Redwood isn’t just a wood — it’s a symbol of natural beauty, longevity, and craftsmanship. From the towering coastal trees of California to the finely milled boards in your local lumber yard, redwood has a history and set of properties that make it stand out from almost every other building material.

I’ve worked with redwood on everything from outdoor decks to custom furniture. Every time I cut into a fresh board, I’m reminded why it’s so prized: it has a rich, reddish-brown color, a pleasant aroma, and an almost silky texture under a sharp plane. In this guide, we’ll cover everything you need to know about redwood, from its origins to its uses, grades, finishing techniques, and maintenance tips.

Why Redwood Is a Favorite for Builders

I’ve always thought redwood had a way of making simple projects look like they came straight out of a design magazine. That reddish color just pops, whether it’s a fence, a deck, or a garden bench. But the real reason I use it isn’t just looks — it’s tough. The high tannin content is like nature’s built-in protection. It keeps rot and bugs from moving in, and it even holds up better than you’d expect if there’s ever a fire nearby.

Another thing I appreciate is how clean it cuts. There’s hardly any resin in redwood, so my saw blades don’t end up coated with gunk halfway through a job. That saves me time, and my blades last longer.

Over the years, I’ve used it for all sorts of outdoor work:

- Decking that still looks good ten years later.

- Adirondack chairs that don’t get too hot in summer.

- Fences that shrug off rain and sun.

- Pergolas that add a warm, welcoming feel to the yard.

- It’s one of those woods that just behaves — and in my book, that’s worth paying for.

Redwood vs. Other Softwoods

Compared to pine or fir, redwood holds up far better in damp or humid conditions. Cedar is a close competitor, but it often wins on longevity and visual appeal. It also doesn’t require pressure treating, unlike many softwoods, which rely on chemical preservatives to prevent rot.

Understanding Redwood Grades

Redwood is graded by clarity, grain consistency, and the ratio of heartwood to sapwood. Heartwood—the deep-colored core of the tree—is more resistant to decay and typically used in premium applications.

Top Grades:

- Clear All Heart (CAH) – Pristine and all-heartwood.

- Heart Clear (CH) – Minor imperfections, but still heartwood.

- Heart B (HB) – Includes tight knots and variations.

Lower or Mixed Grades:

- Construction Heart – Functional and strong for framing.

- Deck Common – Budget-friendly for large builds.

- Merchantable – Lower grade, best for hidden structural work.

Redwood lumber has its grading system, which includes a variety of different grades:

| Architectural Heartwood Grades | |

| Clear All Heart (CAH) | Finest architectural heartwood, free of defects on at least one face. Generally comes surfaced and well-machined. Usually kiln dried. |

| Heart Clear (CH) | Similar to CAH but with limited imperfections allowed. Usually kiln dried and surfaced or saw-textured. |

| Heart B (HB) | Economy-grade redwood used for fences, retaining walls, and garden structures. Larger knotholes and imperfections are allowed, as well as splits and checks. |

| Architectural Sapwood Grades | |

| Clear | The same general quality as CH, but allowing sapwood. |

| B Grade | Similar to clear, but with limited imperfections and knots. |

| Garden Grade Heartwood | |

| Construction Heart | Similar in appearance and specifications to a construction heart, but also graded for strength. Deck heart is only available in 2×4 and 2×6 sizes. |

| Deck Heart | Economy-grade redwood is used for fences, retaining walls, and garden structures. Larger knotholes and imperfections are allowed, as well as splits and checks. |

| Merchantable Heart | Economy-grade redwood is used for fences, retaining walls, and garden structures. Larger knotholes and imperfections are allowed, as well as splits and checks. |

| Garden Grade Sapwood | |

| Construction Common | Essentially the same as Con Heart, with the addition of sapwood. Used for decks, fences, and above-ground garden uses. |

| Deck Common | Similar to Con Common, with the exception that it is graded for strength. Only available in 2×4 and 2×6 sizes. |

| Merchantable | Essentially equal to merchantable heart, with the addition of sapwood. |

For more wood grading clarity, read Plywood Grades Explained.

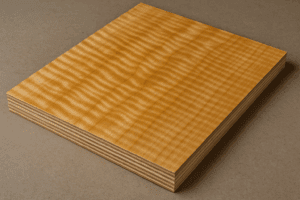

Redwood Lumber vs. Redwood Plywood

You won’t find much redwood plywood at your local home store—it’s mostly used in niche millwork and specialty orders. In contrast, solid redwood boards are available in many lengths and thicknesses. For decorative or load-bearing outdoor work, solid redwood performs better. If you’re comparing it to indoor-friendly panels, check out our list of Best Plywood for Cabinets.

Redwood from Other Regions

California redwood is iconic, but other countries grow it, too. New Zealand plantations produce it with wider growth rings and slightly less density. Still, it’s a sustainable and affordable choice. Just make sure you’re not buying “Scandinavian redwood”—a common term for treated pine that’s dyed red.

Is Pressure-Treated Redwood a Myth?

Mostly, yes. Real redwood doesn’t need pressure treatment. Its natural properties make it rot-resistant without added chemicals. If you see pressure-treated redwood advertised, it’s likely dyed pine.

Stick with heartwood and add sealant for additional moisture protection.

