfer the flexibility to create and vary the interior design details of their desk.

The brackets are quite sturdy. Many of them can hold 90 to 225 pounds, and some can hold 1,000 pounds.

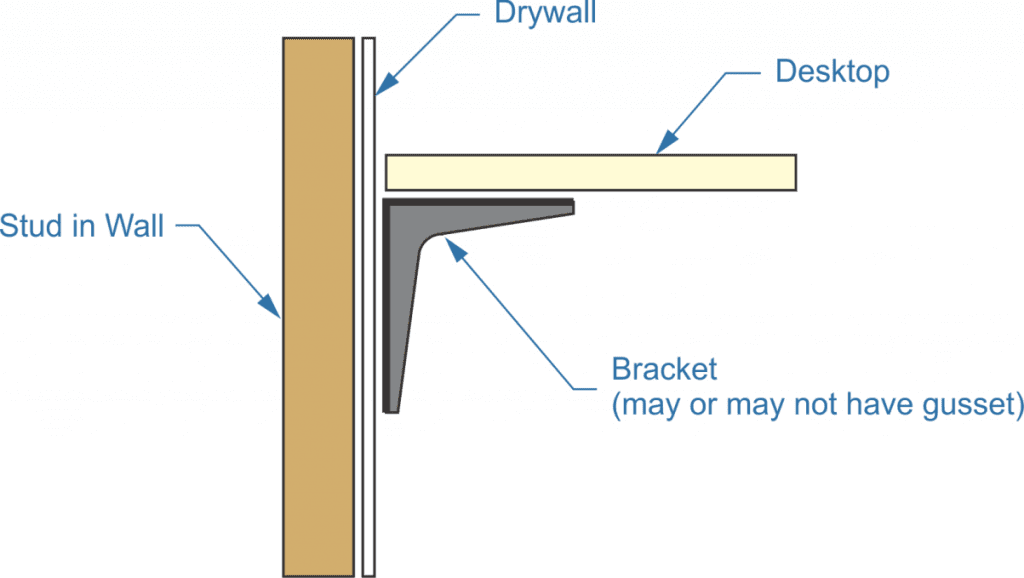

But these aren’t as invisible as standard wood shelf brackets, where a vertical metal leg goes between two wood shelves mounted up and down the wall. Still, if used properly, the desk’s height and depth will hide the bracket, making it virtually invisible and maintaining the perception of the desk floating.

These brackets must be mounted to studs in the wall rather than just to the drywall. The drywall doesn’t have any real structural strength. So, if any pressure is placed on the surface of the wall space, for example, the computer, desk, or table is mounted or sitting on, there’s a good chance that the mounts will tear right out of the wall.

Even using sturdy molly bolts or toggle bolts won’t provide the desired strength, as the structural weakness is more in the drywall than the fasteners. Toggle and molly bolts are rated at 30 to 50 pounds.

A true floating computer desk will hide the brackets within its body. This means that if the computer desk is constructed from wood slabs, holes will need to be drilled into the edge of the wood slab to provide enough storage space and floor space to accommodate the fingers of the bracket on floating desks.

Commercial pocket bracket

The illustration above shows this sort of bracket.

They drill and must be straight into the edge, parallel with each other. If they are not, then the desktop won’t fully slide and sit onto the bracket.

The other commercial floating corner desk bracket style is more robust and easier to install and work with. However, seeing what’s holding the floating wall desk back up is more manageable, especially if someone gets down on the floor to look under it.

The basic front wall corner desk mount mounting is shown in the diagram below, shown from a side view. Links to the various parts are exploded for clarity.

Commercial L bracket

A rather ingenious variation on this bracket is designed to mount the wall desk directly to the stud, with the horizontal metal section not going through the drywall.

This particular bracket needs to be installed before the drywall is, or a section of the drywall will need to be cut out, and the brackets will need to be installed. After that, the drywall was refinished for use.

Still, it provides considerably more strength than a typical L bracket, even though it doesn’t have a gusset. All that is sticking out is a flat piece of ¼” thick flat steel strip, which is hard to see without underneath the wall desk mount.

Making a DIY Bracket

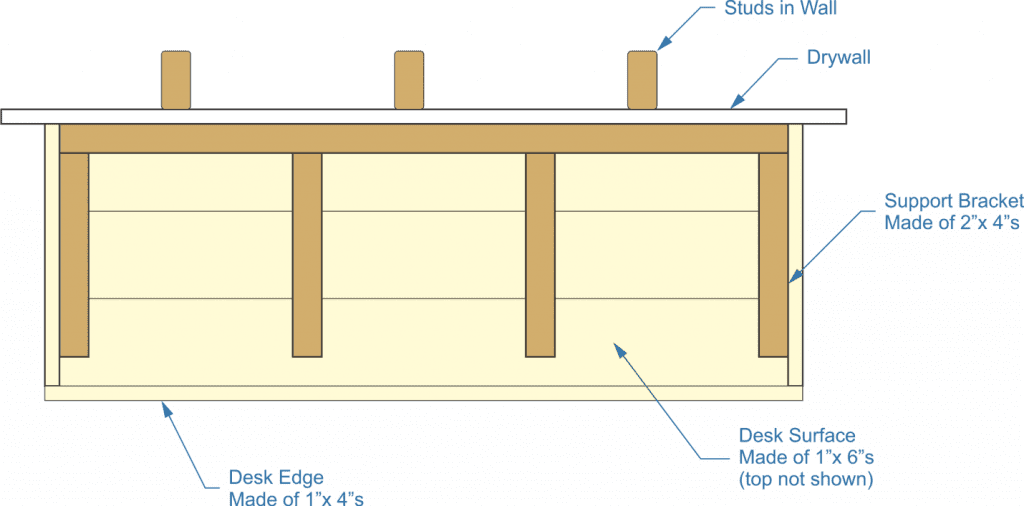

For the do-it-yourselfer, the first table bracket above the diagram provides the basics for making two shelves for our side table brackets out of 2”x 4”s. The desktop table can then be made hollow to make shelves to cover the side table bracket, hiding it and providing a desktop tabletop surface.

