The idea of the chuck box came from the Old West cattle drives. Contrary to what most people think, the chuck wagon wasn’t filled with food. Most of that space was taken up by the cowboys’ bedrolls, which could get quite heavy, as they contained pretty much all of the cowboy’s possessions. The chuck box on the back of the wagon was the domain of the camp’s cook, where he kept their food, dishes and cooking utensils.

Those original chuck boxes could be quite large, rising as much as four feet above and two feet below the bed of the wagon. They had to be, in order to hold everything they would need. While traveling, the back end of the chuck box would be closed up by a large door, which folded down to become the cook’s table when in camp. The cook would keep their chuck box superbly organized, with a place for everything and everything neatly stashed away in its place.

This same general idea has been adopted by many for camping, especially tent camping. Considering how many of us have trucks or SUVs today, the chuck box just seems to be an ideal way of organizing our camping kitchen and ensuring that everything stays packed and ready to go. When we get to our campsite, the chuck box can sit on a picnic table, the tailgate of our truck or the load bed of a SUV, giving us an instant kitchen.

These chuck boxes can vary greatly in size and shape, depending on your personal camping style, how much storage room you need in it and how much you’re willing to invest in making yourself your ideal camping kitchen.

A Few Design Considerations

While the basic idea of the chuck box comes from the trail drives in the Old West, times have changed considerably. We no longer camp for months at a time, while driving cattle to market. Today we’re more likely to go camping for a weekend of fishing or maybe even a whole week as a family vacation. That’s about it. So we don’t need someplace to keep our food so much as someplace to keep our plates, pots, pans and utensils all organized and ready to go.

We also don’t have any need to permanently mount our chuck box to the back of a buckboard wagon. Rather, it needs to be something portable. So, here are a few design considerations to take into account, when designing a chuck box:

- Weight is a consideration. At some point, someone is going to have to pick the chuck box up and put it in the vehicle, as well as take it out to put on the picnic table.

- It has to be able to fit into the vehicle that will be carrying it, along with all the other camping gear.

- While the camp boxes used on chuck-wagons needed to have the door fold down to make a table, today’s don’t necessarily need that. Doors can fold up or to the side, providing space for storing small items.

- The more compartments in the box, the easier it is to organize; but at the same time, there’s a need for larger compartments for plates, pots and pans.

- Things might move around in the chuck box if they do not fill the area or are not held in place by something.

- Any camp box needs handles on it, so that it can be picked up and moved.

- To help keep the weight down, 1/2” thick plywood is ideal. However, care will have to be taken in pre-drilling all joints, so that the plywood doesn’t split from inserting fasteners.

With those thoughts in mind, let’s look at making a chuck box.

Many people build their camp stove into the chuck box, which is extremely convenient, putting everything within reach, while cooking. So the starting point for any box is measuring the size of the camp stove that is going to be used. The upper part of the box has to accommodate this stove. For the sake of this article, I’m using a Coleman Dual-Fuel stove, which measures 18” W x 12” D x 5 ½” H. For a larger camp stove, adjust the dimensions accordingly.

