Name plates are more than just labels — they’re subtle symbols of professionalism, pride, and identity. Whether it’s hanging outside an office door or sitting neatly on a desk, a wooden name plate adds a touch of class that plastic or metal simply can’t replicate.

There are two common types of wooden name plates:

- Flat name plates: Ideal for walls, doors, or conference tables.

- Angled desk name plates: Designed with a tilted face for easy reading from any position.

Each type offers nearly limitless possibilities for customization — from simple engraving to detailed carving — making wooden name plates perfect for professional offices, weddings, awards, and even home décor.

Why Choose Wood for Your Name Plate?

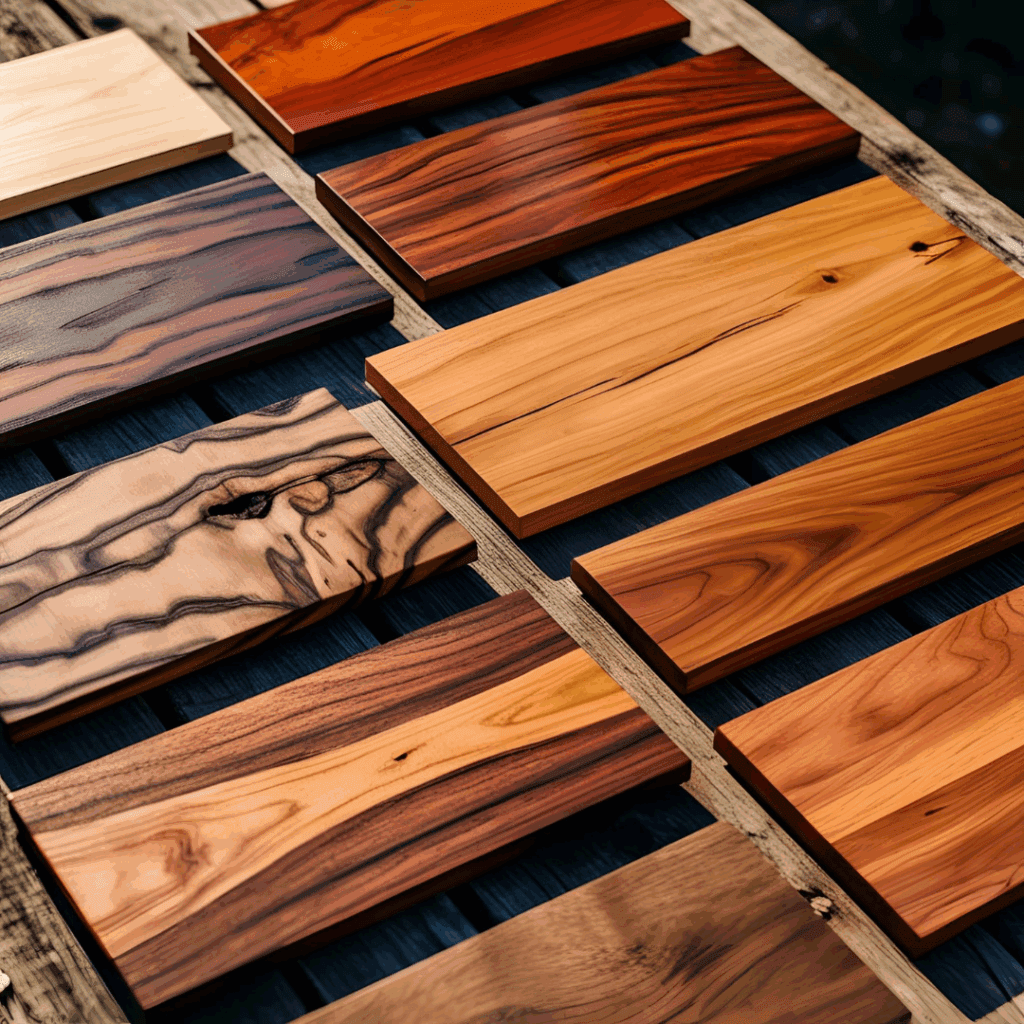

While plastic or metal name plates have their place, wood remains the favorite choice for people seeking elegance and longevity.

Here’s why wood stands out:

- Durability: Hardwoods like walnut and oak resist dents and scratches.

- Aesthetic: The natural grain patterns add richness and texture.

- Versatility: Easy to carve, engrave, stain, or paint.

