Whether you’re building a cabinet, designing wall panels, or installing subflooring, choosing the right type of wood product is essential. Two popular options, plywood and hardboard, may seem similar at first glance, but they serve very different purposes. This guide offers a detailed comparison of plywood vs hardboard, helping you choose the right material for your next woodworking or construction project.

What Is Plywood?

Plywood is a manufactured wood product made by gluing together multiple layers (or “plies”) of wood veneer. These layers are arranged so the grain of each layer runs perpendicular to the one below, giving the sheet added strength and reducing the risk of warping.

Key Features of Plywood:

- Available in various grades and thicknesses

- High structural strength

- Good water resistance (especially marine-grade)

- Holds nails and screws well

Buy Birch Plywood Sheets on Amazon

What Is Hardboard?

Hardboard, or high-density fiberboard (HDF), is an engineered product made from exploded wood fibers that are compressed under high pressure. It has a hard, smooth surface on one side and a textured mesh backing on the other.

Key Features of Hardboard:

- Denser and heavier than plywood

- Extremely smooth surface (ideal for painting or laminating)

- Not naturally water-resistant unless tempered

- Not suitable for structural applications

Buy Tempered Hardboard Panel on Amazon

Applications: When to Use Plywood or Hardboard

Plywood Is Best For:

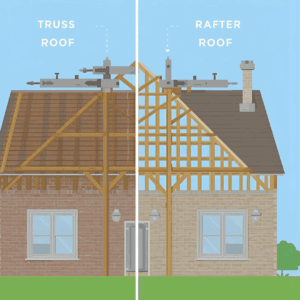

- Subflooring and sheathing

- Cabinet construction

- Roof panels and sheds

- DIY furniture frames

- Outdoor projects (marine-grade)

Hardboard Is Best For:

- Cabinet backing and drawer bottoms

- Interior wall paneling

- Furniture overlays

- Pegboards and flooring underlayment

- Templates and shop jigs

Durability and Strength

Plywood offers excellent structural strength and is flexible enough to resist cracking under stress. It’s better for holding screws, nails, and hardware.

Hardboard is denser and has better surface strength for impacts, but it’s brittle and doesn’t flex well. It can’t be used for load-bearing applications. Few materials are considered more potent than hardboard. However, it depends on the use of the material.

HDF is not flexible, so it only responds well to even pressure rather than direct impact. Plywood and MDF have a high degree of flexibility, which makes them better suited for subfloors, sheathing, and cabinets.

Moisture Resistance

Plywood, especially exterior or marine-grade, is more water-resistant than hardboard. Hardboard can swell if exposed to moisture, especially along cut edges. Tempered hardboard offers slightly more resistance but is still not ideal outdoors.

Recommendation: Use plywood in areas with moisture exposure (e.g., kitchens, basements, or outdoor structures).

