Have you ever tried to fix a wobbly chair leg with duct tape because you couldn’t find the “good glue”? Yeah—me too. Didn’t hold. That’s when I finally wised up and started keeping a bottle of PVA glue in the workshop at all times. Two, since I usually lose the first one.

If you’re into woodworking, crafts, or just fixing stuff when it breaks, this glue is probably already on your shelf. If it’s not, it should be.

So, What Exactly Is PVA Glue?

PVA stands for polyvinyl acetate, but no one calls it that unless they’re in a lab coat. For normal folks, it’s just white glue, wood glue, or “that bottle you grab when stuff breaks.”

It’s water-based. Dries clear. Smells mild. And sticks to stuff like wood, paper, cardboard, and fingers (usually when you least want it to). I first used it in grade school, and I’m still using it now—just on bigger messes.

Oh, and side note: if you accidentally leave it uncapped overnight? Yeah, it turns into a gummy rock. Ask me how I know.

Types of PVA Glue and How They Compare to Other Wood Glues

1. White Glue (a.k.a. Elmer’s)

You know the one. It lived in your backpack in 4th grade and probably exploded once.

- Great for: paper crafts, signs, quick fixes

- Washes off: easy

- Kid-safe: yep

🧴 I use Elmer’s Glue-All for labels, paper tears, and helping my kid build cardboard cities.

2. Wood Glue (The Yellow Stuff)

If you’ve ever fixed a drawer or clamped a picture frame, you probably reached for this.

- Great for: wood joints, trim, furniture fixes

- Needs clamping? Definitely

- Dries faster than you’d expect (sometimes too fast)

⚒️ Titebond III is my go-to. Waterproof, reliable, and it forgives bad cuts more than I deserve.

3. Archival / pH-Neutral Glue

This is the quiet MVP for delicate work. If you’re fixing old books or dealing with thin paper, this stuff won’t mess with the material.

- Great for: books, photos, important papers

- Acid-free: yes

- Dries flexible: thank goodness

📓 Lineco pH-Neutral Adhesive helped me patch up a century-old Bible. Held like magic.

Where I Use PVA (A Lot More Than I Thought I Would)

This glue has saved my bacon more times than I care to count:

- Loose table legs

- Molding that won’t stay put

- Random trim repairs

- Fixing that one drawer I keep slamming too hard

- DIY labels in the garage

And yes, I once glued the back of my hand to a board. Still not sure how.

Also, used it to fix a torn guitar case lining. Not its intended use, probably, but hey—it worked.

Easy DIY Projects (a.k.a. Excuses to Use More Glue)

| Project | Supplies | Glue Type |

|---|---|---|

| Birdhouse | Wood scraps, screws, clamps | Wood glue |

| Papier-mâché bowl | Newspaper, balloon, brush | White glue |

| Slime | Glue, baking soda, saline | White glue |

| Textured paint | Glue + sawdust | Wood glue |

Slime’s messy, but hey, the kids love it. Textured paint? Surprisingly cool.

You can also try gluing jute twine onto glass jars for custom organizers. Just don’t expect it to survive the dishwasher.

