Calipers are perhaps the most common instrument in existence for accurate measurement. By “accurate” I’m referring to something more accurate than you can accomplish with a ruler. While we may not think about it, woodworking regularly requires this degree of accuracy. Fitting a mortise and tenon, making a segmented shape like an octagon or a circle, doing dovetail or finger joints, even a simple miter joint all require extreme levels of accuracy.

This type of accuracy is normally thought of as what machinists accomplish with their tools. Yet those tools are actually considerably more accurate than the ones we have in our workshops. Adding a caliper, something the machinist uses regularly, to our tool kit helps us make up for that difference.

When we talk about calipers, there are actually several different tools that we can refer to:

- Inside and Outside Calipers – which don’t have a scale, but allow us to measure comparatively

- Vernier Calipers – where there is a vernier scale, allowing us to read in increments of .001 in. (one thousandth) or .01mm (one hundredth)

- Dial Calipers – which replace the vernier scale with a dial, making that reading easier

- Digital Calipers – a technological improvement, allowing us to read dimensions quicker, often down to an accuracy of .0001 in. (one ten-thousandths) or .001mm (one thousandth)

To help put those measurements in scale, an average human hair is 0.0027” thick. That’s almost three thousandths of an inch.

Outside calipers are often used by wood turners, especially when trying to match the size of their turnings, either because of producing several parts the same or because of making parts fit together. The lack of a scale is immaterial, as the calipers themselves provide the comparative measurement by how far the jaws are spread apart.

If it is necessary to make a measurement with a set of outside calipers, they are normally set to the size of the object being measured, then compared to a ruler or scale. That’s not as accurate as the measurements that can be made with other types of calipers, which have internal scales. However, it is possible to buy digital outside calipers, which will provide you with an actual reading of the measurement.

Measuring with Calipers

The other three types of calipers (vernier, dial and digital) all provide three different types of measurements. They are able to provide three basic types of measurements:

- External measurements

- Internal measurements

- Depth measurements

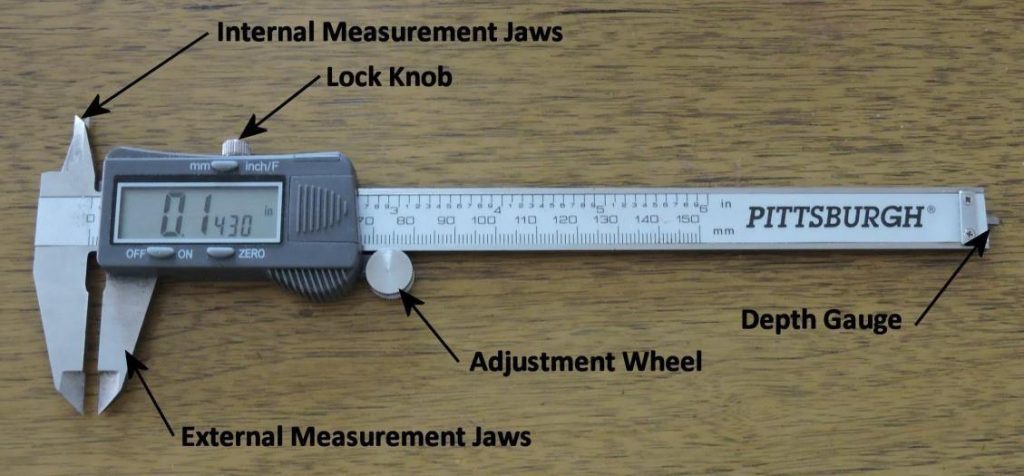

The external and internal measurements are accomplished using the jaws of the calipers, while the depth measurement is accomplished with the depth gauge, which comes out from the scale. You can see the various parts of the calipers that make the measurements in the photo of some digital calipers below. This particular set of calipers, like many available today, can measure both in inches and metric.

One side of the internal jaws, external jaws and the depth gauge on the calipers all move together, as the caliper is opened and closed. You can move them by the simple expedient of pulling the readout to the right, but the adjustment where is there, so that when you tighten the caliper down on the part to be measured, the amount of pressure will be consistent, helping to make measurements consistent.

