Traditional fireplace mantels are mounted on two square pillars, one fireplace mantel being on either side of the other fireplace mantel. This was so commonplace at home at one time that many consider the pillars part of the fireplace mantel.

But more recently, the design of fireplace mantels has changed and become modernized. This modern move has included the elimination of the pillars, using a much simpler “floating” fireplace mantel.

The mantel shelf isn’t floating, although that’s what it is called. Much like a traditional floating shelf, the mantel shelf mantle is attached to the wall above the fireplace. The term “floating” comes from the fact that what’s holding the floating mantel shelf mantle in place isn’t visible.

This is accomplished by hiding the mounting bracket inside the mantle rather than using columns, floating shelves, or corbels underneath it. Besides appearing to flow, the overall appearance is a modern, clean look while still providing the space to display family mementos above the fireplace.

The two fundamental differences between a fireplace mantel shelf and a floating shelf are dimensions and mounting, so the workout doesn’t change to replace one with the other. A fireplace mantel shelf, even a floating one, is generally much thicker than a floating shelf and is only about seven inches deep.

Using a two-inch wide shelf instead of a fireplace mantel or floating shelf would look thin and cheap. The other big difference is that the fireplace mantel is generally mounted into brick or stone. In contrast, a floating shelf will typically be mounted into a drywall wall, with the bracket attached to the studs.

Several ideas, options, styles, materials, and ways to install a floating fireplace mantel exist. While they all share things in common, we’ll explore the various options.

Commercial Fireplace Mantels

A quick search online will result in various commercially manufactured floating fireplace mantels in various price styles and materials, ranging from rustic and live edge to sleek and modern, with rural and reclaimed wood in the middle.

I’ve found walnut and maple live and life edge fireplace mantels, and I’m sure they’re available in various other styles and types of hardwoods.

All of these fireplace mantel options use the same bracket, consisting of a piece with a metal plate cut out, with fingers sticking out. Those fingers are inserted into a matching hole cut in the fireplace mantel, holding it in place. Properly mounted, the unit can weigh about 75 pounds when installed.

Commercial floating mantel

The trickiest part of this build is installing hardware for the bracket. Different fasteners can be used; options vary, including Tapcon connectors, wedge anchors, and lag bolts into sleeves.

Regardless of the type of connector material used, a hammer drill and masonry bit will be needed to drill holes into the stone or brick to install the concrete. Trying to dig into even brick mortar with standard drill bits or even with masonry drill bits and a regular drill is a waste of time; both the masonry drill bits and the hammer drill are required.

Once the shelf bracket is ready and firmly installed, the shelf fits over the fingers. There’s usually someplace where a small screw is inserted in a hidden location to prevent pieces of material from the shelf from sliding off the shelf bracket.

Using a Commercial Bracket with a Homemade Mantel

The same styles of material and brackets sold with modern, commercially manufactured floating fireplace mantels can be purchased separately and ready for easy use in the home for installing homemade fireplace mantels.

This allows us to design, build, and install our own floating fireplace mantels without the difficulty of having to come up with materials and a bracket for them.

The one challenge in using these brackets for a homemade mantel or floating shelf is the pocket hole for the bracket’s fingers. Those have to be drilled straight into the bottom fireplace mantel shelves to slip the mantel shelf onto the bracket.

If any of them are crooked or twisted in different ways, there’s a good chance that the mantel shelf won’t slip onto the bracket. This is better for a mantel shelf than for floating shelves, only because the bottom fireplace mantel for floating shelves generally isn’t as deep.

To ensure that the dimensions of the hole are drilled straight and accurately, it would be best to use a drill press. If one isn’t available, making the holes slightly oversized may be necessary to accommodate any change in material, dimensions, or deviation from the holes being straight.

As discussed below, adding something to make the mantle a box design piece is another easy option. This piece can then be mounted around the fingers on the bracket, eliminating the risk factors of drilling holes for pieces that don’t match or line up right.

