Sapele plywood is a premium hardwood plywood known for its strength, beauty, and versatility. If you’re searching for an exotic wood product that performs well in demanding applications—both indoors and out—Sapele plywood might be exactly what you need. Often compared to mahogany, this African hardwood offers greater hardness, distinctive grain patterns, and a reddish-brown tone that ages gracefully.

Whether you’re building a boat, crafting musical instruments, or creating custom furniture, Sapele has become a top choice for professionals and hobbyists alike.

🌍 What Is Sapele Wood?

Sapele (pronounced sah-PEL-ee) comes from the Entandrophragma cylindricum tree, a towering species native to tropical regions of Africa, including Sierra Leone, Uganda, and Angola. These trees grow up to 180 feet tall and have trunks reaching 7 feet in diameter, making them one of the dominant canopy trees of African rainforests.

The wood itself is dense, durable, and has an interlocking or wavy grain with occasional cross-grain patterns. Its heartwood ranges from medium to dark reddish brown and may display ribbon-like figures or shimmer under light—a trait that enhances its visual appeal.

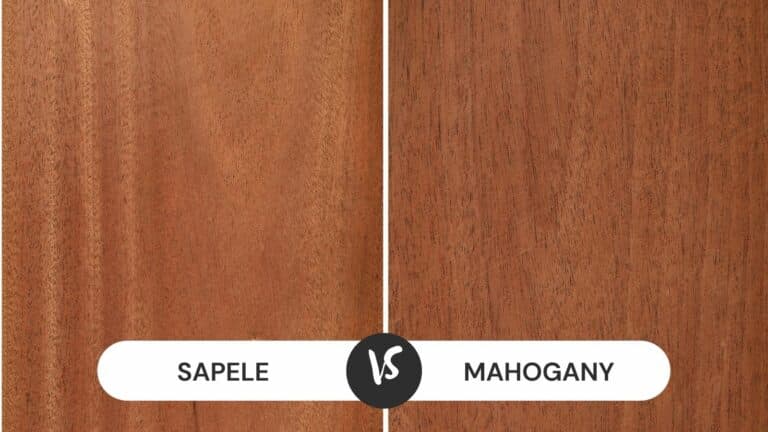

🔚 Sapele vs. Mahogany: What’s the Difference?

Many woodworkers refer to Sapele as “African Mahogany,” and visually, they do share similarities. However, Sapele is:

- Harder and denser than both African and Honduran mahogany

- More resistant to denting, shock, and bending stress

- Stronger under load, comparable to white oak

- Less prone to warping in outdoor environments when sealed

🪕 Unique Characteristics of Sapele Wood

One thing that makes Sapele wood distinct is its natural aging process. If left untreated, Sapele will gradually turn silver-gray, similar to teak. This aesthetic aging doesn’t affect the wood’s integrity, strength, or size, but it can be desirable—or undesirable—depending on your project.

- 🟢 Desirable: For weathered outdoor designs like boat trim or patio seating

- 🔴 Undesirable: For glossy interior projects—use a UV-protective finish to preserve color

Sapele’s interlocked grain can be challenging to plane, but it accepts finishes, stains, and varnishes exceptionally well.

🛠️ Common Uses for Sapele Wood and Plywood

🚤 Marine Applications

Sapele plywood is widely used in boat building, particularly for decorative and structural trim like:

- Rub rails

- Gunwales

- Coamings

- Deck trim and hatches

It’s important to avoid knots in marine applications since water intrusion around them can lead to failure over time.

🎸 Musical Instruments

Sapele has become a favorite among luthiers (guitar builders), often as a sustainable alternative to mahogany:

- Back, sides, and necks of acoustic guitars

- Electric and acoustic-electric guitar bodies

- Ukuleles and mandolins

Its hardness enhances treble tones and provides better sustain, great for crisp, clear sound.

🧱 Furniture and Cabinetry

The attractive grain and durability of Sapele plywood make it ideal for furniture, particularly:

- Coffee tables

- Dining sets

- Dressers

- Accent cabinets

- Drawer fronts

The strength-to-weight ratio makes Sapele a great choice for fine furniture that must hold substantial weight without sagging or cracking.