In order to measure the outside of a part, the external measurement jaws are used. There is a flat-ground section of these, as well as a beveled, allowing you to select the portion of the jaws which will best mate with the part you are measuring.

The inside jaws, which are smaller than the outside jaws, are typically located on the top side of the caliper. They only provide a beveled edge, as that is necessary for accurately measuring the inside of a round hole.

To measure depth of a hole, the depth gauge is extended out the far right end of the scale. It is inserted into the hole, and then the caliper is closed until the end of the caliper scale makes contact with the surface of the part the hole is in.

The external and internal jaws of the caliper can be used together, for the purpose of verifying that parts fit together. One such application might be checking a mortar & tenon, measuring one and then locking the caliper in place, using the lock knob. Then the opposite set of jaws can be placed in or on the other part, verifying that it is the right size.

Reading the Calipers

Of all the types of calipers available, digital calipers are the easiest to read. Due to the prices of electronics constantly lowering, digital calipers of this type are extremely inexpensive today, cheaper than vernier or dial calipers. Yet they maintain the same level of accuracy.

You might also encounter mechanical digital calipers, rather than the electronic sort. These are not manufactured today, but you can find used ones available at times. The mechanical digital micrometer shown below uses the same sort of readout. The digital portion of the micrometer reads to .001” (one thousandth). There is also a vernier around the barrel of the handle, giving an overall accuracy of .0001” (one ten-thousandth).

Micrometers are used by machinists when greater accuracy is needed than that which a caliper can provide. However, they are not all that practical for woodworking, as micrometers only have a one inch range. The one shown above measures from 0” to 1”, to measure 1” to 2”, a different micrometer would be used. That means you need a set of six, to be able to measure what a six inch caliper can measure.

The one place where micrometers are extremely useful however, is for measuring shim stock.

Reading Dial Calipers

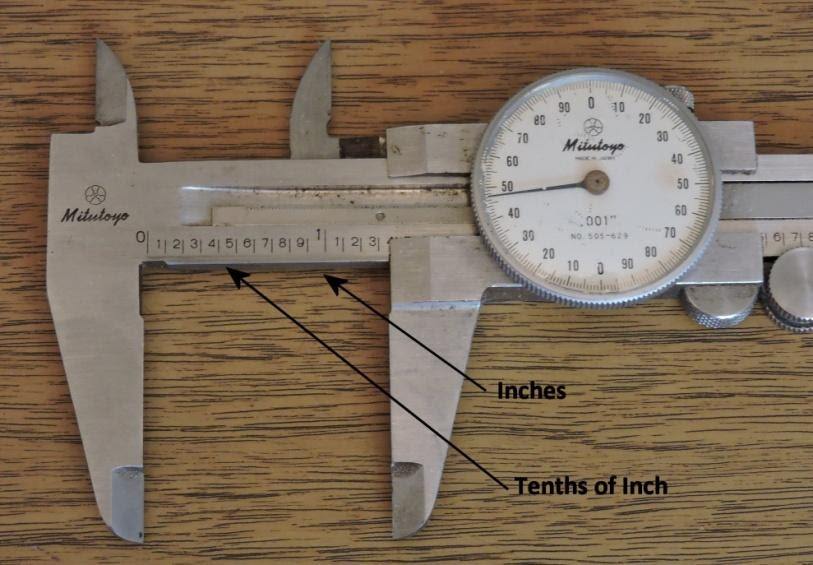

Dial calipers require considerably more skill to read than digital calipers. However, they really aren’t all that complicated. Inches and tenths of an inch or centimeters and millimeters are read off the dial. The set of calipers below are old, so they are only inch; but both are read the same way.

In the close-up image below, we can see that the external measurement jaws are open to the point where we can see the one inch marker. It is clear that it is inches and not tenths of an inch, in that it is raised up higher and in a slightly larger font, just as it would be on a ruler. We can also see the numerals one through three to the right of that one inch marker. So, when reading the scale, we see that we have at least 1.3”

Moving on to the dial, we see that the needle is pointing above the numeral 40 and not all the way to the numeral 50. There are 10 marks between those two numbers, so we can count and see that we are at the seventh mark above 40, making a reading of 47. When we add that to our 1.3, we get a final reading of 1.347”.

