The first time I walked into a real lumberyard, I thought all the stacks of plywood looked the same. Big sheets, heavy, and ready to be cut down. I didn’t pay much attention—grabbed what was cheapest and figured I was being smart.

That came back to bite me. I spent a whole weekend putting together some garage shelves, proud of myself for saving money. A few weeks later, those panels started to bow and bubble. The shelves leaned, the edges curled, and I realized fast that not all plywood is created equal.

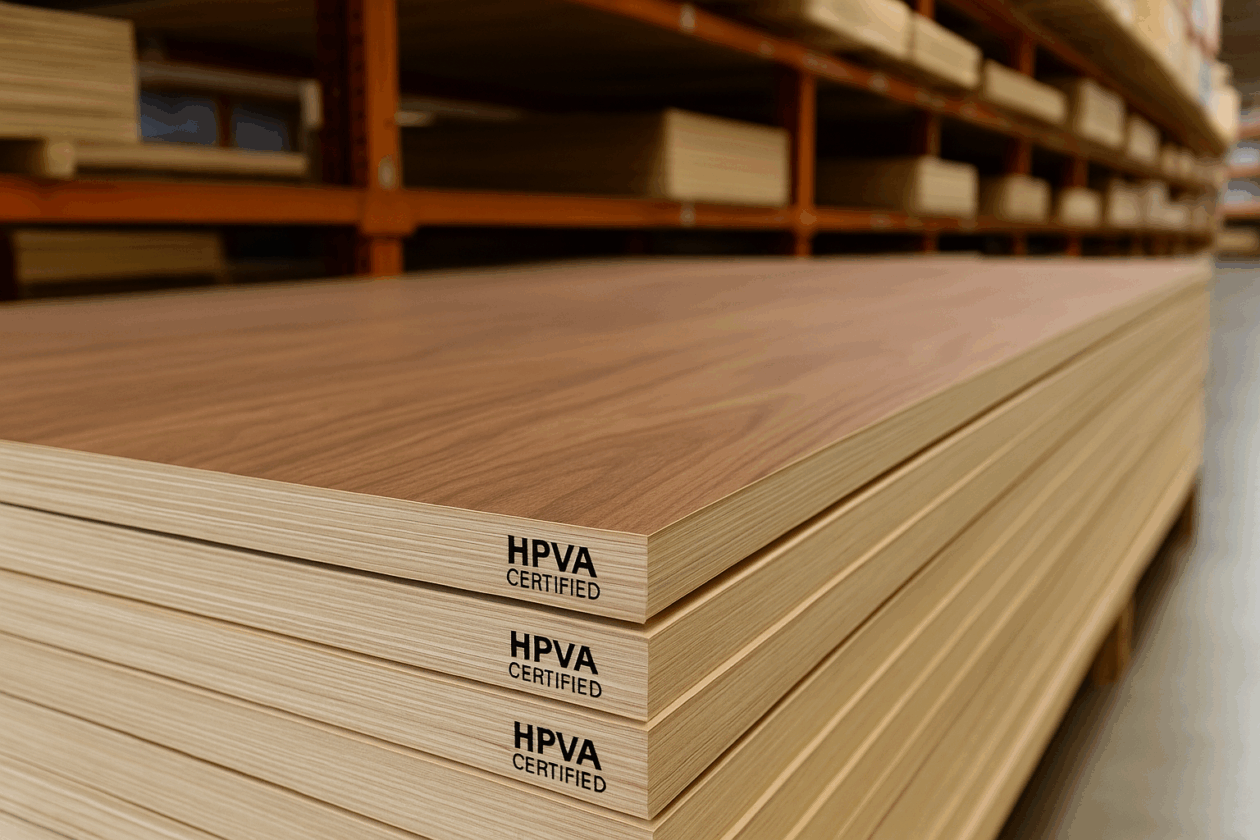

These days, when I’m building something that matters—kitchen cabinets, a bookshelf, even a closet door—I don’t mess around. I go straight for HPVA plywood. Certified by the Hardwood Plywood & Veneer Association, it isn’t just another panel off the rack. It’s tougher, more consistent, and built for projects where looks and strength both count.

So let’s dig in. I’ll walk you through what HPVA plywood is, why the certification stamp matters, and what to watch for when you’re picking out sheets at the yard.

What Is HPVA Plywood?

HPVA stands for the Hardwood Plywood & Veneer Association, now part of APA – The Engineered Wood Association. When you see “HPVA certified plywood” stamped on a panel, it means that the sheet meets the ANSI/HPVA HP-1 standard. That’s a strict quality checklist that covers everything from veneer appearance to adhesive emissions.

