If you’ve ever needed a plywood that’s light, smooth, and visually appealing, without compromising on strength, Okoume plywood might be your new favorite material. Often used in boatbuilding, furniture making, and interior paneling, this tropical hardwood has found a special place in the world of woodworking. But what exactly is Okoume plywood, and why are so many builders choosing it over traditional birch or pine?

Let’s break down everything you need to know about Okoume plywood—its properties, applications, pros and cons, and the best tools and finishes to use when working with it.

📌 What Is Okoume Plywood Made From?

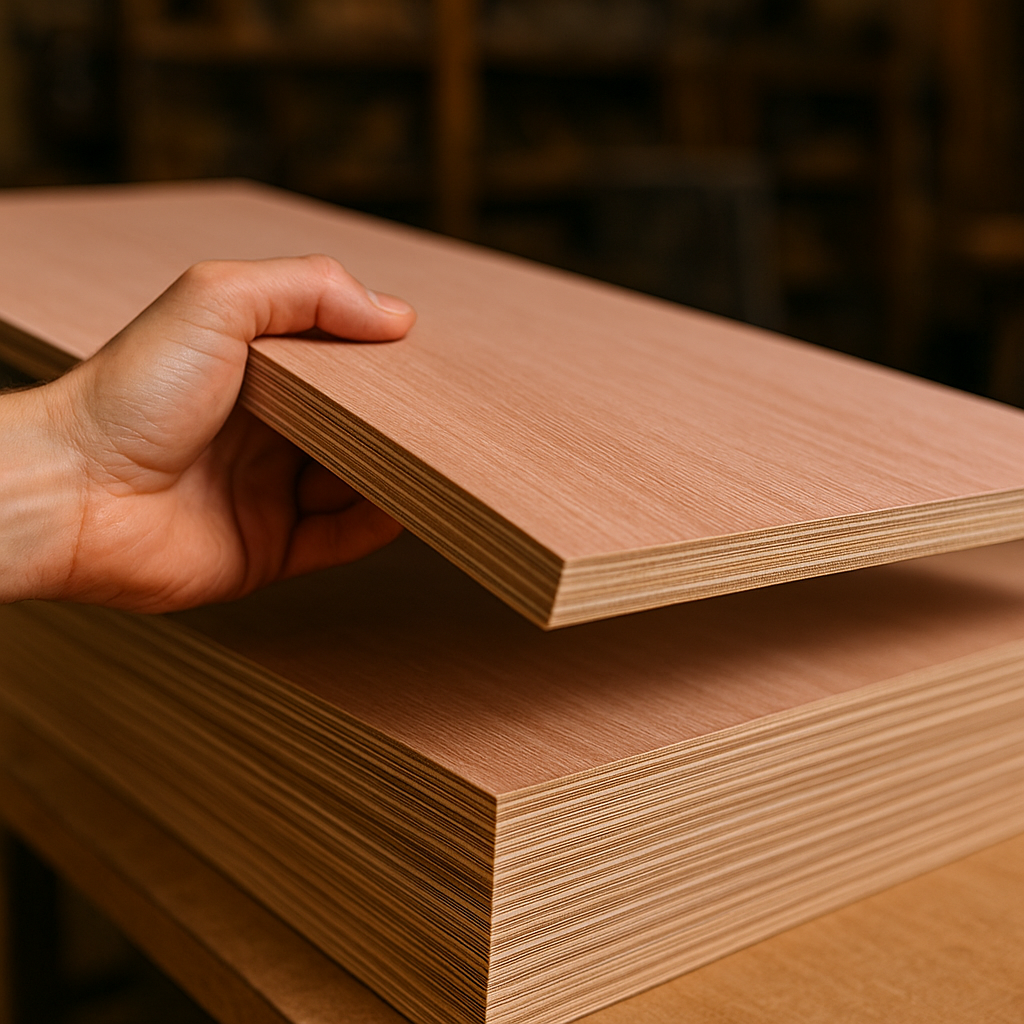

Okoume plywood is constructed from the wood of the Okoume tree, scientifically known as Aucoumea klaineana, which grows primarily in Central Africa, especially in Gabon. The wood is light pink to reddish-brown, with a subtle, ribbon-like grain.