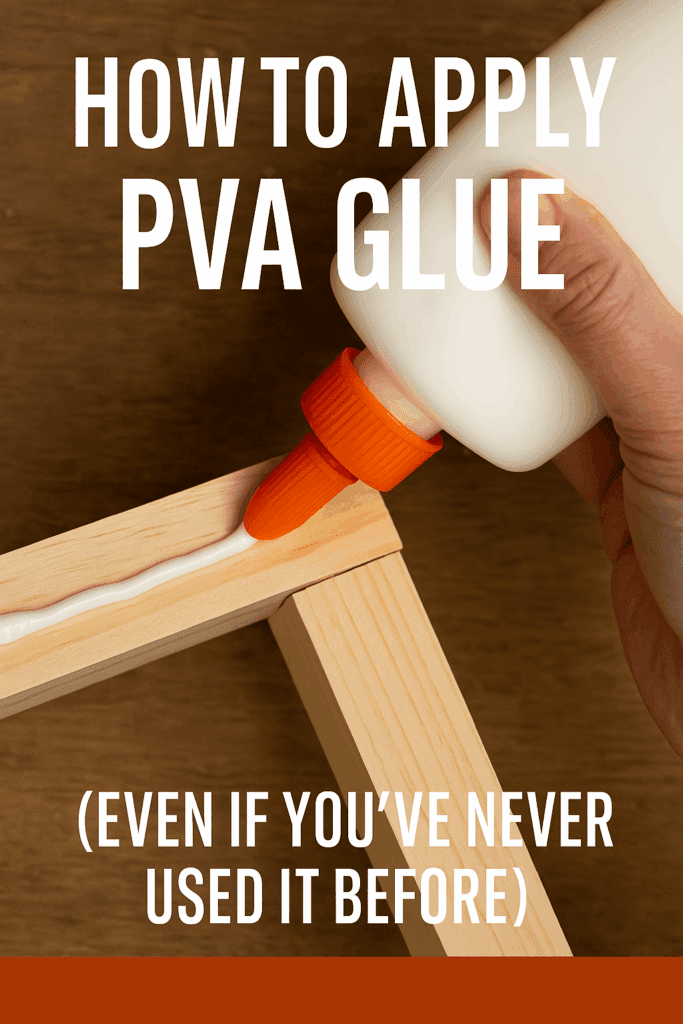

How to Use It Without Making a Mess

Here’s my system, if you can call it that:

- Clean surfaces—Dust, oil, and crumbs don’t help.

- Spread evenly—Brush, card, fingers (don’t judge).

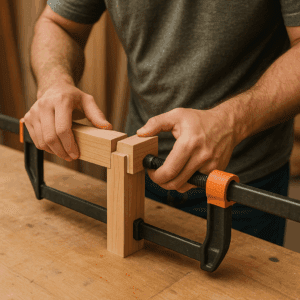

- Clamp or tape it—I’ve even used rubber bands in a pinch.

- Wipe squeeze-out right away—Dried glue = sanding party later.

- Don’t rush it—It might look dry in 20 minutes, but it ain’t.

Also? Don’t forget to label your clamps. I loaned mine to a neighbor who “forgot” to bring them back. Never again.

Drying Time (Reality Edition)

| Step | Time |

| Tack set | 10–15 min |

| Clamp time | 30–60 min |

| Full cure | 12–24 hours |

Pro tip: Cold garage? Everything takes longer. I once left a project to dry in winter, and it still wasn’t set by morning. Learned the hard way.

Also learned: trying to rush it with a heat gun doesn’t help. It just makes it bubble. Live and learn.

Storage Tips (Because Glue Bottles Are Weird)

- Store upright. Or the cap gets crusty.

- Don’t let it freeze. Ever.

- Stir if it thickens—a few drops of water usually fixes it.

- Smells sour? Toss it. It’s turned.

I date mine with a Sharpie. Keeps me honest.

Sometimes I even wrap the bottle cap with electrical tape to keep it sealed tight. It looks weird, but it works.

Is PVA Glue Waterproof?

Some of it. Not all. Big difference.

| Glue | Waterproof? |

| Elmer’s | ❌ |

| Titebond II | ✅ Water-resistant |

| Titebond III | ✅ Waterproof |

If it’s going outside, don’t gamble. Titebond III, every time.

I once glued a garden gate with the wrong kind and had to redo it a month later. Humidity = enemy.

Glue Showdown (For The Nerds Among Us)

| Glue | Use | Waterproof? | Flexible? |

| PVA | Wood, paper | Some | Yes |

| Epoxy | Metal, stone | Yes | No |

| Super glue | Plastics, fixes | No | No |

| Polyurethane | Foam, weird stuff | Yes | Sort of |

A Quick Word for Teachers and Parents

It’s safe. It cleans up. It doesn’t reek.

If your kid glues glitter to everything? At least it’s not permanent.

And yes, you can paint over it once it’s dry. (Ask me how I learned that.)