Natural wood surfaces are becoming increasingly popular in modern interior design.

If you’re building your own, starting with a premium unfinished cherry board from Amazon gives you a strong, beautiful foundation that’s ready for your creative touch.

Designing Your Name Plate

Before you even pick up a saw, sketch out your design. Ask yourself:

- Will it be hung on a wall or sit on a desk?

- Do you want a simple rectangle or a unique shape?

- Will you add carvings, logos, or other designs?

Good planning ensures you won’t have to redo cuts later, especially if you’re working with expensive hardwood.

How to Cut and Shape a Wooden Name Plate

Cutting Flat Name Plates

Flat name plates are simple — usually a clean rectangle.

Use a miter saw or band saw to cut your blank to size. Thinner stock, like ¼-inch or ½-inch wood, is perfect for name plates and can be found at most home improvement stores.

If you’re planning a decorative outline (curves, waves, or intricate edges), a scroll saw is ideal. I recommend the DeWalt Scroll Saw (Amazon) for precise, easy cuts.

Pro tip: Always sand your blank after cutting! Smooth surfaces make carving, engraving, and finishing far easier.

Cutting Angled Desk Name Plates

If you’re making an angled desk plate:

- Start by squaring the blank.

- Tilt your table saw blade between 30° and 45°.

- Carefully cut the bevel.

Blade marks are inevitable — plane or sand them out for a clean, flawless face.

To soften the edges:

- Use a router with a round-over bit.

- Round only the top and sides. Leave the bottom edge sharp for desk stability.

How to Add Lettering

This is where your name plate truly comes alive!

You have four excellent options for lettering:

1. Brass Plates

A classic method: order a custom-engraved brass plate online and glue it onto the wood.

Gorilla Wood Glue (buy it here) works beautifully to bond brass to wood permanently.

