Definition

Although you hear the term “furniture grade plywood” bandied around occasionally (usually by people who don’t know any better), there is no such thing. Furniture is an application in which plywood is used, but there is no such grade. Instead, the term “furniture grade” is loosely used, primarily referring to plywood with a letter grade identifying the quality of face veneer, which would make it acceptable for use in building furniture.

What is Cabinet Grade Plywood

This finish grade is usually only found on hardwood plywood, sometimes called “cabinet grade plywood,” because it is commonly used for cabinetry. But it can also be found on softwood plywood if you look hard enough. It’s impossible to find such a high-quality finish on products like OSB (oriented strand board) and MDF (medium-density fiberboard) because of how they are made and the material they are made from.

Most hardwoods used to manufacture furniture and cabinetry, such as cabinets, tables, chairs, etc., come graded as “A1,” referring to the face side being A-grade and the back side being grade 1. The grading system looks like this:

Visible Face Grades:

- AA – Good or good sequence

- A – Good

- B – Good, sliced B, RC sound

- C – Rotary cut solid

Back Face Grades:

- Sound, same species, specifically cut

- Solid, same species, specifically cut

- Rotary Grain

- Reject Back

Cabinet Grade Plywood = Birch Plywood

The idea of calling some plywood “furniture grade plywood” comes from using high-grade hardwood plywood for making furniture, even though it is an inaccurate term. On the other hand, Cabinet grade plywood is a term used most commonly for birch plywood, a popular hardwood plywood for building furniture for kitchen and bathroom cabinets.

Why is Birch Plywood Popular?

Birch plywood, also known as cabinet-grade plywood, is famous for cabinets for two reasons. First, it generally has a thicker face veneer than other hardwood plywood. This is advantageous when finishing; you don’t have to be overly careful sanding to avoid sanding through the face veneer. Even if you did sand through the face veneer (not that you want to), you’d find that the core veneers of birch plywood are also made of birch, unlike other hardwood plywood, which uses a softwood veneer core.

Cabinet Grade Plywood is Expensive – USE MDF

However, hardwood isn’t the only thing used for building cabinets. Cabinet-grade plywood can be rather expensive. MDF (medium-density fiberboard) is a popular alternative for building furniture cabinets to be painted rather than stained and varnished. Since the wood grain is immaterial in painted cabinets, MDF provides a smoother surface finish for cabinet work at a lower overall cost.

Types of Furniture Plywood

Again, hardwood or softwood plywood can be used in furniture construction. Some of the more commonly used furniture-grade plywood types are:

- Oak – is very popular in the US for both furniture and cabinetry. The open grain creates an excellent contrast, providing beautiful furniture with a somewhat rustic style.

- Mahogany – this type of plywood is one of the most commonly used cabinets worldwide.

- Cherry – the red tone of cherry wood provides a sense of richness not found in other hardwood types. It is most often used for high-end furniture.

- Maple – another American favorite, usually stained dark.

- Baltic Birch – is commonly used for both cabinetry and shop-type furniture. When used for cabinetry, it is often stained to give the appearance of other hardwoods. However, this is the type of plywood usually avoided for shop furniture.

- Tiger Maple – a common choice for custom-made furniture.

Recommendations

Any of the three types of plywood listed above. As well as many others, can be used in any furniture construction project. However, due to differences in costs and appearance, not all are recommended for every project.

For instance, Mahogany is the most often used plywood in cabinet construction projects. At the same time, it can be used to make furniture pieces (many people also own Mahogany dining tables). It is not recommended for a shop, shed, garage, etc., project. Because Mahogany is one of the more expensive types of plywood, it should be used where aesthetic quality is essential.

On the other hand, Baltic Birch is great for use in these locations since it is simple, easy to work with, durable, and cost-efficient.

Tiger Maple is durable and has an interesting pattern, which makes it great for custom furniture. It is important to note that both durability and look are essential when it comes to building furniture.

Uses

The hardwood that is often thought of as furniture-grade plywood is often used for what the name implies, making furniture; hence the confusion on its name. But it is also used for making cabinetry. Depending on whether you consider cabinetry to be furniture or not, calling it furniture grade could work for cabinets as well.

While not everything in a piece of furniture can be made of plywood, it is ideal for large, flat parts, such as tabletops, the sides of carcasses (dresser cases), shelving, backs, cabinet doors, and facing. These plywood pieces are often edged with hardwood pieces of the same wood type, creating the appearance that the whole project has been done out of hardwood when only the edge pieces and surface veneers are of that hardwood.

