What is Plytanium Plywood?

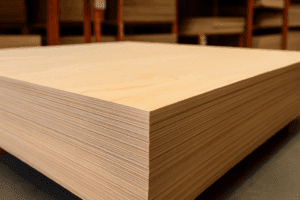

Plytanium Plywood is a brand of plywood manufactured by Georgia-Pacific, a company known for producing building materials. Plytanium Plywood is designed for use in various construction and woodworking projects. It typically features a combination of durability and versatility, making it suitable for flooring, wall sheathing, and roofing applications.

The plywood is often made with a high-quality veneer face and a sturdy core, offering good structural integrity. It’s available in different grades and thicknesses, allowing it to meet specific project requirements. Plytanium Plywood may also be treated to resist moisture and insects, enhancing its performance in challenging environments.

Benefits of Plytamium Plywood

Plytanium plywood offers numerous benefits, including an attractive appearance when painted or stained. Additionally, its sustainable forestry initiative ensures that the wood is sourced responsibly. Furthermore, the plywood is certified by a third party for quality and environmental sustainability. This commitment to excellence also extends to its performance, with reduced edge swell providing improved stability and less waste. These features make Plytanium plywood a reliable and eco-friendly choice for various applications.

Plytanium plywood is known for its durability and performance. Here are some of the key benefits and advantages of using Plytanium plywood:

- Durability: Plytanium plywood is designed to be highly durable, making it suitable for both structural and aesthetic applications. It can withstand various environmental conditions, including moisture and temperature fluctuations.

- Strength: The plywood is engineered for high strength, providing excellent support and stability for construction projects. This strength helps in maintaining the integrity of structures over time.

- Moisture Resistance: Plytanium plywood often features moisture-resistant properties, which make it a good choice for areas exposed to higher humidity or potential water contact. This resistance helps prevent issues like warping, swelling, or delamination.

- Versatility: It can be used in various applications, from flooring and roofing to wall sheathing and cabinetry. Its versatility makes it a popular choice for both residential and commercial projects.

- Ease of Use: Plytanium plywood is relatively easy to work with. It can be cut, shaped, and installed with standard woodworking tools to streamline construction processes.

- Cost-Effective: Compared to other types of plywood or building materials, Plytanium plywood offers a balance of quality and cost, making it a cost-effective option for many projects.

- Consistent Quality: LP maintains high manufacturing standards, resulting in consistent product quality. This reliability can reduce issues related to material performance and project delays.

- Environmental Considerations: Some Plytanium products are designed sustainably, using materials and processes to reduce environmental impact.

- Aesthetic Options: Depending on the specific product line, Plytanium plywood can be finished in various ways or be ready for painting or staining, offering flexibility for design and aesthetic preferences.

- Support and Warranty: LP typically offers warranties and support for their products, providing peace of mind regarding the performance and longevity of Plytanium plywood.

Plytanium plywood is favored for its strength, durability, and versatility, making it a solid choice for many construction and renovation projects.

Use for Plytanium Plywood

Plytanium Plywood is a versatile material used in various construction and woodworking applications. Some common uses include:

Interior Applications

- Furniture-making and woodworking projects

- Shelving and cabinetry

- Sub-flooring and underlayment for hardwood flooring, carpet, and pad

- Wall paneling and decorative accents

Exterior Applications

- Roof sheathing and wall sheathing applications

- Porch ceilings and soffits

- Exterior furniture and decking

- Light commercial construction projects

Ideal Project Panel

- Plytanium Sanded Panels are ideal for projects requiring a smooth, sanded face

- Suitable for interior and exterior applications, including furniture making and exterior construction

- Available in various thicknesses, including 1/4 CAT, 11/32 CAT, and 15/32 CAT

Types of Plytanium Plywood

- Plytanium Sturd-I-Floor Plywood for sub-flooring and underlayment

- DryPly Plywood for dry interior applications

- DryMax High-Performance OSB for high-traffic areas and exterior applications

- Plytanium Sheathing for roof and wall sheathing applications

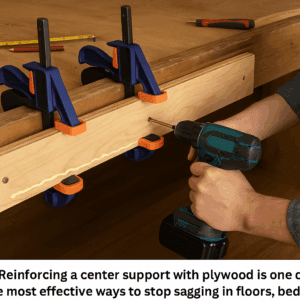

Working with Plytanium Plywood

- Easy to work with and install

- Can be stained, finished, or painted to suit personal taste

- Common thicknesses include 1/4-inch, 1/2-inch, and 3/4-inch

Choosing the Right Plytanium Plywood

- Consider the specific application and required thickness

- Look for third-party certification and sustainable forestry initiative

- Choose from various types and sizes to suit your project needs

- Contact Georgia-Pacific for more information and to find a distributor near you.

More About Plytanium Plywood

Plytanium is a trade name registered with Georgia Pacific, the nation’s largest manufacturer of plywood products. It is their premium softwood plywood product, and although not rated as such, it should probably be considered an ACX-rated plywood. The Plytanium line of plywood products contains several products designed for different applications.