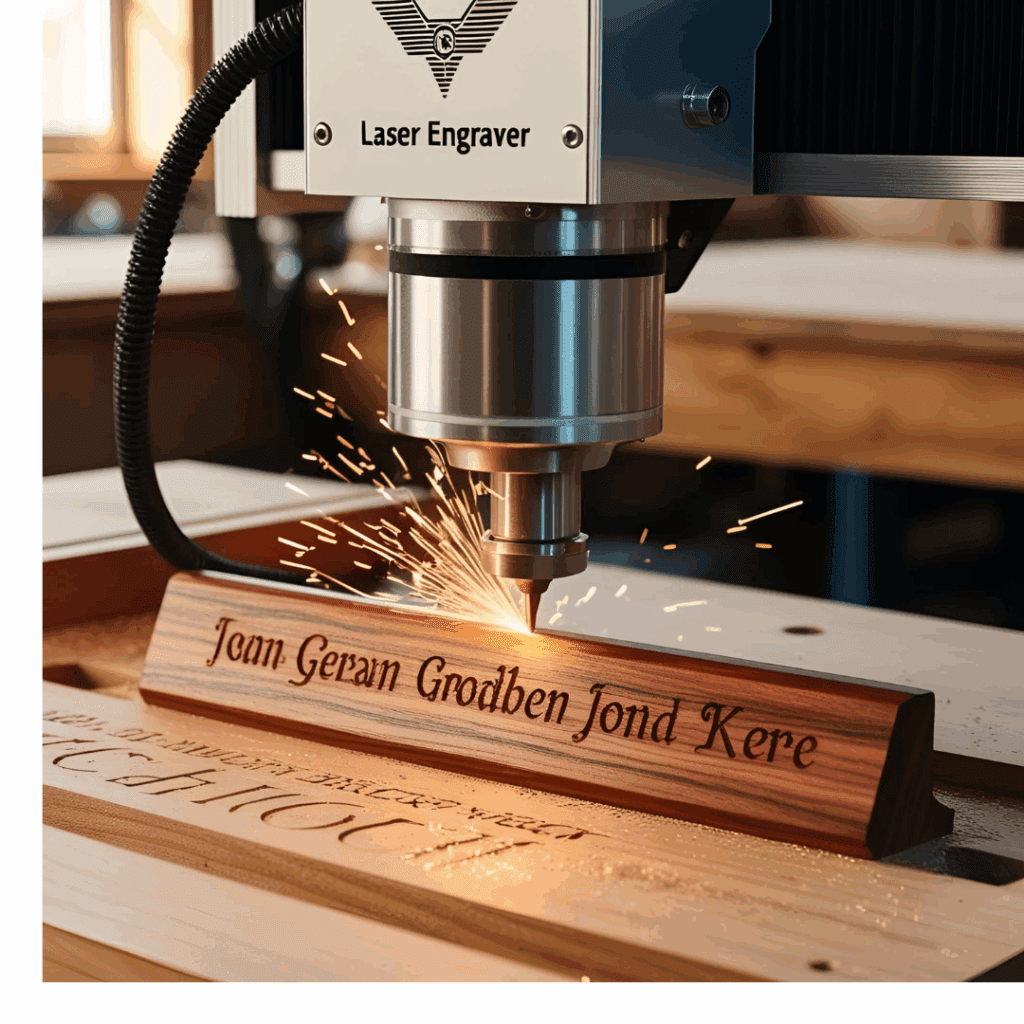

2. Laser Engraving

Laser engraving is clean, modern, and ultra-precise.

Affordable desktop engravers like the xTool D1 Pro (Amazon) make it easy to personalize your name plate at home — adding names, logos, or fancy monograms.

3. Hand Carving

If you have a steady hand (and patience!), hand-carving letters with wood carving tools offers a stunning, old-world effect.

If you’re new to carving, start with a letter template kit (Amazon) to help guide your cuts.

4. Wood Letter Appliqués

For a bold 3D look, scroll-saw your name from thin wood and glue the letters onto the plate.

Or, if you prefer, you can buy pre-cut wooden letters and customize from there.

Decorating and Finishing Touches

Beyond the name, decorating your plate can make it a true piece of art.

Options include:

- Carved borders – vines, floral designs, or geometric patterns

- Appliqués – insignia, logos, or badges

- Paint and stain – create contrast between the name and the background

Before adding decorations, apply a protective finish like General Finishes Arm-R-Seal (Amazon) for long-lasting beauty.

Tip: Finish the blank first, then add appliqués. It’s much harder to work around glued-on decorations!

Displaying Your Name Plate

Finally, proudly display your name plate!

For wall-mounted plates:

- Use Command Strips for a clean, no-damage install.

For desk plates:

- Simply place on your desk, shelf, or podium.

- Or package it in a wooden display box for a professional gift presentation.

How to Personalize Your Name Plate Even Further

Beyond carving names or applying appliqué letters, there are even more ways to make your wooden name plate truly one-of-a-kind. Personal touches not only enhance its visual appeal but also make it more meaningful as a personal item or gift.

Adding a Logo or Emblem

If you’re making a name plate for a company, military branch, university, or organization, consider adding a small logo beside the name.

You can:

- Laser engrave the logo directly onto the wood.

- Paint a hand-detailed logo using fine-tip paint pens (Amazon).

- Use a vinyl decal applied with a transfer sheet.

Tip: Keep logos subtle and proportional to the name to maintain a clean, professional look.

Using Color Accents

While natural wood tones are beautiful, adding a splash of color can make your name plate stand out even more.

Ideas include:

- Painted backgrounds behind carved letters.

- Metallic gold or silver paint inside engraved letters.

- Contrasting stains — dark stain around the border with a lighter center.

A high-quality artist’s paintbrush set (Amazon) is ideal for fine detail work.

Adding Hardware for a Finished Look

Tiny details make a big difference. Consider adding:

- Corner brackets (brass or antique style)

- Leather hanging cords for wall plates

- Tiny protective rubber feet under the desk plates

Not only does this give your name plate a finished, luxury feel, it also protects the wood from scuffing over time.

Creating a Matching Set

If you’re making one name plate, why stop there?

You could create an entire coordinated office set:

- Desk name plate

- Door sign

- Desk organizer

- Business card holder

All made from the same wood species and stained to match.

This is especially impressive for law firms, startups, and high-end offices.

Personalizing your wooden name plate elevates it from a simple identifier to a true piece of craftsmanship — something that speaks volumes about your attention to detail and style.

Conclusion: Your Signature Statement

A wooden name plate combines craftsmanship, identity, and elegance all in one.

Whether you carve, engrave, or appliqué your design, the result is a timeless piece that reflects your personality and pride.

Building a custom wooden name plate isn’t just a project — it’s a personal signature. And once you complete it, it will hold meaning far beyond the grain of the wood.