Check Out Marine-Grade Plywood Options on Amazon

Workability and Appearance

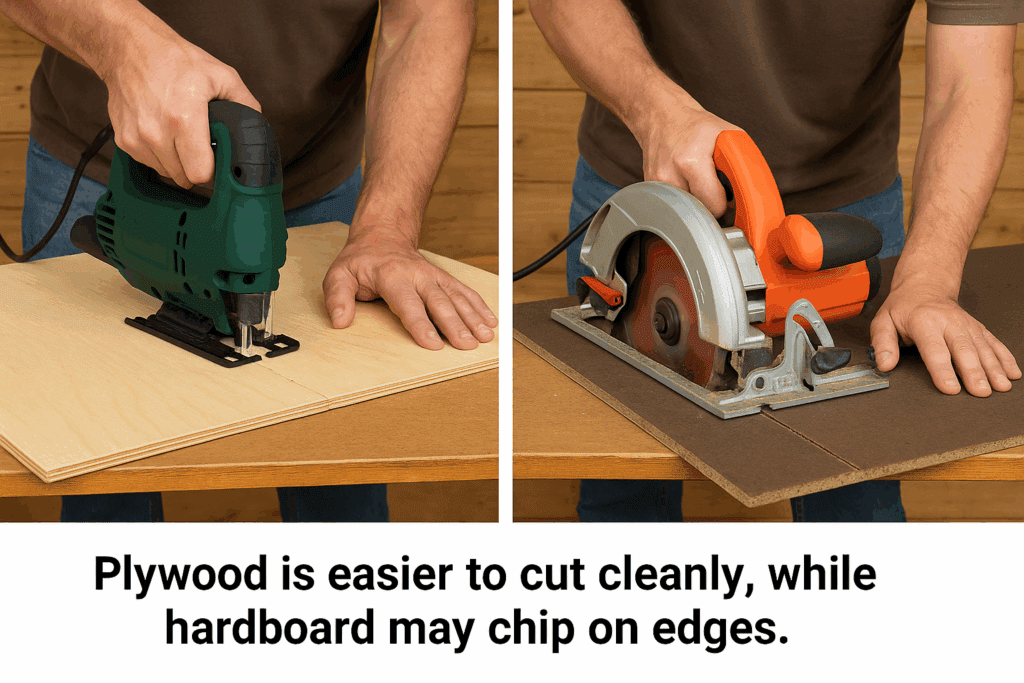

Plywood is easier to work with using standard woodworking tools. It can be sanded, painted, or stained easily.

Hardboard has a slick surface that’s ideal for painting, but can chip along the edges. Pre-drilling is often needed before attaching hardware.

Cost Comparison

| Material | Average Price (4×8 Sheet) | Best For |

|---|---|---|

| Standard Plywood | $12 – $55 | Framing, cabinets, DIY furniture |

| High-Grade Plywood | $60 – $120 | Exterior or marine uses |

| Hardboard (HDF) | $15 – $25 | Panels, flooring, cabinet backs |

Hardboard costs more per pound due to its density, but may be cheaper per sheet depending on thickness and grade.

Hardboard vs MDF

While MDF and hardboard are made using similar processes, hardboard is denser and stronger. MDF is more flexible and often preferred for intricate cuts or curves. Hardboard excels in flat, high-impact surfaces.

Sustainability and Environmental Impact

When choosing between plywood and hardboard, consider their environmental impact. Plywood often comes from sustainably managed forests and can be certified by organizations like the Forest Stewardship Council (FSC). It’s also reusable and recyclable in many cases.

Hardboard, being made from wood fibers and byproducts, makes efficient use of leftover materials, but the manufacturing process can involve significant energy usage. Additionally, the resins and bonding agents used in hardboard production may contain formaldehyde, depending on the product and brand.

For eco-conscious builders, opt for low-VOC plywood or formaldehyde-free hardboard. Always check for environmental certifications on the label to ensure responsible sourcing and manufacturing.

Installation Tips and Tools

Installing plywood or hardboard effectively depends on using the right tools and techniques. For plywood, standard power tools like circular saws, brad nailers, and wood screws will suffice. Always cut with the grain when possible and sand edges for clean finishes.

Hardboard requires a bit more care. Pre-drill holes to avoid splitting, especially when working near the edges. Use clamps to keep the board steady while cutting and avoid forcing screws directly into the surface without pilot holes. For painted finishes, always prime hardboard before applying latex or oil-based paint.

Recommended tools for both materials include:

- Circular saw or table saw

- Carpenter square

- Brad nailer or countersink drill bit

- High-quality wood primer (for hardboard)

Check Out the Kreg Rip-Cut Saw Guide on Amazon

Summary: Hardboard vs Plywood Comparison Chart

| Feature | Plywood | Hardboard |

| Structure | Layered wood veneers | Compressed wood fibers |

| Strength | High flexibility, holds fasteners well | High density, brittle under pressure |

| Water Resistance | Moderate to excellent (marine-grade) | Poor unless tempered |

| Appearance | Woodgrain, suitable for stain or paint | Smooth/glossy one side, paint-ready |

| Indoor/Outdoor | Both (with proper grade) | Indoor only |

| Best For | Cabinets, subfloors, roofing, sheathing | Both (with a proper grade) |

| Cost | $12–$120 | $15–$25 |

Final Thoughts: Which Should You Choose?

The answer depends on your project needs:

- Choose plywood for strength, water resistance, and structural applications.

- Choose hardboard for smooth indoor panels, underlayment, or templates.

Having both materials on hand can cover almost every DIY scenario. For outdoor work and durability, plywood is the winner. For crisp finishes and thin, dense panels, hardboard.