Over the years, I’ve noticed a clear difference between certified and uncertified sheets. Certified plywood tends to:

- Cut cleaner – less tear-out on the veneer.

- Stay flatter – you don’t get those frustrating bows or twists.

- Stain evenly – blotches are far less common.

- Last longer – cores hold together, instead of bubbling or separating.

Put simply, HPVA plywood gives you peace of mind. You know the panel you’re working with has already passed a standard that cheaper sheets often fail.

Why Certification Matters

You might be wondering—why pay extra for certification? I asked myself the same question until I built a set of maple shelves using off-brand “cabinet grade” plywood. The veneers were full of patches, and once I applied stain, the color looked blotchy and cheap. I ended up redoing the project (and wasting time and money).

With HPVA plywood, you’re paying for consistency. That means:

- Professional appearance – smooth, high-grade veneers.

- Reliable structure – fewer voids in the core.

- Healthier indoor air – low-emission adhesives (CARB Phase 2 & TSCA Title VI compliant).

- Responsible sourcing – many panels also carry FSC certification for sustainable forestry.

If you’re building something for your home—or for a client—this consistency is what separates a “good enough” project from one that truly looks and feels professional.

Where HPVA Plywood Shines

I don’t waste HPVA plywood on quick jigs or workshop utility shelves. For me, it’s reserved for the projects where the wood is visible and needs to hold up long-term.

Here are the kinds of projects I reach for HPVA panels:

- Kitchen and bathroom cabinets – where every detail shows.

- Floating shelves and built-ins – especially in living rooms.

- Drawer boxes and closet systems – where smooth edges matter.

- Furniture – desks, vanities, wardrobes, and entertainment centers.

- Accent walls or interior paneling – where uniform grain makes a big impact.

Basically, if the piece is going to be front-and-center in a home, I want HPVA plywood backing me up.

Veneer Options That Fit Any Style

One of the best parts about HPVA plywood is the variety of veneer species available. That flexibility lets me match plywood to the design style of each project:

- Birch – smooth, light grain; easy to finish.

- Maple – clean and modern; stains consistently.

- Walnut – rich dark tones; instantly upscale.

- Cherry – reddish warmth that deepens with age.

- Oak – bold grain, traditional look.

- Mahogany – deep, elegant, and classic.

- Beech – subtle, strong, and easy to work.

- Alder – affordable and versatile; stains beautifully.

For example, I’ve used maple HPVA plywood in a set of shaker-style cabinets—it gave me a clean, bright look that painted perfectly. For a mid-century modern coffee table, I went with walnut veneer, and it turned out stunning.

Core Construction: What’s Inside Matters

The outer veneer catches the eye, but the core construction determines how the panel behaves. HPVA plywood comes in a few different core types, each with its own strengths.

| Core Type | Best Use Case | Why It Matters |

|---|---|---|

| Veneer Core | Cabinets, shelving | Lightweight, strong, stable |

| MDF Core | Painted projects, smooth panels | Flat, consistent, no grain telegraphing |

| Particleboard | Budget cabinetry | Cost-effective but less durable |

| Combination Core | Furniture panels | Blend of stability and smoothness |

When I built a painted storage bench, I chose MDF core because it gave me a flawless surface. For open shelving, veneer core was my pick—lighter, but still strong.

Choosing the Right HPVA Plywood for Your Project

Not every project calls for the same sheet of plywood. Even within HPVA-certified panels, there are choices you’ll want to make depending on your budget, finish, and the way the piece will be used. Picking carefully saves money and prevents frustration later.

Think About the Final Finish

If you’re planning to stain or clear coat, go with a veneer species that matches the look you’re after. Maple and birch give you a light, modern tone, while walnut or cherry offer richer colors that stand out in furniture builds. If the project will be painted, an MDF core with a simple veneer is often the smarter, more affordable choice.

Match the Core to the Application

Cores matter more than many beginners realize. A veneer core keeps cabinets light but strong, while a combination core balances durability with a flat surface that takes edge banding cleanly. For shop jigs or pieces that won’t show, particleboard-core plywood can save money without hurting performance.

Don’t Forget Availability

Some HPVA panels are easier to find than others. Common veneers like birch and maple are stocked widely, but if you’re hunting for exotic looks—like mahogany or alder—you may need to special order from a cabinet supplier instead of a big-box store. Planning keeps your project on schedule.

How to Spot Authentic HPVA Plywood

Not every panel marketed as “hardwood plywood” is the real deal. If you want certified quality, here’s what to check before you buy:

- Look for an APA or HPVA stamp on the edge or back.