Softwood plywood is also used for more practical furniture, such as workbenches, storage shelves, folding tables for laundry rooms, and work tables for craft rooms. The significant difference between these applications and those where hardwood plywood might be used is that there is no reason to have fine furniture used in those applications.

Going even further down on the cost scale, MDF and particleboard manufacture much of the commercial furniture built today, even quality. A wood grain vinyl covering is often applied directly to the plywood. However, in the case of projects made with MDF, the surface finish of the plywood might be the color coat, made to have the appearance of very smooth paint. This is especially common with the type of furniture that you have to assemble yourself.

Using furniture grade plywood in your furniture projects

The key to using hardwood or furniture-grade plywood in your projects is to hide the edges of the cut pieces, covering them with matching hardwood. Doing this usually requires careful machining and finishing sanding to match the details up to make them look like they belong, rather than you trying to hide something.

It is best to cut the hardwood edge and corner pieces slightly proud, allowing you to plane or sand them flush with the plywood. You can’t take off from the plywood if it is proud, as the face veneer is too thin to allow that without damage. But the solid hardwood edge shouldn’t have any problems being trimmed and sanded.

Care must be taken when cutting hardwood plywood not to chip out the face veneer. Always cut from the back side of the sheet to help prevent this. Taping the cut line on both sides with masking tape will also help prevent chipping and splintering.

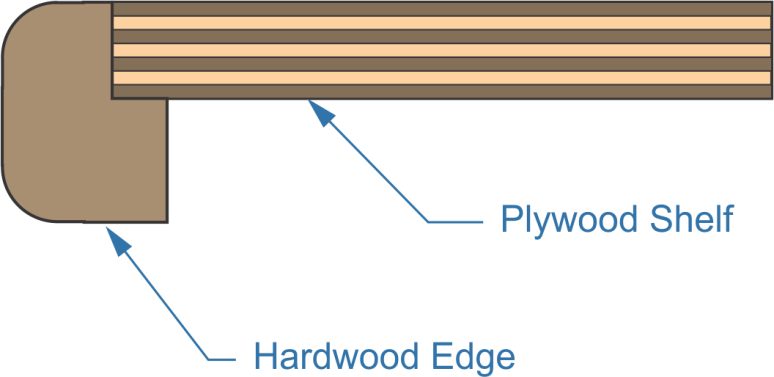

In the diagram above, a hardwood edge has been added to a piece of hardwood plywood being used as a shelf. The extra thickness of the hardwood piece augments the thickness of the plywood, making a ½” thick piece of plywood have roughly the same stiffness as a 1″ piece of plywood would. This provides good aesthetics while strengthening the shelf at the same time.

In this case, the edges of the hardwood piece have been rounded at a ¼” radius; other patterns, such as a chamfer, beading, cove, or Roman ogee, could just as well be applied, using a router and the appropriate bit.

Instead of using a piece of hardwood, either routed or plain, hardwood edging can be glued to the edge of the shelf. It is installed using a clothes iron to heat the glue, adhering the two pieces together. You can buy hardwood veneer shelf edging of this type, which comes with hot melt glue already applied to one side.

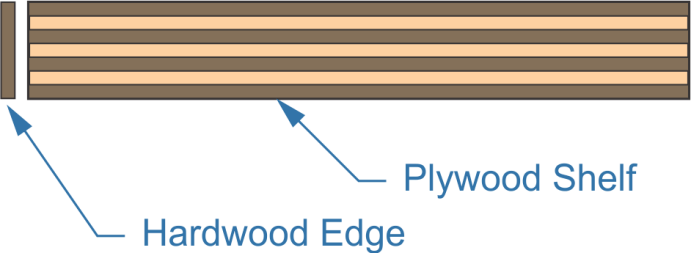

If you cannot find an appropriate veneer edging on your shelves, you can do the same by cutting a thin strip of hardwood (1/8″ thick) and gluing it on the edge of the plywood board. Plane and sand it to remove saw blade marks and finish it to match the rest of the project.

