If you’ve ever spent time in a garage workshop or browsed lumber at a home center, you’ve probably come across birch plywood. It doesn’t just look good—it performs exceptionally well in furniture, cabinets, and even shop jigs.

Over the years, I’ve come to rely on birch plywood more than almost any other sheet material. It perfectly balances strength, ease of use, and a clean finish. Let’s break down what makes this plywood so versatile and why it continues to be a favorite among builders, hobbyists, and pros alike.

What Exactly Is Birch Plywood?

At its core, birch plywood is made up of several thin layers of birch veneer, all glued together with alternating grain directions. This layering technique—called cross-lamination—is what gives it both strength and resistance to warping.

There are two main types:

- Baltic Birch, which is imported from countries like Finland and Russia, is known for its high-quality, void-free core.

- Domestic Birch, sourced from North America, tends to be more budget-friendly but may include a softer or mixed core.

If you’re building furniture or working on projects that require clean, visible edges, Baltic Birch is often worth the extra cost.

What Makes Birch Plywood Stand Out?

Here’s what I’ve noticed after using it on dozens of projects:

- Tough and stable – It holds up under pressure, whether you’re building floating shelves or heavy-duty shop cabinets.

- Takes finish well – The tight grain accepts paint and stain beautifully when prepped right.

- Easy to cut and drill – It doesn’t splinter much and holds screws tightly.

- Eco-friendly options – Many suppliers offer birch plywood with FSC certification, ensuring it comes from responsibly managed forests.

Unlike cheaper plywoods that can feel like working with cardboard, birch gives you confidence when cutting, screwing, or even laser-engraving.

Birch Plywood Grades (And Why They Matter)

If you’ve ever been confused by plywood grades, you’re not alone. Here’s a simple breakdown of the most common birch grades:

| Grade | Description |

|---|---|

| B/BB | One face is clear, the back might have small patches—great for cabinet doors and drawer fronts |

| BB/BB | Both sides have visible plugs but are still smooth—good for less visible furniture parts |

| CP/CP | More patches, discoloration—best for painting or utility use |

| C/C | Rougher surfaces, not great for aesthetics—used behind drywall or for structural use |

Baltic Birch vs. Domestic Birch: What’s the Real Difference?

| Feature | Baltic Birch | Domestic Birch |

|---|---|---|

| Core Quality | Solid veneer, no voids | Often has filler strips or knots |

| Appearance | Clean, uniform | May have visible face repairs |

| Sheet Size | 5’x5′ metric size | 4’x8′ standard U.S. size |

| Price | Premium | More affordable |

I prefer Baltic Birch for visible projects—like cabinetry or desks—where I want that extra polish. But for garage builds, shop jigs, or quick utility furniture, domestic birch gets the job done at a better price point.

Common Birch Plywood Sizes and Thicknesses

You’ll find birch sheets in the following standard dimensions:

- Thicknesses: 1/8″, 1/4″, 1/2″, 3/4″, and sometimes up to 1″

- Sheet sizes:

- Baltic: 5’x5′

- Domestic: 4’x8′

Keep in mind that thickness may vary slightly from what’s labeled, especially with imported plywood. Always measure before final cuts, especially when fitting panels into pre-cut dadoes or grooves.

Real-World Projects You Can Build with Birch Plywood

Here are just a few ways I’ve used birch plywood over the years:

- Kitchen Cabinets – Its strength and smooth finish make it perfect for drawer boxes and cabinet carcasses.

🔗 Read: Best plywood types for cabinets - Garage Shelving – Holds serious weight without sagging.

- Workbenches and Jigs – I’ve built router tables, sleds, and even a miter station with it.

- Floating Desks – The clean edges and lightweight design make it great for wall-mounted furniture.

- Laser Engraving Projects – Ideal for signs, coasters, or intricate cuts.

Buying Tips: What to Look for When Purchasing Birch Plywood

Not all plywood is created equal. Here’s what I always check before buying:

- Flatness – Warped sheets are a nightmare to work with.

- Core visibility – Look at the edges to spot voids or filler strips.

- Face grain – The cleaner the face, the less work you’ll have to do during finishing.

- Moisture resistance – For outdoor or damp-area projects, go for marine-grade or exterior-rated plywood.

You can usually find birch plywood at The Home Depot, Lowe’s, or specialty stores like Rockler. For online orders, I’ve had good luck with:

Finishing Birch Plywood Without Blotches

Here’s the thing about birch—it doesn’t always take stain evenly. But that doesn’t mean you can’t get a beautiful finish.

My Go-To Process:

- Sand with 180 to 220 grit

- Apply a pre-stain wood conditioner (don’t skip this!)

- Use a gel stain for even color

- Seal with polyurethane or lacquer

Favorite Products:

- General Finishes Pre-Stain Conditioner

- Varathane Gel Stain – Antique Walnut

- Purdy 2” Brush for Detail Work

Birch vs. Other Sheet Goods

| Compared To | Why Birch Wins |

|---|---|

| MDF | Birch is stronger and holds screws better |

| Pine Plywood | Birch is smoother and more stable |

| Oak Plywood | Birch is lighter and easier to work with |

If I had to pick just one plywood for general-purpose DIY, birch would be it.

