Quilt-making is not a uniquely American craft. Like many other things, it was brought across from Europe by early settlers. But in the United States, quilting came into its own as an artistic handicraft. Through the years, quilting has changed in many ways, with each era having its style and even purpose in quilting. The art form remains today in making patchwork quilts by hand and making “whole cloth” quilts on special quilting sewing machines.

Part of the reason for making those whole cloth quilts was because the fabric was not woven in comprehensive enough pieces to cover a bed. It was necessary to sew multiple pieces of fabric together to make a blanket that was both wide and long enough. At the same time, quilting covered the wool blankets that formed the insulating core of the quilt, making it more comfortable against the skin.

In the earliest days of American history, quilting was a luxury reserved for the wealthy, as only rich women had the time to make quilts. During that era, quilting was more of showing off one’s ability with a needle, with the stitching serving as part of the quilt’s decoration.

What most of us think of when we think of quilts is patchwork quilts. Contrary to common myth, these were not only made of sewing scraps and worn-out clothing, although those materials could be used in a patchwork quilt. However, many examples of antique quilts were made of all-new material. Yet the patchwork quilt retains a place in the heart of Americana.

All quilts are made of three primary layers. There’s the decorative face layer, the backing layer, and a filler. In olden times, that filler was usually a wool blanket, but in recent times it has been replaced by quilt batting, which is generally made of cotton and polyester, although it can also be made of bamboo. Even without any decoration, the actual quilting is needed to sew the three layers together in such a way as to keep them from shifting about each other.

Because of the work that went into hand-sewing a quilt, they are considered by many people to be family heirlooms. Rather than being used to keep warm in bed, they might be spread across a bed, not in use for decorative purposes. Some people hang the more beautiful ones on the wall as decoration.

Commercial Quilt Hangers

Several different types of commercial quilt hangers are available on the market. These range from things that look like unusual coat hangers to a series of wood screw clamps attached across one edge to hang the quilt. There are also wood hangers and a knick-knack shelf, where the quilt hangs on a wood bar suspended under the frame. There are even things that look like shower curtain hangers but with clips to hold onto the edge of the quilt.

Different quilt hangers pose problems for the person using them, such as folding them to fit on the hanger. This can hide the true beauty of the quilt, only showing part of it. But the more serious problem for those who own heirlooms or other antique quilts is finding a quilt hanger that allows the quilt to be displayed without damaging it. This requires some hanger that spans the entire width of the quilt, supporting it throughout the whole span. Hangers that clamp the quilt and hold it in specific points can allow it to sag between them, causing it to become misshapen. Some quilt hangers also require sewing a casing, such as on a curtain, to the back of the quilt, which nobody would want to do to a heirloom piece.

Some people use another option entirely: to hang the quilt from the ceiling. This is especially useful for larger quilts, which might brush the floor if hung on other hangers. A variety of self-stick hangers are available, which will not damage the ceiling. However, they still only hold the quilt at several points, allowing the fabric to sag between them. Care must also be taken to ensure enough hangers are used to support the quilt’s weight.

Probably the best possible option available is the compression quilt hanger. This eliminates the sagging problems caused by clamping onto only certain points while providing a hanger that will not damage the quilt in any way. Generally made of hardwoods, these hangers are also attractive without taking the focus away from the quilt. Their only drawback is that they tend to be a bit expensive. But that’s not an issue for woodworkers, as we can make our own.

Making a Compression Quilt Hanger

As with many other projects, there’s plenty of room for the woodworker to show their personality and creativity in their design of a compression quilt hanger. Part of that creativity may be limited by whatever wood is available in the workshop or the local lumberyard. Most compression quilt hangers are made of hardwoods, as befits an heirloom collectible, but they can also be made of lower-cost softwood, especially molding.

If molding is to be used for the quilt hanger, it would be advisable to use either a patterned piece of molding, such as a wood strip one with a vine pattern stamped into it, or a chair rail. The casing and baseboard look just like what they do when used for projects of this type, making them a poor choice. But the big problem with molding is that it is no more than ½” thick, so more fasteners need to be used to hold the two halves of the hanger together so that the quilt won’t sag.

Ideally, two pieces of ¾” thick hardwood should be used to make the quilt hanger. Those pieces will provide enough stiffness, so fasteners only need to be used about every 16”. If ½” thick material is used, that should be closed up to about every 12”. Generally speaking, 2” wide boards are sufficient. They should be cut the same length, slightly longer than the side of the quilt they will hold.