Reading Vernier Calipers

Vernier calipers are even more complicated than dial calipers, in that the user must interpolate each of the numbers. There is no dial to give numbers, only a scale. The vernier part of this scale especially requires some understanding.

I do not have a vernier caliper to use for this article, but I do have other tools which use verniers, such as the depth micrometer above. This is somewhat different from a vernier caliper, in that the scale is wrapped around the handle, rather than straight, but the concept is the same. The diagram below shows how the scale on a vernier caliper would look.

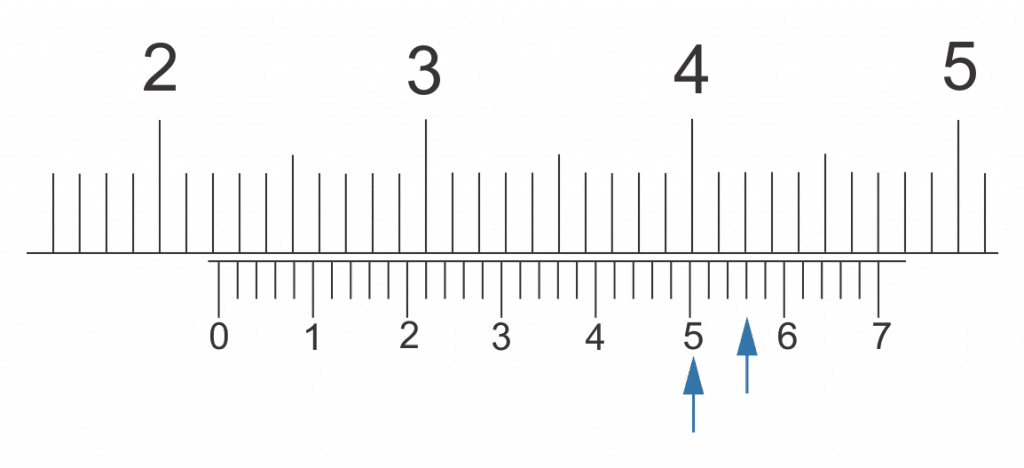

The first part of reading the vernier caliper is the same as it is with the dial caliper. In the diagram, the lower scale is the metric scale. We can see the numeral 2 showing, indicating 2 cm or 20mm. We can also see that the zero on the vernier scale is aligned with the fifth mark to the right of that 2 cm point. So the reading really isn’t 20mm, but 25mm. From there, we have to move on to the vernier to read tenths and hundreds of a millimeter.

The diagram below shows the vernier (taken from another diagram) of a set of metric vernier calipers. In this diagram, the zero is lined up with the second mark to the right of the number 2 on the main scale. Since the numbers in the main scale refer to centimeters, the zero is lined up with 22mm.

On the vernier scale, we have numbers, with lines between them, just like we do on the main scale. In this case, the numbers each refer to .1mm (tenths of a millimeter) and the lines between those numbers each represent 0.02 (two-hundredths of a millimeter).

We need to look for the tenths of a millimeter mark that comes closest to aligning with any of the lines on the main scale. In this example, that’s the number five, which is just about aligned with the number four on the main scale. So, the first number to the right of our decimal point is 4 (see the left of the two blue arrows above), making our reading 22.4mm. But we can go even more accurate than that.

To get our final number, we look at the marks between the number we’ve selected on the vernier scale and the next number on the scale. In this case, that’s the third mark. Since there are a total of five spaces between the marks with the numbers, we know that each of them is worth .02mm. the third mark is the one that aligns the best, so we know that our next number is 6 (see the rightmost of the two blue arrows above). This makes out final reading 22.46mm.

But what if none of those marks lined up perfectly? With verniers, it’s acceptable to select a point that is halfway between the existing marks, and call that the odd number that would be there, if there was a mark. That allows us to get down to a point of .01mm accuracy, even though the scale only shows 0.2mm of accuracy.