Homemade desk bracket

The bracket consists of a back piece that attaches to the wall, with as many supports extending perpendicular from the wall mounted to it as needed for the width of the wall mounted to the computer, laptop, or desk.

It is recommended to have a brace every 16” to provide sufficient support and keep the computer, laptop, or desktop surface from sagging when pressure is put upon the wall mounted to it.

Before building the shelves to fit into the space under the support bracket, run the 2”x 4” through the table saw, ripping them to make them 1/16” to 1/8” thinner in the 4” dimension. This will create a small amount of clearance that will allow the shelf to slip and fit onto the support bracket once the bracket is attached to the wall.

The pieces of the support need to be cut square in both directions. First, make a test cut on the saw to verify that it is properly aligned. All stationary power tools, especially saws, are designed to be adjustable to compensate for manufacturing tolerances.

When the saw arrives, it usually needs to be set up, making these adjustments. If it is not adjusted correctly, there is a good chance of gaps in the joints between the back piece of the extensions on the support, weakening it. Tightening whatever fasteners are used to fill those gaps will tend to make the support out square.

Fasten the pieces of the support bracket together with either screws or nails, along with glue. A minimum of two fasteners should be used for each joint. Nails are generally stronger going into the end grain than screws are, so that is the preference.

Adding glue to the joint won’t make it considerably stronger but will help prevent squeaking. Clamping the joints together before inserting the fasteners will help ensure the entire assembly is square.

Once the support bracket is built, the desktop has 1”x 4”s and 1”x 6”s around the bracket. The diagram does not indicate this, but the 1”x 6”s used for the top and bottom shelf sides run the entire length and depth of the shelf, with the 1”x 4”s making up the front and blackboard side edges fitting between them.

This assembly order, coupled with the ripping down of the 2”x 4”s earlier, will allow the bracket to be hung on the wall and then attached to the desktop.

Several different fasteners can be used to assemble the desktop, but I’d recommend using a pneumatic finish nailer and glue. The small hole will be easy to fill, and the combination of nails and glue will eliminate any need for clamping while providing sufficient strength.

Take care not to nail through the 1”x 4” and 1”x 6” of the desktop into the bracket.

Mounting the DIY Floating Desk

First, hang the desk on the wall shelves, separate the desktop from the wall shelves, and install a blackboard support bracket. Drill and countersink a series of clearance holes into the back stringer of the support bracket, spaced at 16” to line drawers up with the studs in the walls.

Then set the bracket against the wall shelf at 29 1/4” above the floor, and screw through one of those holes into the stud in the wall shelf. Then use a level to adjust the position of the bracket level before installing the rest of the screws.

With the support table or bracket mounted to the bedroom wall, the desktop can be slid over it, pushing it up against the wall.

Holding it there or having an assistant hold it there, go under the desk and fasten the bottom of the desktop to the floor space or the mounted support table or bracket in the room in at least two places, by inserting screws or nails through the desktop and into the 2”x 4”s of the bottom space or bedroom wall mounted support bracket. If the desk might be moved sometime in the future, it would be best to use screws to attach the two.

Mounting the DIY Floating Desk Without Making Holes in the Wall

People with kids who live in apartments are plagued by landlords who don’t want them to play and make holes in the walls. While this is understandable from the landlord’s point of view, it can make decorating things extremely difficult.

3M has come up with at least a partial solution for this problem with their Command™ line of adhesive products for hanging things on the wall. While not as strong as screws and nails, they make it possible to hang pictures, shelves and drawers, and even floating desks on the wall.

The key here is weight capacity, as the strongest of these I can find is rated at holding 8 pounds. To compensate for that, several of the hangers need to be used in multiple sizes.

Using those hangers on the second type of commercial bracket shown above will provide the most strength, as the bracket’s vertical leg provides considerable leverage.

The other thing that can be done, using the Command™ system, is to build the floating desk to sit in the corner rather than just protruding out from the wall. Having it sit in a corner gives a more linear surface to attach the hangers to the shelves and lessens the amount of cantilever, reducing the stress on the fasteners. No matter what you decide, the floating desk won’t have a high weight rating, but it will be improved.

Design Modifications

While the basic floating desk is nothing more than a desktop, the basic design can be modified considerably to meet your needs and taste.

The most straightforward possible modification is to make the drawer below the desk a shelf shallow box, with the drawer at the front open. This provides space for two shelves and a slot below the desktop drawer where papers, pens, and office work supplies can be stored.

If more is needed, the best thing to do is make a wall-mounted cabinet with slots for organizing papers, cables, and office supplies. This would be something like a desk riser that provides storage space above a desk for organizing the various things used there.

The only real difference is that the laptop desktop and organizer would be sold and built together, making a wall-mounted computer hutch. Design possibilities for this are endless and depend more on the space available for the laptop computer and office storage space itself than anything else.