Plywood thickness ranges from 1/8 inch to over 1 1/4 inches, and choosing the correct thickness depends on span length, load requirements, framing spacing, moisture exposure, and long-term structural performance. For most residential and woodworking applications, 3/4-inch plywood is considered the standard because it balances strength, stability, and cost.

However, 3/4-inch is not always the right answer.

Using plywood that is too thin leads to sagging shelves, soft subfloors, cabinet box flexing, and long-term structural fatigue. Using plywood that is unnecessarily thick increases cost, weight, and labor without meaningful benefit.

In this complete guide, we’ll break down:

- Every plywood thickness and its best use

- Span and deflection logic

- 1/2″ vs 3/4″ vs 5/8″ comparisons

- Structural vs non-structural considerations

- Subfloor and roofing decisions

- 2026 cost breakdowns

- Product recommendations

- Mistakes to avoid

- Full internal linking cluster strategy

This guide is designed to be your definitive reference.

What Is Plywood Thickness?

Plywood thickness refers to the total measurement of all veneer layers bonded together under pressure to form a structural panel. Most plywood is sold in 4×8 sheets, but thickness varies.

Common nominal sizes:

- 1/8″

- 1/4″

- 3/8″

- 1/2″

- 5/8″

- 3/4″

- 1″

- 1 1/4″

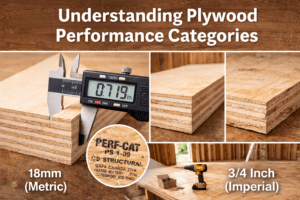

Important: Nominal thickness is not actual thickness.

Examples:

- 3/4″ plywood typically measures 23/32″

- 1/2″ plywood typically measures 15/32″

This difference matters when cutting dados, building cabinets, or installing tongue-and-groove subfloor.

Before choosing thickness, you should also understand different plywood types and grades, because material type affects strength alongside thickness.

How Plywood Thickness Affects Strength

Thickness directly influences:

- Load capacity

- Deflection (sag resistance)

- Screw holding strength

- Structural rigidity

- Long-term durability

The relationship between thickness and stiffness is exponential — not linear.

A small increase in thickness results in a significant increase in rigidity.

For example:

A 24-inch shelf made from:

- 1/2″ plywood → may sag under 40–50 lbs

- 3/4″ plywood → remains stable under the same load

Over time, even slight deflection weakens joints and fasteners.

Types of Plywood Thickness and Practical Use Cases

1/8″ and 1/4″ Plywood

Best for:

- Cabinet backs

- Drawer bottoms

- Decorative wall panels

- Underlayment

These sheets are not structural. They must be fully supported along edges.

Strength level: Very low

Cost: Low

Use case: Surface coverage only

3/8″ Plywood

Best for:

- Light paneling

- Backing layers

- Some sheathing applications

It offers slightly better stiffness than 1/4″, but rarely replaces 1/2″ in structural use.

1/2″ Plywood

Best for:

- Light cabinet sides

- Drawer components

- Wall sheathing

- Some subfloor patches

Strength level: Moderate

Span capacity: Limited

It works in certain builds, but for shelves wider than 20–24 inches, sag risk increases.

If you’re comparing material structure, see structural vs non-structural plywood.

5/8″ Plywood

Best for:

- Roofing

- Moderate subfloor systems

- Framing spaced 16″ on center

It offers noticeably better stiffness than 1/2″.

Common in roof decking where snow loads are moderate.

3/4″ Plywood (The Residential Standard)

Best for:

- Kitchen cabinets

- Bookshelves

- Garage storage

- Workbenches

- Subfloor

- Furniture builds

Strength level: High

Versatility: Excellent

If unsure, 3/4-inch is usually the safest and most durable choice.

For cabinet builds, review best plywood for cabinets.

1″ and Thicker Panels

Best for:

- Long unsupported spans

- Industrial storage racks

- Heavy-duty commercial builds

These are expensive and heavy but extremely rigid.

Thickness Comparison Table

| Thickness | Structural Strength | Shelf Span Capacity | Typical Use | Avg 2026 Cost |

|---|---|---|---|---|

| 1/4″ | Very Low | None unsupported | Backs & panels | $20–$30 |

| 1/2″ | Moderate | ~18–20″ | Light cabinets | $35–$50 |

| 5/8″ | Moderate-High | ~20–22″ | Roofing | $40–$60 |

| 3/4″ | High | 24″+ | Cabinets & shelves | $55–$85 |

| 1″ | Very High | 30″+ | Heavy storage | $90–$120 |

For regional pricing variation, see plywood prices.

