Many modern homes are built on concrete slabs instead of full basements. While basements offer extra space, they can be expensive, especially for first-time homeowners. However, when it comes to home upgrades, a concrete slab can present challenges—particularly when installing hardwood flooring. A plywood subfloor is essential to install hardwood over concrete.

Not all subfloors are the same. Typically, when people think of subflooring, they refer to lauan plywood, often used over thicker plywood when preparing for vinyl flooring. In such cases, the subfloor’s main purpose is to provide a smooth, level surface free from cracks or uneven seams.

However, for hardwood installation, a stronger subfloor is required. When laying subflooring over concrete, it needs to be thick enough for nailing. A minimum of 5/8-inch thick plywood is recommended, with 3/4-inch being ideal. This type of plywood is commonly used as sheathing in house construction and should be “exposure one subflooring,” which means it’s designed to resist moisture exposure during construction.

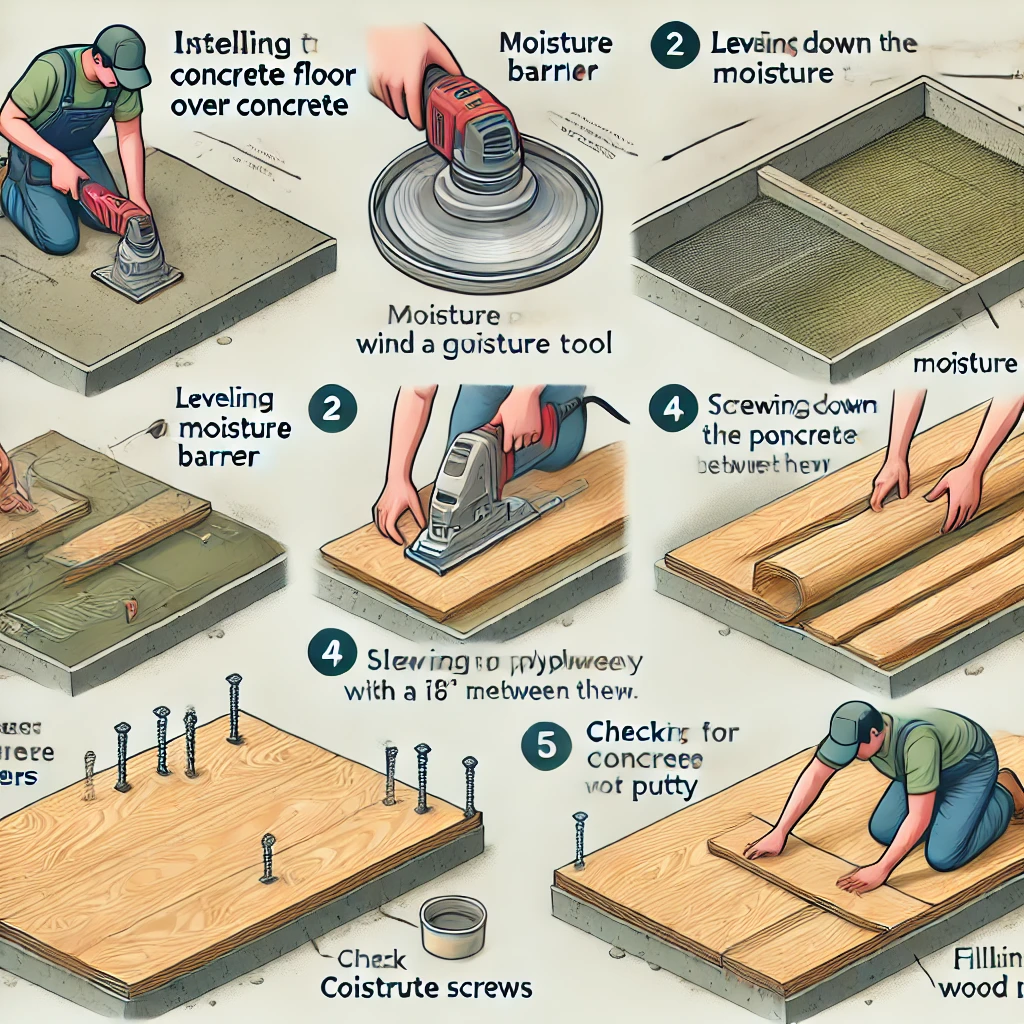

Moisture Levels in Concrete Floors

If you’re working with a dry concrete floor, you shouldn’t face any issues installing plywood. However, new concrete retains a lot of moisture. Before proceeding with the plywood installation, the concrete must cure for at least 60 days. The moisture content must drop to 5.5% before attaching the plywood. Floors below grade (e.g., basement floors) may never reach this low moisture level.