Also handy for science fair disasters, last-minute costume fixes, and classroom art that needs to survive a bus ride.

When NOT to Use PVA Glue (Yes, There Are Limits)

Okay, I love this glue—but it’s not magic. And it’s not for every situation.

Avoid PVA glue if:

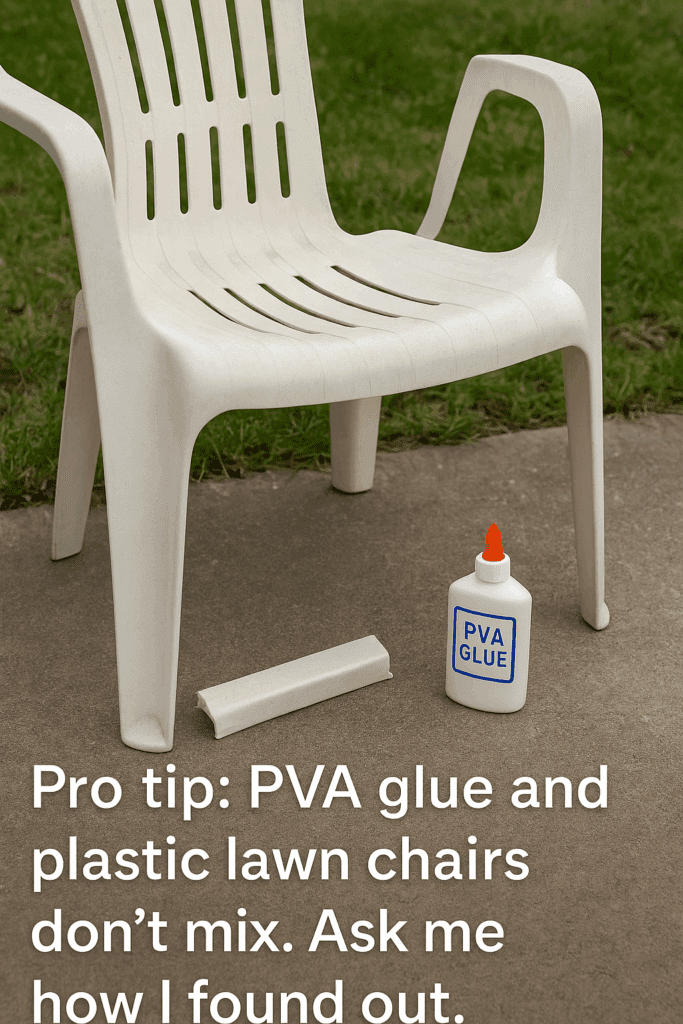

- You’re bonding metal or plastic. It just won’t hold up.

- You’re working somewhere that gets soaked (think: outdoor fences in monsoon season).

- The material is oily, nonporous, or slick (like HDPE or glass).

- You need fast-drying under stress—go with epoxy for that.

I once tried using PVA to fix a plastic lawn chair—total fail. Snapped right off the next time someone sat down. Lesson learned.

How to Tell If It’s Holding or Failing

Sometimes you just need to know: is this glued joint solid, or is it a ticking time bomb?

Quick checklist:

- Tight fit? PVA needs contact to work. Gaps = weak spots.

- Did you clamp it? If not, cross your fingers.

- Clean surfaces? Glue doesn’t like sawdust or hand grease.

- Did it cure long enough? 24 hours is safer than 6.

One trick I use: give it a knock test. If it sounds hollow or gives under thumb pressure, it’s probably not fully cured or bonded correctly.

If you ever need to take it apart again—good news: heat and moisture will break the bond. That’s a blessing and a curse, depending on the project.

Final Thoughts about PVA Glue

PVA glue is boring until you need it. Then it’s the star of the show.

I’ve fixed furniture, framed art, rescued books, and even made a few art projects that turned out better than expected.

If you’re doing any kind of hands-on project—whether you’re a woodworker, a crafter, or just someone tired of buying new stuff when it breaks—you need a bottle.

Make it two.

✅ Grab Titebond III on Amazon. Trust me—it’s worth it.