Useful protection products:

Tips for Working

Working with redwood has always been one of those jobs I look forward to. Whether I’m cutting, routing, or fastening, it’s just a nice wood to have on the bench. It’s smooth under the plane, smells good when you cut into it, and it behaves predictably — no wild grain tearing out for no reason. Still, I’ve learned a few tricks to keep it looking its best.

The first is keeping blades sharp. Redwood isn’t hard on tools, but dull blades will tear the grain instead of slicing it, especially around knots or on crosscuts. I keep an extra carbide-tipped blade on hand when I know I’m milling a lot of it.

Pre-drilling is another must, even though redwood is soft compared to oak or maple. It helps avoid splitting near the edges and keeps fasteners seated cleanly. When it comes to hardware, skip plain steel nails or screws. The tannins in redwood will react with iron and leave ugly black stains that are a pain to sand out later. Stainless steel, coated deck screws, or even high-quality brass hardware are worth the extra cost — especially on projects that are meant to last outdoors.

If you’re routing profiles, take lighter passes rather than hogging off too much at once. Redwood cuts cleanly, but big bites can leave chatter marks. For glue-ups, I use a waterproof wood glue like Titebond III on outdoor builds, and regular yellow glue for interior projects. Clamp pressure should be firm but not crushing — redwood’s softer fibers will compress if you overdo it, which can throw off your joinery.

Handled with care, redwood rewards you with a smooth finish, strong joints, and hardware that stays put for decades. It’s one of those materials that’s forgiving enough for beginners but still satisfying for experienced woodworkers.

Top tools and adhesives:

Redwood and the Environment

Modern redwood harvesting is eco-conscious. Most suppliers rely on replanted trees and follow strict sustainability practices. The FSC certification guarantees that your wood comes from responsibly managed forests that protect biodiversity and workers’ rights.

Where to Get Redwood

You can pick it up from:

Easy DIY Projects

If you’re just getting your feet wet with redwood, start small. A raised planter box is about as forgiving as it gets, and redwood doesn’t mind sitting up against damp soil for years. I put one together for my wife’s herb garden years back, and aside from a few nail heads working loose, it’s still standing. The same goes for compost bins — nothing fancy, just solid boards and room for air to flow.

Once you’ve got a feel for it, redwood’s easy nature makes bigger jobs less intimidating. I built a freestanding pergola for a neighbor’s patio, and the straight grain made all my angled cuts land perfectly. No wrestling with warped boards, no surprise tear-out. If you’re feeling bold, a custom outdoor sectional is a great way to show off what redwood can do — plus, it’s a lot more comfortable than a row of folding chairs.

If your project’s headed outdoors, a few habits make all the difference. Seal the ends of every fresh cut — I keep a little jar of sealer open while I work so I don’t “forget it for later.” Get the wood off the dirt with stone pads or metal feet. And if you want that rich, red tone to last, go with a penetrating oil that has UV protection. I give mine a touch-up every other summer; otherwise, it will fade into that classic silvery gray that some folks prefer.

Caring for Redwood

One of the nice things about redwood is that it doesn’t nag you with constant upkeep. I usually give mine a light cleaning twice a year — once in spring and once in late fall — using nothing more than mild soap, a bucket of warm water, and a soft-bristle brush. No pressure washers, no harsh chemicals. That’s all it needs to keep dirt and pollen from settling in.

If it’s a surface that sees a lot of use — like a deck, table, or bench — I’ll re-oil or reseal it once a year. This helps maintain that deep, rich red tone. If you’re after the natural, weathered look, just let it be, and it will fade gracefully to a silvery gray.

For outdoor furniture, I either move it into the garage during winter or cover it with a breathable fabric. Plastic tarps trap moisture, which can do more harm than good. A little protection goes a long way toward making your redwood projects last decades.

Bringing It Indoors

Redwood isn’t just for decks and pergolas — it can make a serious statement indoors, too. I’ve seen it used as a feature wall in a living room, where the warm tones instantly became the focal point. Exposed ceiling beams in redwood add a rustic, yet refined touch, and a fireplace surround in rich, clear heartwood feels both natural and high-end.

For furniture, I like using it in ways that let the grain and color shine without subjecting it to daily abuse. Shelving, bed headboards, and decorative trim are all perfect candidates. Because redwood is softer than hardwoods like oak or maple, it’s not the best choice for a dining table or kitchen countertop that will see constant wear and tear.

Indoors, a clear finish does more than make it look good — it seals in that beautiful reddish hue and adds a layer of protection against scuffs. I usually go with a satin or matte sheen to keep it looking warm and natural rather than overly glossy.

Final Thoughts

Redwood has that rare mix of natural beauty and toughness that makes it hard to pass up. I’ve used it on jobs for clients and on my weekend builds, and in both cases, it’s been worth it. The color alone — that deep, warm red — makes people stop and ask what kind of wood it is. You don’t get that same richness from a stain over pine or fir.

It isn’t cheap, and I won’t pretend otherwise. But I’d rather spend a little more once than keep replacing warped boards or sanding down rough spots every couple of summers. A redwood bench I built for my folks is still rock solid after eight years outside, with only an occasional rinse and a fresh coat of oil. In my book, that kind of lifespan pays for itself, and then some.