1/2″ vs 3/4″ Plywood (Deep Comparison)

| Feature | 1/2″ | 3/4″ |

|---|---|---|

| Weight | Lighter | Heavier |

| Cost | Lower | Higher |

| Sag Resistance | Moderate | Strong |

| Screw Holding | Moderate | Excellent |

| Cabinet Durability | Fair | Excellent |

If building:

- Pantry shelves

- Garage racks

- Bookcases

3/4-inch reduces long-term deflection significantly.

The cost difference per sheet often averages $15–$25 — which is minor compared to rebuild costs.

5/8″ vs 3/4″ for Subfloor

Joist spacing determines required thickness.

16″ OC → 3/4″ recommended

24″ OC → 3/4″ minimum

For tile installation, rigidity is critical. Excess deflection leads to cracked grout.

See full subfloor preparation guide for installation best practices.

Cost Breakdown (2026 Market Reality)

Average Sheet Prices

- 1/4″ CDX → $20–$30

- 1/2″ BC → $35–$50

- 3/4″ Construction Grade → $55–$75

- 3/4″ Cabinet Grade → $65–$95

- 3/4″ Baltic Birch → $85–$120

- 3/4″ Marine Grade → $95–$140

Prices fluctuate based on lumber futures, housing starts, and region.

Project Cost Modeling

Kitchen Cabinets (14 sheets 3/4″ + 4 sheets 1/4″)

→ $900–$1,600 plywood cost

Subfloor Replacement (22 sheets 3/4″)

→ $1,200–$1,800

Garage Storage System (8 sheets 3/4″)

→ $500–$700

Outdoor Shed Walls (10 sheets 3/4″)

→ $600–$900

For exterior builds, always check moisture resistance in waterproof plywood.

Recommended Plywood & Tools

| Product | Thickness | Best For | Why It’s Recommended |

|---|---|---|---|

| Cabinet-Grade Birch Plywood | 3/4″ | Cabinets | Smooth veneer, stable core |

| Baltic Birch 13-Ply | 1/2″ | Drawer boxes | High screw holding |

| Marine Grade Plywood | 3/4″ | Outdoor builds | Waterproof adhesive bond |

| Structural T&G Subfloor Panels | 3/4″ | Flooring | Reduced deflection |

| Fine-Tooth Circular Saw Blade | — | Clean cuts | Reduces tear-out |

| Premium Deck Screws | — | Assembly | Strong holding power |

Tools Needed for Cutting and Installing Plywood

- Circular saw (fine-tooth blade)

- Table saw

- Carpenter square

- Tape measure

- Construction adhesive

- Deck screws (see best screws for plywood)

- Moisture meter (for subfloor builds)

Blade quality affects edge finish. A proper blade reduces tear-out and sanding time.

When Thicker Is NOT Better

Sometimes thicker plywood is unnecessary.

Examples:

- Cabinet backs (1/4″ sufficient)

- Decorative panels

- Fully supported surfaces

Overbuilding increases:

- Material cost

- Weight

- Installation time

Correct thickness is about matching load to performance.

Common Thickness Mistakes

- Using 1/2″ for 24″+ shelves

- Ignoring joist spacing

- Confusing nominal and actual size

- Using interior plywood outdoors

- Choosing thickness before considering span

If comparing alternatives, see plywood vs MDF.

FAQ

What plywood thickness is strongest?

1-inch plywood offers maximum rigidity, but 3/4-inch is standard for most structural applications.

Is 1/2-inch plywood strong enough for cabinets?

It works for light-duty cabinets, but 3/4-inch provides better long-term durability.

What thickness is best for shelves?

3/4-inch plywood is ideal for shelves up to 24 inches wide.

What plywood thickness is used for subfloor?

3/4-inch tongue-and-groove plywood is the residential standard.

Can thinner plywood be reinforced?

Yes. Laminating sheets or adding supports increases stiffness.

What’s the cheapest plywood thickness?

1/4-inch CDX is typically the lowest cost option.

Final Recommendation

If you are unsure, choose 3/4-inch plywood. It offers the strongest balance of cost, rigidity, and durability for most residential builds.

Always evaluate:

- Span distance

- Load weight

- Framing spacing

- Moisture exposure

- Budget

Choosing correctly prevents sagging, flexing, and costly rebuilds.