If your home has a history of flooding, you might want to reconsider hardwood flooring, as water can damage both the wood and its finish. In areas prone to flooding, hardwood floors are not recommended, as they will not last.

While 3/4-inch CDX plywood is a common subfloor choice, some suggest using pressure-treated plywood for additional protection. However, pressure-treated plywood isn’t necessary for basements, as the hardwood floor installed on top will not be pressure-treated.

Installing a Moisture Barrier

A moisture barrier is crucial to prevent damage from moisture that can affect the flooring. The type of barrier used will depend on the installation method:

- Nail-down Installation: Use 6-mil poly plastic sheeting or 15-lb roofing felt directly on the concrete before laying down the subfloor.

- Glue-down Installation: Plastic sheeting and roofing felt are not suitable for this method. Instead, use a trowel-applied liquid moisture barrier.

- Floating Floor Installation: Use 6-mil poly plastic sheeting as a moisture barrier under floating floors.

Some plywood subflooring products come with a moisture barrier already applied, eliminating the need for an additional layer.

Leveling the Concrete

Concrete should ideally be smooth and level when poured. However, this is not always the case. If the floor has uneven spots, these must be addressed before installing plywood. High spots can be ground down using a floor grinder (rentable), and cracks or holes can be filled with epoxy.

To ensure the floor is level, check by dropping marbles. If they roll to one side, the floor is out of level. If they congregate in one area, it’s a low spot. Mark high or low areas, then grind or shim them accordingly.

After preparing the floor, apply a latex bonding compound to ensure a strong bond for the self-leveling compound. Mix and pour the compound, smoothing it out with a garden rake. Allow it to dry for a few days before proceeding with the plywood subfloor installation.

Attaching the Plywood Subfloor

Once the floor is prepared and level, lay down the plywood subfloor. The plywood should be installed perpendicular to the direction of the hardwood flooring grain to prevent cracking along the seams.

Leave an expansion gap of at least 1/8 inch between the plywood sheets and a 3/4-inch gap around the perimeter of the room to avoid buckling. This gap allows for the expansion of the plywood when it absorbs moisture. The expansion gap will be covered by the baseboard once installed.

Methods for Attaching Plywood to Concrete

There are three common methods for securing plywood to concrete:

- Screws: Concrete screws (e.g., Tapcons) provide a strong hold. Use a hammer drill to create pilot holes and an impact driver to insert the screws. They should be installed every 16 inches, with the heads flush with the plywood surface.

- Powder Actuated Fasteners: Concrete nails shot into the floor are another option, but they can’t be reset once driven in. Test them first to ensure they work as expected.

- Adhesive Mastic: Mastic adhesive provides a moisture barrier while securing the plywood to the concrete. This method is more expensive but effective for creating a stable surface for flooring.

After installation, inspect the plywood edges for any ridges caused by uneven sheets. Fill any gaps with wood putty, then sand the surface to create a smooth, continuous base for hardwood installation.

Floating Floors and Alternatives

Floating floors are an increasingly popular choice. These systems use two layers of plywood with offset seams, and often include an underlayment pad made from cork or rubber. This method provides comfort underfoot and noise reduction.

Alternatively, plywood can be installed over battens (horizontal strips of wood) to create a floating floor effect. This is suitable for uneven concrete floors but requires careful leveling and shim adjustments. Battens should be checked with a laser level to ensure they are even.

Hardwood Flooring Directly Over Concrete

While not common, it is possible to install hardwood floors directly over concrete in dry climates. This requires specially engineered hardwood with a plywood core and a thin veneer on top. The concrete floor must be leveled, sealed, and a moisture barrier applied before installation.

In this case, the hardwood is glued down with polyurethane adhesive, and finish nails are used to secure the boards. Gaps are eliminated using a clamping device, ensuring a tight fit.

Vinyl Flooring Over Concrete

Vinyl flooring is a cost-effective alternative to hardwood. It can mimic the appearance of wood and is easy to install. Cushioned vinyl planks lock together around the edges, while non-cushioned vinyl requires full surface bonding with adhesive. Ensure the concrete is clean and free of debris before installation to avoid bumps or cracks.

Concrete Over Plywood

If you’re considering pouring concrete over plywood, the process is more challenging. First, ensure the plywood is rigid by adding a second layer. Install galvanized metal lath over the plywood for reinforcement, then apply a moisture barrier if needed. This method is useful for creating a subfloor for ceramic tile or even forming concrete countertops.