Making a Homemade Mantel and Bracket

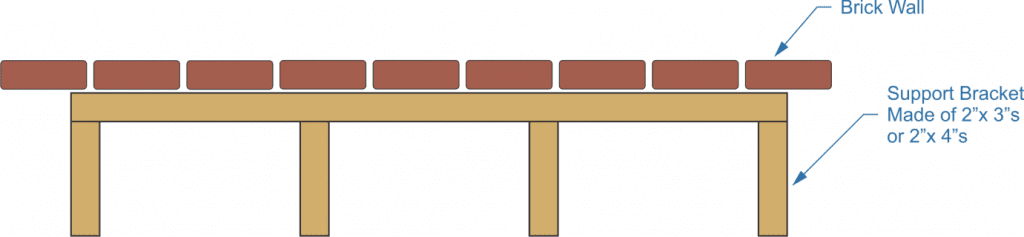

A homemade bracket can be assembled out of boards for a homemade bracket. This can be done out of 2″ x 4″ s or 2″ x 3″ s, prices of which vary depending on how high fireplace mantel shelves the mantle will be in the living space. A 2’x 4″ bracket would be more stable than a 2″ x 3″ one, assuming there’s enough room to fit it inside the living space on the fireplace mantel.

The idea is to make and install the bracket at home in much the same way that the modern commercial ones are, with the main difference being that at home, it is made out of pieces cut out of wood rather than metal.

The cut-out pieces must be all square, especially the fingers’ ends, as they must butt up square against the wall plate. Attach them securely with at least two screws or nails and attach the bracket to the wall like the modern metal bracket. Of course, longer screws or bolts will be necessary.

Homemade bracket

If there is a problem with getting screws or bolts long enough to anchor the bracket to the wall properly, it might be necessary to counterbore the bracket’s wall plate. This means drilling a larger hole partially through the board for the head of the fastener.

For example, a 1″ diameter hole might be drilled halfway through the board with a spade bit or Forstner bit for the head of the bolt, with a ¼” clearance hole cut through the board the rest of the way for the shaft of the bolt to go through and into the space for the anchor in the wall.

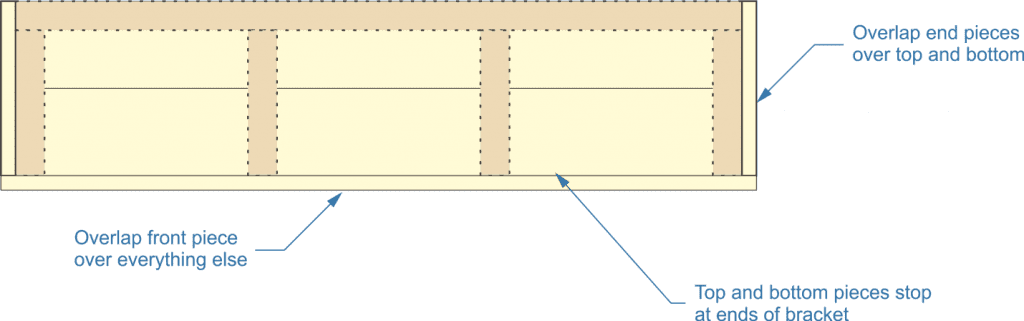

With the bracket hung, the rest of the floating fireplace mantel is nothing more than a box that fits snugly over the bracket. It is usually made of 1″ x boards, with the layout of the pieces done in such a way as to hide the end grain of the boards, as shown in the diagram below.

Homemade mantel box

A Word About Style

Since modern floating fireplace mantels are a contemporary style of fireplace, they are usually relatively simple, using material such as a plain box. This is not an absolute requirement, though.

There is plenty of room for creativity in making a perfect homemade floating fireplace mantel, with ideas including relief carving the face of the fireplace mantel and the two fireplace mantel shelves to match the room’s décor.

Some people even use architectural moldings, attaching combinations of styles of pieces around the basic box to make a more modern, traditional-looking floating mantel.

That would be a perfect crossover between a traditional and contemporary mantel style. In such cases, it’s a good idea to add that, to add a finish, and add, visually, to use corbels under the mantle in place of the columns that traditional mantels have. Finish such a mantel in a living space in a show space.