🏡 Architectural and Flooring Projects

In architecture, Sapele is often used for:

- Decorative doors

- Hardwood flooring

- Wall paneling

- Crown molding

- Stair treads

Proper sealing can be installed outdoors, but it needs protection from UV and moisture to avoid graying.

📦 What to Know About Sapele Plywood

Sapele plywood is manufactured with thin outer veneers of Sapele and a stable inner core (often birch, poplar, or hardwood composite). These thin Sapele face layers are purely aesthetic, so avoid over-sanding, which can easily remove the beautiful grain layer.

✅ Key Features:

- Available in ¼”, ½”, and ¾” thicknesses (also 5.2mm metric panels)

- Commonly called “Sapele Mahogany Plywood”

- Core made from multi-ply hardwood for stability

- Compatible with marine-grade finishes

Link to your guide on Plywood Thickness and Uses

💲 Where to Buy Sapele Plywood

You’re unlikely to find Sapele plywood at your average hardware store. It’s more common at:

- Hardwood specialty suppliers

- Marine plywood dealers

- High-end online plywood retailers

If you’re working on a large project, it’s often better to custom-order a bulk supply. This lowers the cost per sheet and avoids issues with availability.

💡 Buying Tip:

When ordering online, shipping costs can be steep. Try to bundle your plywood order with other materials or coordinate with a local trim shop doing a larger shipment.

🛡️ Working With Sapele Plywood

Like other hardwood plywoods, Sapele can be tricky if you’re not prepared. Here are a few tips for working with it:

- Use sharp blades and bits to avoid tear-out

- Pre-drill screw holes to prevent splitting

- Apply a sanding sealer before staining for even absorption

- Avoid aggressive sanding to preserve the face veneer

🧰 Best Uses for Sapele Plywood in DIY Projects

If you’re a DIYer, Sapele plywood brings a high-end look without the extreme cost of exotic hardwoods. Consider using it for:

- Custom speaker boxes

- Media consoles

- Built-in bookshelves

- Home bar panels

- Heirloom keepsake boxes

🔍 Sapele Plywood and Sustainability: What You Should Know Before You Buy

One thing a lot of woodworkers don’t always consider, at least early on, is where the wood they’re using actually comes from. That was me a few years back. I was just focused on whether it looked good, held up well, and didn’t break the bank. But once I started working with imported hardwoods like sapele, I started asking better questions. Questions like: Is this stuff sustainably harvested? Is it a responsible choice?

Sapele comes from some of the larger canopy trees in West and Central Africa, and because it’s such a dense, attractive wood, it’s been harvested quite a bit over the years. But here’s the good news—nowadays, there’s a strong push toward responsible forestry, and more suppliers are offering FSC-certified sapele plywood. If you’re not familiar with FSC, that’s the Forest Stewardship Council. They keep tabs on whether a wood source is being managed in a way that doesn’t wreck the surrounding ecosystem or encourage illegal logging.

If you’re trying to be more conscious with your building materials, asking your supplier if their sapele is certified is a great place to start. You’ll usually find that FSC plywood might cost just a bit more, but the peace of mind is worth it, especially if you’re working on a project for a client or business that values sustainability.

Another angle people don’t talk about enough is that plywood itself is more efficient than using solid hardwood. Think about it: a single sapele log can yield way more veneer for plywood than it could for solid boards. So if you’re making furniture or cabinets and want that rich sapele look, plywood is a smart option. It makes better use of the tree and reduces waste while still giving you that bold color and interlocking grain that people love.

I’ve also noticed that sapele lasts. I used some leftover sapele ply for an outdoor bench project a few years ago. I sealed it well and expected to replace it in a season or two. It’s still holding up through rain, snow, and New York summers. The color did shift toward gray over time, which honestly gave it a weathered look that some folks love. You can prevent that change with a UV-protective topcoat if you prefer to keep the reddish-brown color.

One last tip: if you want to keep your sapele project low-impact from start to finish, try using water-based or low-VOC finishes. I’ve had good luck with brands like General Finishes and Rubio Monocoat. They keep the workspace breathable and still let that beautiful grain show through.

In short, if you’re after hardwood that’s tough, attractive, and capable of being sourced responsibly, sapele plywood checks all the boxes. Just do your homework on the supplier and take a little extra care in how you finish it, and you’ll end up with a project that not only looks incredible but feels good to stand behind.