How to Make Birch Plywood Edges Look Great

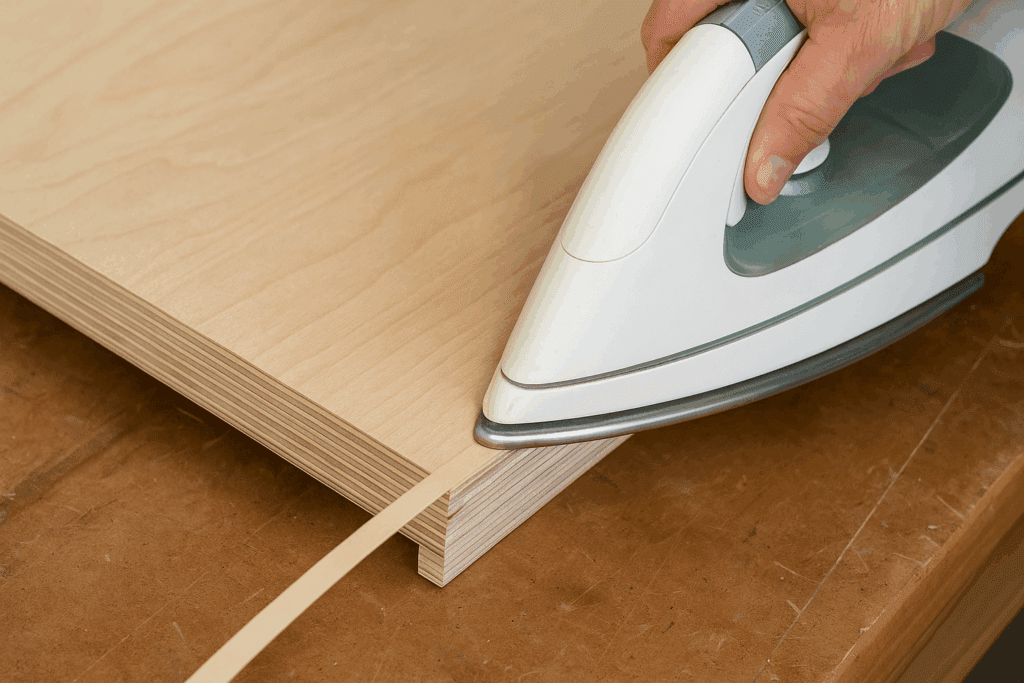

Unfinished edges can be a giveaway that something was DIY’d. A quick fix? Edge banding.

- Use iron-on birch veneer tape

- Trim with a razor or utility knife

- Sand lightly and finish to match the face

Step-by-step edge finishing tutorial

Troubleshooting Common Issues with Birch Plywood

Even though birch plywood is considered a premium choice, no material is completely foolproof. If you’re working with it for the first time, you might run into a few hiccups. Here are some real-world issues I’ve come across—and how to fix them.

1. Splintering While Cutting

If your cuts aren’t clean, you’re probably using the wrong blade. Birch plywood is dense, so a high-tooth-count blade (like 80T or higher) is your best friend. A sacrificial backer board can also help prevent tear-out, especially with crosscuts.

Pro tip: For circular saws, score the cut line with a utility knife to reduce surface splintering.

2. Blotchy or Uneven Stain

This happens a lot. Birch’s grain is tight but inconsistent, which means it soaks up stain unpredictably. Always test your stain on a scrap piece first. A good wood conditioner or shellac-based sealer before staining can work wonders.

Don’t forget to sand again lightly after applying the conditioner to open up the grain just a bit.

3. Delamination or Edge Separation

While rare in high-quality Baltic Birch, domestic versions sometimes peel along the edges, especially if exposed to moisture. Avoid storing sheets flat on cold concrete. Instead, elevate them slightly and keep them in a dry place.

4. Screw Blowout

If your screw splits the edge, you’re likely too close to the edge or not pre-drilling. Birch holds screws well, but still needs pilot holes to prevent cracking.

Frequently Asked Questions

Can I use birch plywood outside?

Only if you seal it properly. Use an exterior-rated or marine-grade version and finish all sides.

Is birch plywood waterproof?

Not by itself, but it becomes water-resistant with a good sealer or polyurethane.

Why does birch stain blotchy?

The tight grain absorbs stain unevenly—always use a conditioner before applying color.

Final Thoughts: Why Birch Plywood Belongs in Your Next Build

Working with birch plywood has taught me to appreciate materials that balance performance with workability. Yes, it takes a little more prep and planning than basic plywood, but the payoff is always worth it. Whether you’re installing a floating desk, building built-ins, or just crafting shop jigs that make your workflow smoother, birch has you covered.