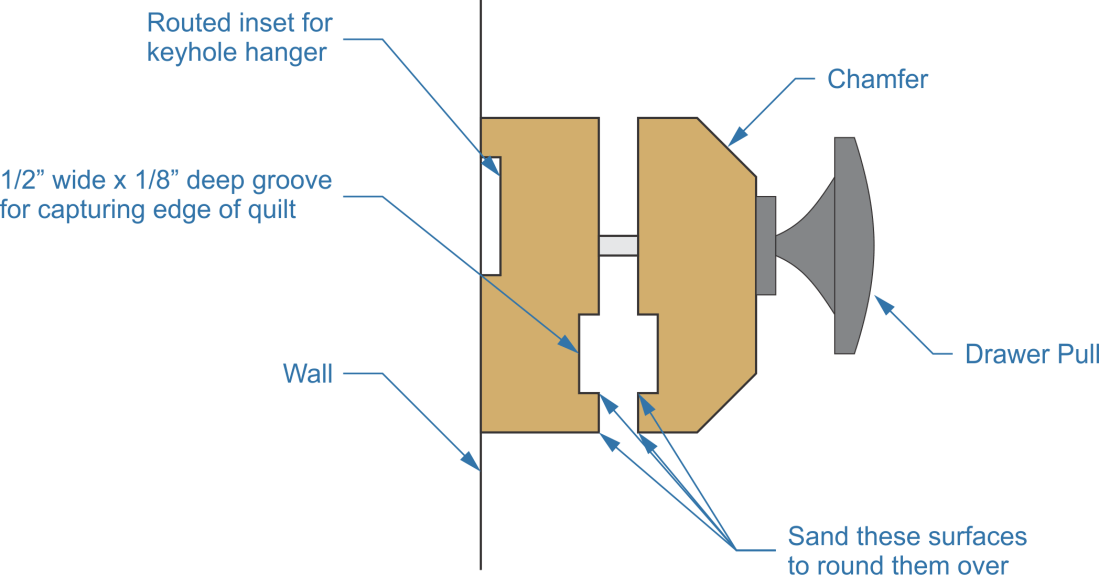

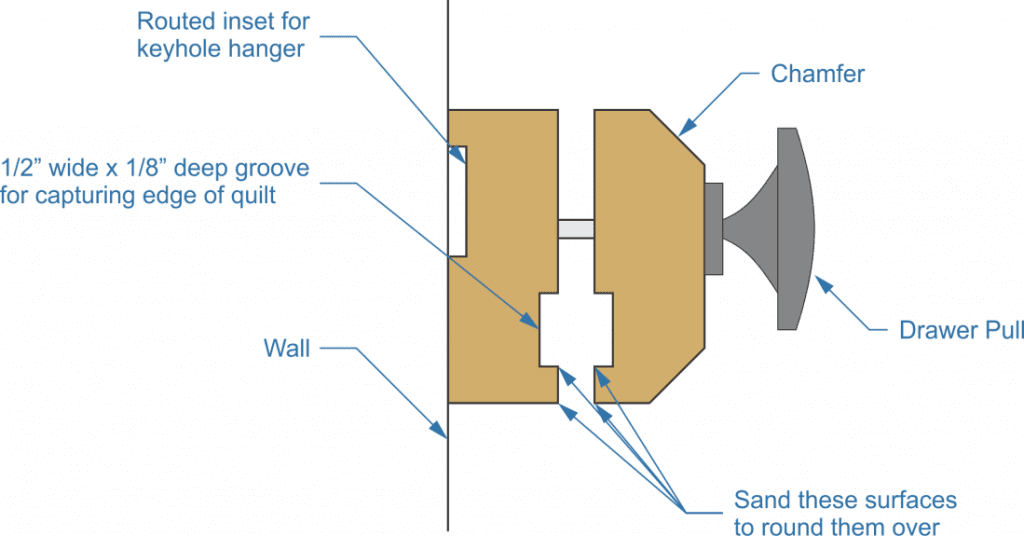

Rout a ½” wide, 1/8” deep groove along the entire length of both pieces, ¼” from what will be the bottom edge, when the quilt is hung. The faces this is routed into will become the mating faces of the boards. Sand the edges of the groove and the mating edges of the board to round them over and prevent chaffing of the fabric. Also, route recesses into the backs of the back piece to install keyhole fasteners into it.

The outer face of the front board can be cut with a router or on a router table to provide a more attractive profile if so desired. Depending on the desired look, a number of different bits would work for this. Some standard profile bits used might be chamfer, corner rounding, Roman ogee, corner rounding, or a combination of corner rounding & beading bit.

Rather than just screwing the two halves of the hanger together and having screw heads showing, it will look nicer to use round drawer pulls as the “nuts,” with the screws coming through from the back side of the clamp. To do this, align the two clamp pieces and tape them with the painter’s tape. Then mark the locations for the attached hardware. Drill through both pieces of wood together, preferably with a drill press, ensuring that the drill holes are perpendicular to the surface of the wood.

