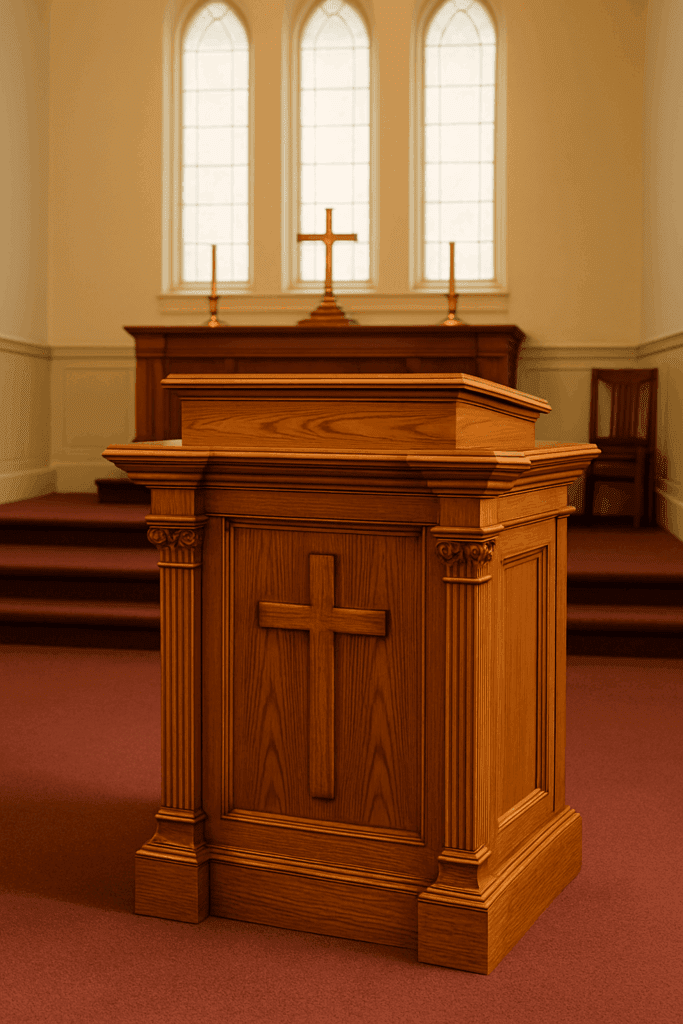

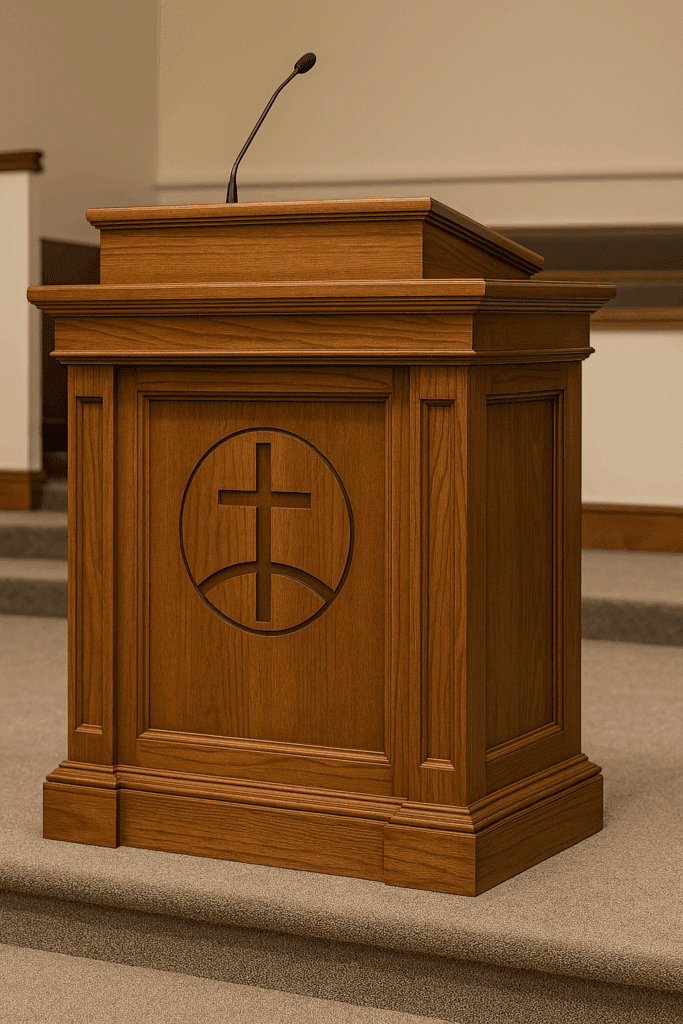

Step into any church, and your eyes are often drawn to one thing—the pulpit. More than furniture, it’s the place where powerful words are shared and faith is encouraged. And while buying a pulpit is easy enough, building one is an entirely different experience—one that’s filled with intention, creativity, and meaning.