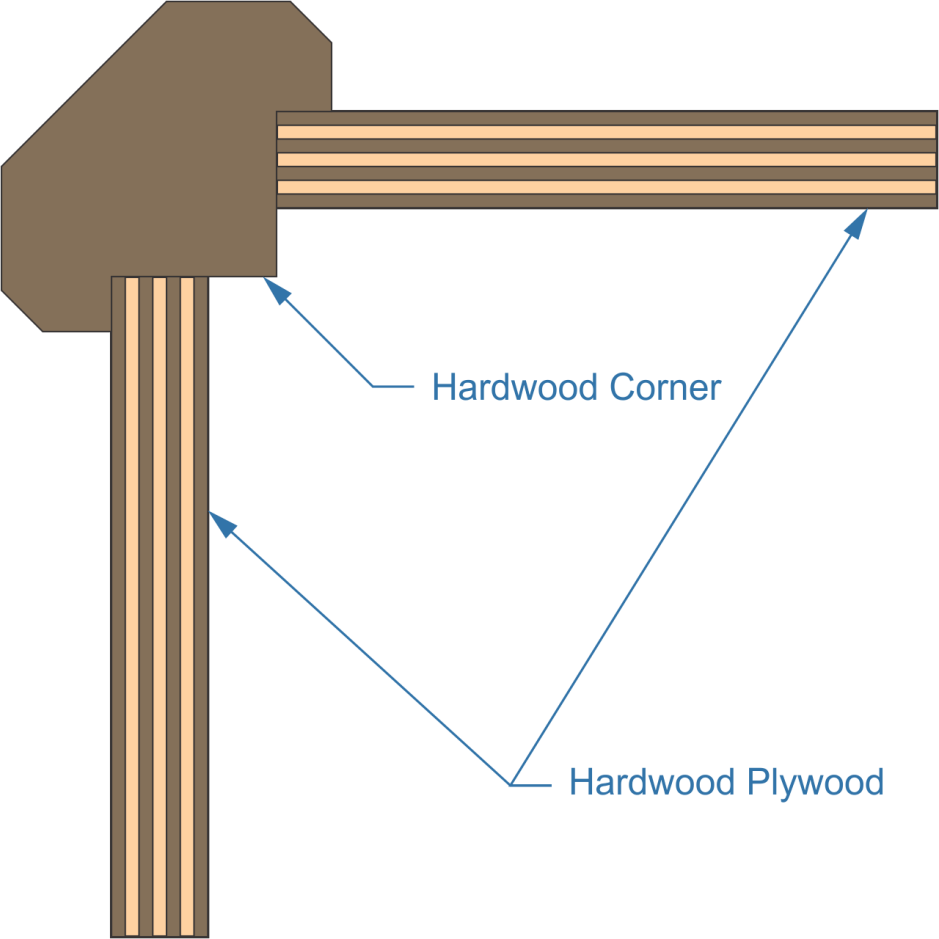

This diagram has two pieces of hardwood ply, making two sides of a box. This could be a carcase for a dresser or the supporting lip under the edge of a table. Regardless of what it is, the hardwood corner is finishing the edges of both pieces of plywood. The corner piece in this diagram could be cut on a table saw or a router. While I considered using it as a corner on a carcase, I realized the same construction could be used for a table leg when drawing it.

You can machine your corner pieces, give them the desired profile, or work with standard architectural trim. Creative use of architectural trim can make for some rather fancy corners on cabinetry.

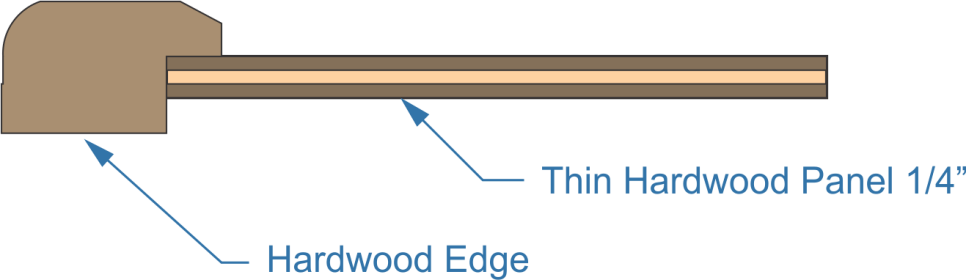

Cabinet doors can be made similarly, cutting out a step on the inside of the frame for the ¼” hardwood ply flat panel and milling the face of the frame as you desire. The edge, or frame, above has a chamfer on the inner edge and is radiused on the outer edge. However, it would be much more likely to pick one or the other and not use both together.

Creating an “industrial” look

A look that has become popular in more recent times is the industrial look. This mimics the industrial furniture used in manufacturing and packaging for shipping operations. Specific hardwood plywood is used for this due to its durability. An unexpected result is that this look is attractive enough that it has moved from the factory floor to the classroom and some casual stores. We now find it being used in homes, as well.

Baltic Birch plywood and Applewood are two of the most popular plywood products. The identifying design feature is the exposed edges of plywood tabletops, side pieces, and dividers. These edges are attractive because of the types of plywood used, which have a lot of consistent core veneer layers and are made essentially without voids.