- Confirm ANSI/HPVA HP-1 compliance.

- Ask about CARB Phase 2/TSCA Title VI certification for emissions.

- Don’t be shy—ask your supplier directly.

I’ve seen panels mislabeled at big box stores, so I always double-check. A quick conversation with the staff can save you from bringing home the wrong product.

Tools and Products That Work Well With HPVA Plywood

Because these panels are built for precision, the right tools make a big difference. Here are some of my favorites:

- Digital Caliper – quick thickness checks (panels aren’t always exact).

- DEWALT Orbital Sander–smooth veneer prep without over-sanding.

- General Finishes Gel Stain – even color, minimal blotching.

- Minwax Polycrylic – clear protective topcoat that won’t yellow.

- PureBond Birch Panels – FSC-certified, HPVA-compliant plywood available at Home Depot.

(Affiliate picks – these are products I’ve used myself or trust in my shop.)

Shop Tips for Flawless Results

Over time, I’ve picked up a few tricks for getting the most out of HPVA plywood:

- Use a fine-tooth blade for cuts; the thin veneer needs a clean edge.

- Lay down painter’s tape over cut lines to prevent splintering.

- Sand lightly with 220-grit paper before applying stain.

- Always match edge banding to your veneer species for a seamless look.

- Store panels flat and dry—even the best plywood can warp if neglected.

These little habits are what keep my projects looking sharp years later.

HPVA vs. Other Plywood Types

It helps to see where HPVA plywood fits compared to the other stuff you’ll run into at the yard.

Take CDX plywood, for example. It’s tough and affordable, which makes it perfect for subfloors, roof decking, or rough framing. But try building a cabinet with it and you’ll quickly regret it—the surfaces are too uneven, and finishing it nicely is almost impossible.

Then there’s marine-grade plywood. It’s the king of moisture resistance and great if you’re building a boat or something that’s going to sit outside year-round. For indoor projects, though, it’s like bringing a sledgehammer to hang a picture—unnecessary and expensive.

You’ll also find plenty of so-called hardwood plywood that isn’t certified. Some sheets are fine, but others are riddled with voids in the core or mismatched veneers. Buying it feels like a gamble, and I’ve lost that bet enough times to know better.

HPVA plywood lands right in the middle. It gives you the consistent quality you need for cabinets, furniture, and visible projects—strong enough to last, smooth enough to finish beautifully—without paying for features you don’t need indoors.

Pros and Cons

Every material has trade-offs. Here’s the quick take on HPVA plywood:

Pros

- Beautiful, uniform veneers

- Reliable bonding and durability

- Safer indoor air (low emissions)

- Easy to stain and finish

- Wide range of veneer species

Cons

- Higher cost than ungraded plywood

- Limited availability in smaller markets

- Not designed for exterior use

- Thin veneers—sand too aggressively and you’ll cut through

Where to Buy HPVA Plywood

If you’re ready to source certified panels, here are good starting points:

- Local cabinet suppliers – often the best selection.

- Home Depot / Lowe’s – check PureBond for FSC + HPVA options.

- Woodcraft or Rockler – reliable online suppliers.

I recommend buying locally, if possible, as it allows you to inspect each sheet before loading it into your truck.

Sustainability and Air Quality

Over the years, I’ve started paying closer attention to what the materials I use are made of—not just how they look. Anyone who’s cracked open a fresh sheet of cheap plywood knows that chemical smell that hangs in the air for hours. It’s not something I want in my shop, and definitely not in my home.

That’s why I appreciate that a lot of HPVA plywood today is made as NAUF (No Added Urea Formaldehyde). In plain terms, it means the panels don’t give off the harsh fumes that older or lower-grade products often do. Additionally, many certified sheets carry FSC labels, indicating that the wood itself comes from forests that are managed responsibly, rather than being stripped bare.

For me, it’s reassuring. I can build a set of cabinets for my kitchen—or for a client’s living room—and know I’m not filling the house with unwanted chemicals. It’s better for the air we breathe, and it feels better knowing the materials came from a sustainable source.

Final Thoughts

If there’s one thing I’ve learned, it’s this: cheap plywood costs more in the long run. Between warped shelves, blotchy finishes, and failed cores, those savings vanish quickly.

When the project matters—whether it’s a kitchen, a built-in, or a piece of furniture that you’ll pass down—HPVA plywood is worth every penny. It gives you the confidence that your work will hold up, look good, and stay safe indoors.

So next time you’re standing in the lumber aisle debating between generic panels and certified sheets, remember: your craftsmanship deserves the best foundation. Choose HPVA plywood—and build something that lasts.