I’ve worked on a few pulpits over the years, and each one was different—not just in design, but in the story it told. That’s why I’m sharing this guide: to help you build a wooden pulpit that reflects the spirit of your church and lasts for generations.

Why Build a Wood Pulpit?

In an age where you can buy just about anything online, building your pulpit might seem unnecessary. But here’s why it still matters:

- It means more. A handcrafted pulpit becomes part of your church’s legacy.

- You can make it your own. Customize it to fit your pastor’s needs and your church’s aesthetic.

- It saves money. Buying a custom pulpit can be costly—building one often costs half as much.

Wood also offers a classic look that acrylic or metal just can’t match. It brings warmth and gravitas to the sanctuary while being strong enough to handle years of weekly use.

Start with a Conversation

Before touching a single tool, talk with your pastor or the person who will use the pulpit most. What do they want? Maybe they need more space for notes or a built-in shelf. Getting clear on the must-haves makes planning—and building—a lot smoother.

Typical dimensions to start with:

- Height: 48 inches

- Width: 24–36 inches

- Top slope: around 15–20 degrees

- Depth: about 18–20 inches

You can always adjust these to fit your church’s space or pastor’s preferences.

Smart Features to Add

Over time, I’ve found that some features just make pulpits better:

- A sloped top with a lip to keep books or devices from sliding off

- A rear shelf for a water bottle or backup notes

- Holes for cable routing if you’re using microphones or lights

- Trim or front panels with a cross or custom logo

- Casters or hidden wheels if it needs to be moved often

These touches make a big difference in daily use—and they’re not difficult to build in.

Materials and Tools Checklist

Here’s what you’ll need:

Materials:

- 1 sheet of ¾” hardwood plywood (oak or birch is great)

- 1×3 or 1×4 boards for trim

- Wood glue, nails, screws

- Veneer edging (optional)

- Stain or clear topcoat

- Sandpaper or sanding blocks

Tools:

- Circular or table saw

- Drill and driver

- Clamps

- Iron (for applying veneer edging)

- Router (for detail work)

🛒 Recommended tools on Amazon:

How to Build It – Step by Step

- Cut your plywood: Start with the sides, front, top, bottom, and shelf. Use painter’s tape on your cut lines to reduce splintering.

- Install cleats: Glue and screw cleats inside the panels for extra strength where they meet.

- Assemble the body: Attach the sides to the front, then add the base and shelf.

- Add the top: Cut the top at an angle and attach a small lip across the bottom edge.

- Finish edges and trim: Apply veneer or hardwood trim to clean up the exposed plywood.

- Sand and stain: Fill nail holes, sand everything smooth, then apply your stain and finish.

Optional Extras That Add Real Value

If you’ve got a little more time and budget, consider adding:

- Lighting – A simple LED strip makes reading easier

- Power grommets – Add USB and power ports

- Hidden storage – A drawer or lockable shelf in the back

🛒 Great add-ons:

Common Challenges and How to Avoid Them

If you’ve never built a pulpit—or even a piece of furniture—don’t stress. Here are a few hiccups I’ve run into and how to handle them:

- Wobbly base? Check for floor-level issues first. Use adjustable feet to stabilize.

- Stain looks blotchy? Always test on a scrap piece and consider using a wood conditioner first.

- Panels not lining up? Clap dry fits before gluing. It’s easier to make adjustments beforehand.

- Rough veneer edges? Lightly sand and apply iron-on edge banding for a cleaner finish.

Taking your time makes a huge difference. I’ve rushed projects before and regretted it. The pulpit deserves patience.

From Workshop to Worship

The beauty of a DIY pulpit project isn’t just in the finished product—it’s in the story. Every screw and stain stroke becomes part of something bigger. You’re not just building wood into a shape; you’re building something sacred that will support sermons, weddings, baptisms, and more.

I’ve seen pulpits built on a shoestring budget that turned out more meaningful than any catalog version could ever be. With time, care, and a little sawdust, you can create something that will serve your church and touch hearts for years.