Baltic Birch is a beautiful plywood to work with because the core is also made out of birch. Because everything is made of the same wood, the face, and back veneers are thicker, making them much easier to finish. This provides for a very stable plywood product.

Plywood panels are usually used with a welded metal framework for this style. The attaching hardware is often finished to match the framework and could be installed countersunk or left proud with a face washer. The edges of the plywood panels are routed with an oval bit, giving them a curve, which helps prevent splintering without having to go to a full bullnose. The primary difference is that a bullnose is a half circle, while the oval edge is a half oval.

PVC and plywood

Since PVC pipe was invented, people have been searching for new ways to use it. Many projects have been completed, including greenhouses, bike racks, soccer goalposts, and furniture. Another style that is becoming more popular for classrooms, children’s beds and playrooms, and patio furniture is to combine furniture-grade plywood with furniture-grade PVC. The ease of working with PVC and the wide variety of connectors available makes it a prime building material for quick and easy projects.

Furniture-grade PVC pipe is typically Schedule 40, just like the pipe used for plumbing, but it is available in various colors. The couplings, however, are not rated and are usually a little thinner walled than those used for plumbing. That’s okay, as they are not put under the same stresses. The fittings do not have all the mold marks and markings you would find on fittings intended for plumbing use.

Combining cabinet-grade plywood with PVC provides much more strength than PVC can provide alone. Attaching the plywood to the PVC pipe is done with hardware, just as with the industrial-style furniture mentioned above. The weight of whatever is going to be on that piece of furniture can be held by the plywood, spreading that weight out so that it doesn’t break the PVC framework.

Cabinet Making

When making cabinets, hardwood plywood is used slightly differently than when making furniture. Rather than trying to hide all the edges, the cabinet face pieces are often cut out of ¾” hardwood ply and then assembled as if the plywood was solid hardwood. Although the edges are left exposed, they will be visible only inside the door opening, someplace where people don’t bother looking.

Generally speaking, when the front outside edges of the cabinets are visible, such as the upper cabinets next to the sink, they will have a trim piece attached at the corner, covering up the edge of the plywood in all other cases. The edge of the plywood won’t be visible once installed because the cabinets will be butted up against one another or appliances.

Using hardwood, in this case, helps control the cost of the project, as plywood is considerably less expensive than hardwood would be. It also provides a surface that matches the ends of the cabinets and doors, helping keep the entire project consistent.

Fastening Furniture Grade Plywood

Furniture-grade plywood is expensive and easily damaged. Therefore, you want to take care of how you cut and fasten it. Cutting should always be done with sharp saw blades to help prevent chipping and splintering. Cut from the back side whenever possible.

As a general rule of thumb, projects made with furniture-grade plywood are glued together rather than screwed or nailed. That’s not to say that neither screws nor nails are used. Nails, especially pneumatically driven brads, are often used to hold projects together while drying, and screws are used to attach hardware or plywood panels to metal or PVC framework.

When gluing plywood panels together or to hardwood pieces, you mustn’t be only gluing end grain. End grain joints are not very strong, as the dried glue can pull out of them over time. The glue should be applied to the side grain, which will have a good “bite” into the wood’s pores and will not pull out. Fortunately, the edge of plywood sheets allows for this, as it has both end and side grain.

Always use clamps when gluing to hold the parts together. The tighter they are held together, the better the glue seam. Ideally, a minimal thickness of glue is all you want. Excessive thickness does not make the joint stronger. All glue-ups should be clamped to push the parts together and thin out the layer of glue.

Nails, specifically air-driven brads, can clamp plywood projects together and be left in place as part of the joinery. It is best if these nails are driven in from the back side of the plywood sheets, leaving them hidden, rather than having them exposed on the face of the workpiece. No matter how carefully you fill the nail holes, they will almost always remain visible to those who look for them. Better not to give them anything to look for.

Screws are often used to hold plywood panels together, but not on furniture. Rather, screws are commonly used for more simple projects, which will be used in the workshop, laundry room, or another work area in the home. While screws are a better fastener in plywood sheets than nails are, they are also much more visible.

Locations

Any plywood sheet can be purchased directly from the producer or manufacturer. However, manufacturers are usually only interested in selling full bunks of plywood. If you don’t need that much if someone does not want to go this route because of cost, timing, location, or whatever, many different types of plywood are always available at any local hardware store, lumberyard, or home improvement center. Some will even do special orders for you, allowing you to buy products they don’t normally have on the shelf.