Plytanium panels are advertised as “stiff and strong,” flatter than some other plywood products, and clearly better able to handle impact without breaking than OSB and some other plywood products that it competes with. They also provide considerably less edge swell than OSB, which is notorious for this problem.

Since the general term “plywood” now means all plywood products, specifying Plytanium on a construction project ensures that a softwood plywood product, made of alternate wood veneers bonded by rosin, is used. Otherwise, simply specifying plywood could leave the contractor wiggle room to use OSB to save money, as it meets building code and is a plywood product. While there is nothing wrong with OSB as a building material, it is not as strong as softwood plywood, regardless of what the building code says.

Georgia Pacific makes several claims about this plywood, including that it is “green-certified” and has low formaldehyde emissions. This tells us that they have taken care to produce a quality softwood plywood product, which uses bonding resins that are less harmful than those used in some other plywood products. While not the only formaldehyde-free plywood product around, considering that formaldehyde is considered a carcinogen, using a formaldehyde-free plywood product in your home can provide a health benefit to your family.

Although Plytanium is not a “treated” plywood, it is an exterior-grade plywood. That means that it can be used for home sheathing without concern that it will delaminate due to rain during construction. This rating doesn’t mean that the plywood can be left exposed to the elements without problem; merely that it can during the relatively short time that construction is going on.

Many Plytanium products are also sanded sheets, which is uncommon for most softwood plywood products, as they are used primarily for construction. However, many construction applications require a smooth surface, such as subflooring. By providing its customers with an already sanded surface, Plytanium reduces the labor necessary for subflooring prep or using its product for various other non-construction projects.

Specifying Plytanium for any project ensures a quality softwood plywood product, which will provide strength and an attractive appearance in the finished project. The quality level will be consistent, even if additional material is ordered to be added to the project at some later date. It is available throughout the United States.

Plytanium Subflooring

Georgia Pacific’s Plytanium subflooring is referred to as “Sturd-I-Floor,” and it is intended to send a message to the buyer. It is designed to provide stiffness and stability and is available in 19/32”, 23/32” and 1-1/8” thick sheets. While 19/32” doesn’t meet the code for subflooring, without a second layer, 23/32” and 1-1/8” thick does. For applications where ceramic tile is to be installed, the 1-1/8” thick sheets provide the stability necessary without a second layer of subflooring.

These 4’ x 8’ sheets are cut tongue and groove for positive location and connection, leaving no gaps between sheets. The face surface is sanded, ensuring a smooth surface for any flooring applied. While this is important for any sort of flooring, it is especially important for ceramic tile floors or vinyl flooring.

Plytanium Sheathing

Roof and wall sheathing in the Plytanium line are not sanded, as it is unnecessary. Unlike flooring or paint, the sheathing is always covered with other materials, which do not require a smooth surface. However, as an exterior-grade product, Plytanium sheathing provides weather protection with a lower risk of edge swelling than OSB and other products.

Plytanium sheathing is available in 3/8”, 15/32”, 19/32”, and 23/32” thicknesses in 4’ x 8’ sheets. The 15/32” and 19/32” are most commonly used for exterior wall and roof sheathing, while 3/8” is only used in non-structural applications.

Plytanium Siding

There is also T-111 siding in the Plytanium line. Finished with a rough-sawn texture, this is an excellent siding choice for low-cost construction with a desired rustic appearance. Being made of softwood plywood, it is considerably stronger than T-111 panels made of concrete in other ways and is much less prone to delamination and edge swelling.

Plytanium Siding has a shiplap edge, allowing for a seamless installation with no gaps that water can seep through. Nevertheless, it should be installed over a house wrap to meet the building code. Panels are available in 11/32”, 15/32” and 19/32” thicknesses.

Plytanium Sanded Panels

Plytanium also comes in sanded panels for furniture, various cabinets, and other projects where plywood is an appropriate material. Pre-sanding provides an attractive, high-quality surface that can be painted, stained, or torched, depending on the application. Unlike other softwood plywood, Plytanium sanded panels provide these projects with a smooth, defect-free surface.

These sanded panels can also be used in home construction applications where the plywood is left exposed for cabinets, such as soffits, built-in shelving, and painted cabinets. It is available in 1/4”, 11/32”, 15/32”, 19/32” and 23/32” thicknesses.

Plytanium by Georgia Pacific, Mike Mozart

Cutting Plytanium

As with any other plywood product, care should be taken when cutting Plytanium, especially across the face grain. While this is not much of an issue in some applications, such as siding, splintering can be a major issue with some projects, especially on walls where the plywood will be the visible surface.

Always use a sharp blade when crosscutting, preferably with a high tooth count. Carbide-tipped blades will remain sharp longer, helping to provide a clean cut with minimal tear-out. Because the carbide tips are wider than the blade’s body, there is less friction to cause tear-out or burning when cutting.