Take the tape off the two pieces and sand them smooth, staining and varnishing the pieces. Take care not to let sawdust get into the varnish while drying. Even so, it’s a good idea to lightly sand the surfaces between coats to remove any bumps caused by dust settling in the finish while it is drying.

A Magnetic Variant

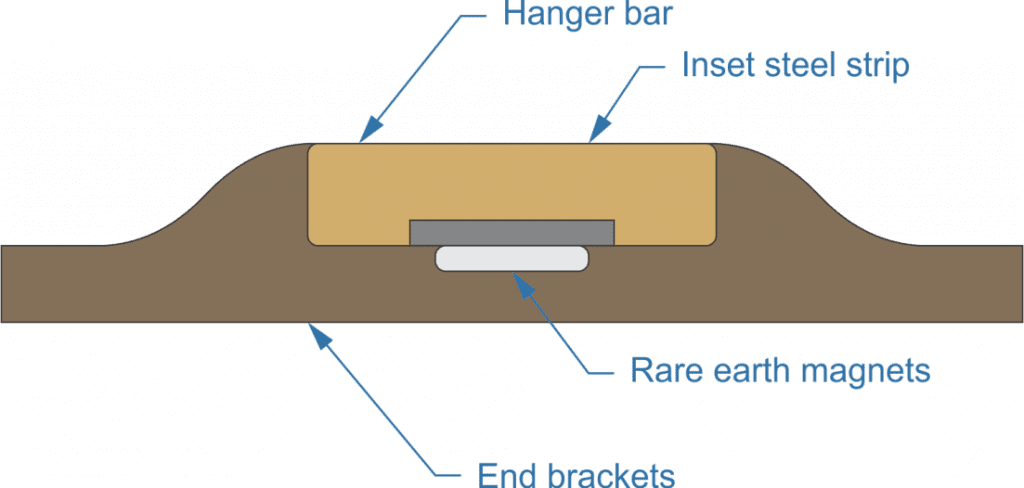

There is a magnetic variant of the compression quilt hanger on the market. It looks much like any other compression quilt hanger, except that perpendicular hanger pieces are attached to each end of the hanger bar. This allows ample space between the hanger bar and the wall, as there is no back bar, just the front one.

I question whether these can be called compression quilt hangers because they do not work as I described. The main difference in how they operate is that a metal strip is inset into the bar, and the quilt is held with rare earth magnets. While very effective, this hanger has the same potential to allow the quilt to sag between the screw, just like any other one that clamps onto the quilt in several separate locations.

Making such a hanger is pretty straightforward. All that’s needed is a piece of 1” thick hardwood, 2” wide and longer than the quilt is wide. Two mounting brackets for the ends are cut from matching hardwood to a profile shown in the diagram below (in brown). These will be attached to the ends of the hanger bar, either with dowels, mortise, and tenon or screws. They will each need two mounting holes, top, and bottom, or a keyhole mounting bracket inset into the back.

Before attaching the mounting brackets, rout out a 1” wide groove in the back side of the hanger bar, slightly less than 1/8” deep. Mount a 1” wide by 1/8” thick steel strip in this slot. To do so, I’d recommend drilling and countersinking a hole into the steel strip so that a flathead wood screw could be used to mount it. It’s a good idea to clean the steel with a degreaser and then paint it before mounting it to the hanger. Remember to use oil on the drill bit and countersink so that they don’t overheat while drilling the metal, as that will dull them.

To hang the quilt, the quilt hanger is laid on the table face down, and the quilt is laid on top of it, with the quilt’s binding strip just above the steel strip in the back of the hanger strip. Then place some 25mm square by 3mm thick rare earth magnets on the quilt, over the steel strip to hold it to it. Hang the quilt hanger on the wall.

Hanging the Quilt

To hang a quilt with the compression quilt hanger, it is first necessary to attach the hanger to the edge of the quilt. This is best done on a large table so that the part of the quilt attached to the hanger can be spread out.

Run the clamp screw through the back of the back piece of the wall hanger and then lay the back piece on the table, with the top edge near one side of the table. Then lay the quilt on the table, setting the edge binding of the quilt into the groove cut into the surface of the wood piece. Then select the front part of the clamp in place, running the screws through it as well and with the groove in that bar over the quilt’s edge binding. Tighten down the round drawer and pull “tightening screws,” clamping the quilt firmly between the two halves of the compression quilt hanger.

Install two screws into the wall, level with each other and the same distance apart as the two keyhole hangers on the back of the compression quilt hanger. Ideally, these screws should be going into studs in the wall. If they are not, then use molly bolts so that there is support and the screws don’t pull out. Remember, the screw heads should not be tightened down, so they can be captured in the keyhole hangers. Hang the quilt.