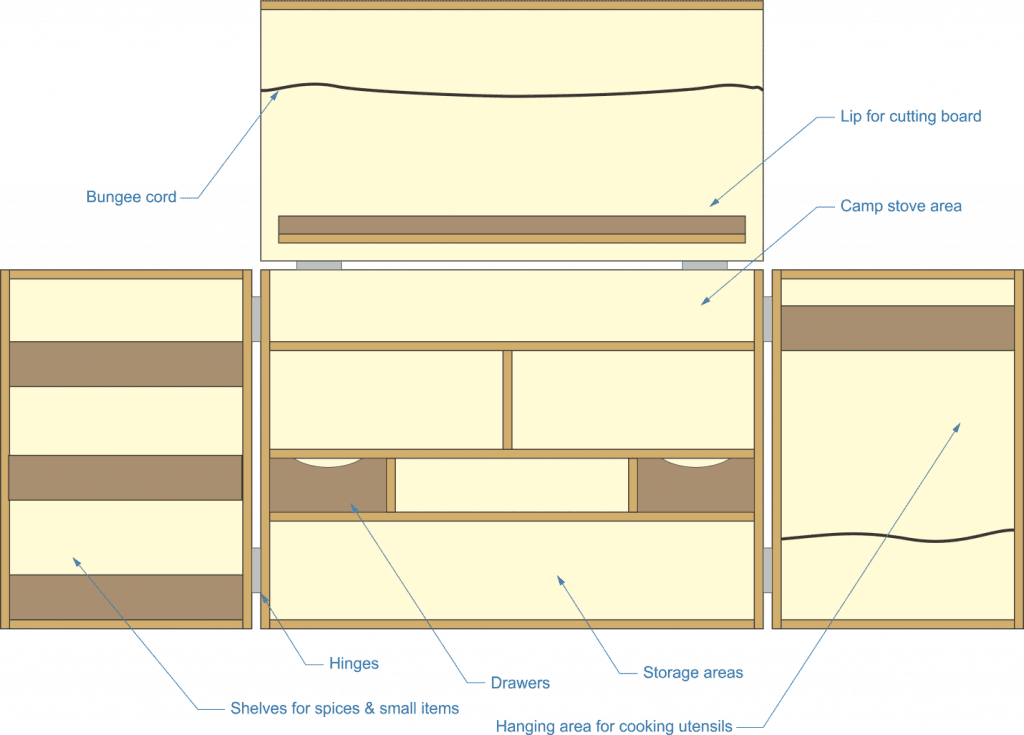

The drawing above gives you a general idea of the overall plan for the chuck box. This particular design combines the best features from a variety of other designs, in an attempt at creating the most versatile chuck box possible.

The two drawers would be used for storage of utensils, while the larger storage areas would be used for storage of plates, cups, pots and pans. The size of any of these compartments could be adjusted, simply by moving any of the dividers.

Making the front hinged and about two inches deep creates storage space in the doors for a spice rack on the left and for hanging cooking utensils (spoon, spatula, fork, etc) on the right. Likewise, a small lip attached to the bottom side of the lid provides a place to hold a cutting board. Bungee cords hold the utensils and cutting board in place while the chuck box is being moved.

This diagram provides rough overall dimensions for the same chuck box. These can be adjusted as needed, to fit any particular camp stove or other requirements.

The main part of the box is 13” deep, as shown by the lid. The two doors in the front are roughly 2 ½” deep, on top of that 13”. This makes the whole thing 19.5” wide by 20” tall by 15.5” deep, large enough to meet most people’s needs, while small enough to fit into the back of any SUV.

Building the Chuck Box

One-half inch thick AB softwood plywood is ideal for making this chuck box, as it is less expensive than hardwood plywood, while still providing enough strength. While ½” plywood is a bit difficult to connect together at corners and other joints, going with thicker plywood adds unnecessary weight.

The key to joining the plywood parts together is to clamp them, pilot drill and countersink the holes and then put the screws in. Most people use drywall screws for construction of this type, which is fine; but flat-head wood screws with a square or TORX drive are better. The pilot hole should equal the diameter of the screw’s shaft, not counting the threads. This is called the screw thread’s “minor diameter”, while the overall outer diameter is called the “major diameter”.

As an alternative, brads from a pneumatic nailer can be used for attaching the pieces together. That gives the opportunity to use more fasteners, which will add strength to the box, especially during the key time while the adhesive is drying.

To provide added strength, if the chuck box is expected to receive hard use, a ½” or ¾” square piece of dimensional pine can be cut and fitted into the corners of the case. This will increase the amount of surface area for gluing, providing a considerably stronger glue joint than can be had just by gluing the edge of one panel to the side of another.

The dividers inside the box are made of the same ½” thick plywood as the exterior of the box. However, it would be a good idea to use thinner ¼” thick plywood for some of the non-structural divider parts, such as some drawer parts, the spice rack fronts and the front lip of the holder for the cutting board.

Finishing the Chuck Box

The Chuck Box must be protected from the weather in order to protect the plywood from damage. In most cases, this means varnishing the box, but I would recommend using clear epoxy instead. Epoxy is much less likely to be affected by rain and it is food-safe. Finish it both inside and out, either with or without staining.

Clear two-part epoxy, of the type which is being used for “river” countertops can be purchased from a number of sources and will work ideally for this purpose. However, it is best to have a potting compound with a ½ hour or 1 hour pot life.

As an alternative, it is possible to point the chuck box, which might be easier. It might also show any damage to the finish better, making it obvious when repainting is needed. However, chips in the paint will probably cause the box to not look as good, as it would if it was varnished or epoxied.