Let’s not sugarcoat it — I avoided building drawer boxes for way too long. They always seemed like a pain: too many precise cuts, too much room for error. I figured one wrong measurement and the whole drawer would end up wonky. But I was wrong — drawer boxes aren’t nearly as scary as they look.

Once I got the hang of it (and messed up a few along the way), building drawer boxes became something I enjoyed. Whether you’re tackling your first drawer or trying to streamline the process, this is the no-nonsense guide I wish I had when I started.

Why Drawer Boxes Seem Like a Big Deal (But Really Aren’t)

I get why people shy away from drawer boxes. You need precise sizing, repeatable cuts, and a clean look — and let’s be honest, most of us just want to build the cabinet and be done with it.

But drawer boxes don’t have to be a stressful part of the job. Once you understand how they go together, it’s just measuring, cutting, and gluing — like any other woodworking task. The hardest part is just building the first one.

Drawer Box vs. Drawer Front — Big Difference

Early on, I assumed the front of the drawer was part of the box. It’s not — and separating the two in your mind makes everything easier.

The drawer box is the guts: four sides and a bottom. The drawer front is the finished face you see. And most of the time, the front is attached after the box is installed, especially with overlay-style cabinets.

Pro tip: If you’re remodeling your kitchen, you can even order your drawer fronts to match your cabinet doors and just build the boxes yourself.

Related post: How to Build DIY Cabinets

Want to Skip the Measuring? Use a Drawer Box Kit

I’ve used drawer box kits when I’m short on time — and they’re honestly a great option. You get the four sides and bottom cut for you, and you just assemble it. Some even include a matching front.

The cheap kits are a no-go though — if they’ve got a flimsy masonite bottom, I skip ’em. Look for:

- 1/2″ plywood bottoms

- Good-quality hardwood sides

- Dovetail or notched joints if you want strength and looks

Amazon Picks:

Building Drawer Boxes From Scratch (Step-by-Step, No Stress)

When I make drawer boxes from scratch, here’s how I do it:

- Two sides

- A front and back

- A bottom — either inset or glued to the underside

I typically use 1/2″ birch plywood for clean projects, or BC plywood if I’m working on a garage or shop cabinet.

Sizing Tips:

- Make the width 1″ less than the cabinet opening (for slides)

- Make the height 1″ shorter than the drawer opening

- Standard depth is around 20–22″

Most 1/2″ plywood isn’t actually 1/2″ — it’s usually closer to 15/32″, so measure before cutting your bottom panel.

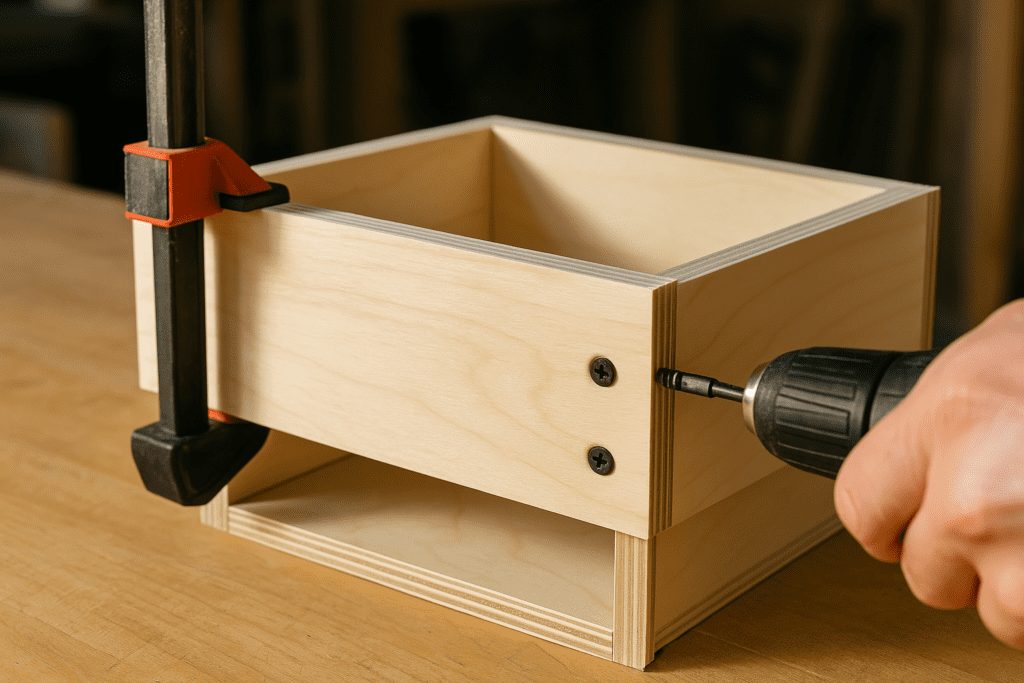

How I Put Mine Together:

- Glue and brad nail the front to the bottom

- Attach the sides

- Add the back last

- Square it up, clamp it, let it dry

Tools I Always Reach For:

Want a Stronger Box? Inset the Bottom

If the drawer is going to hold tools, pots, or anything heavy — inset the bottom.

I cut a 1/4″ groove into each side panel using a dado blade. The groove sits about 3/8″ from the bottom edge and lets the plywood bottom slide into place before the box is glued.

You’ll need to increase the size of your bottom panel slightly — usually about 3/8″ longer and wider than usual.

Related post: Types of Plywood and Their Uses

Installing the Drawer Front (Without the Guesswork)

Here’s how I do it:

- Put the drawer box on a spacer (I use scrap wood about 1/2″ thick)

- Set the drawer front in place and line it up

- Screw it in from the inside

- Install the pull to help hold it tight

Skip the glue — if you ever need to adjust or replace the front later, you’ll be glad you did.

Fancy Joinery? Optional. But Pretty Cool.

If I’m building shop cabinets, I go simple. But when I want drawers to look sharp — like for furniture or fine cabinetry — I’ll use dovetails or finger joints.

Dovetail Drawer Boxes

- Timeless and strong

- Requires a jig and a router

- Test on scrap first to dial it in

Amazon Pick: Dovetail Jig for Routers

Finger Joint Drawer Boxes

- Easier to make

- Still strong and clean

- Use a dado blade and a spacing jig

Amazon Pick: Dado Blade Set for Table Saw

Things I Had to Learn the Hard Way

- Label every scrap you cut — seriously

- Always do a dry fit

- Cheap drawer slides work fine if you install them right (I overpaid for years!)

Final Thoughts on Drawer Boxes

If you’re putting off a project because of the drawers — just go for it. Start with a small one. Or a drawer box kit. Doesn’t matter.

Once you’ve built a couple, you’ll wonder why you avoided them in the first place. I sure did.