Each sheet is made from multiple thin veneers of Okoume wood, cross-laminated and bonded with either interior-grade or marine-grade adhesives, depending on the product. Marine-grade Okoume plywood is especially valued for its water resistance and minimal voids, making it perfect for boat hulls and outdoor cabinetry.

🔍 Why Choose Okoume Plywood?

1. Lightweight Yet Strong

One of the standout features of Okoume is its weight. It’s significantly lighter than Baltic birch or hardwood plywood, making it ideal for projects where weight is a concern, like aircraft interiors, custom RV builds, and marine applications.

2. Beautiful Grain Pattern

Okoume’s grain is subtle but elegant. It finishes beautifully with clear coats or wood stains, which makes it a favorite for decorative furniture or paneling in high-end interiors.

🛠️ Common Uses for Okoume Plywood

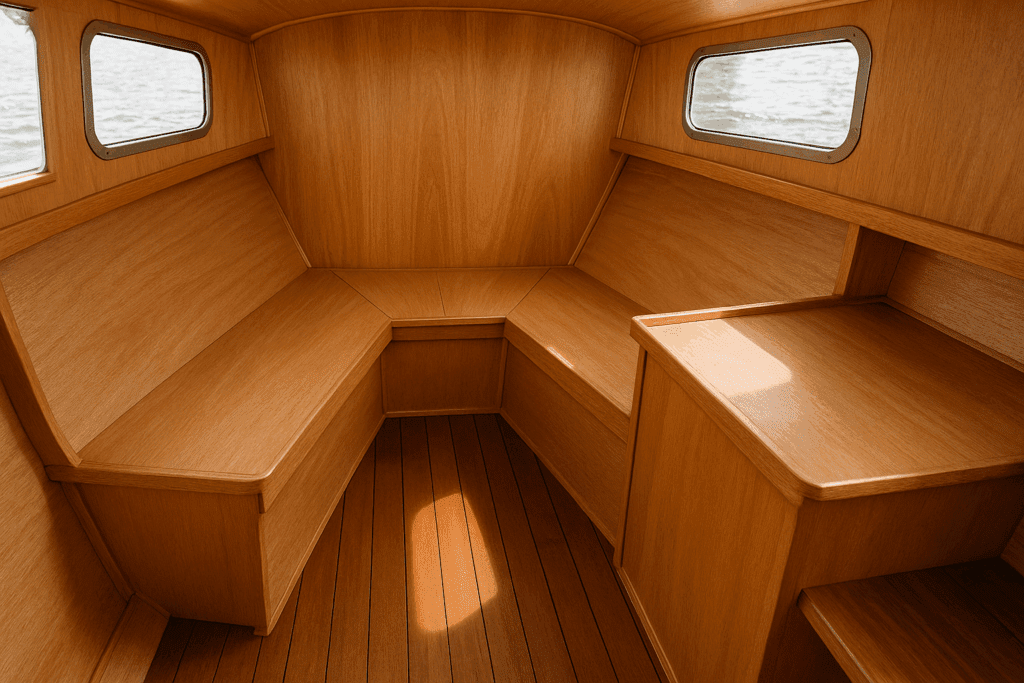

- Boat building: Especially in hull construction, due to marine-grade waterproof glues

- Furniture making: For lightweight yet stylish cabinets, drawer faces, and panels

- Van conversions & RV interiors: Perfect for reducing vehicle weight

- Home décor: Paneling, feature walls, or ceiling inlays

- Laminated cores: Okoume is often used under decorative veneers like teak or mahogany

⚖️ Okoume vs. Other Plywood Types

| Feature | Okoume | Baltic Birch | Maple Plywood |

|---|---|---|---|

| Weight | Very Light | Medium-Heavy | Heavy |

| Appearance | Soft grain, light pink | Light, even grain | Tight grain |

| Water Resistance | High (marine grade) | Moderate | Low (unless sealed) |

| Workability | Excellent | Good | Moderate |

| Cost | Medium to High | High | Medium |

🧰 Tools and Techniques for Working With Okoume

Okoume plywood is surprisingly forgiving. Because it’s a soft hardwood, it won’t wear down your blades too quickly. But being soft also means it can splinter if you’re not careful with your cuts.

🪚 Cutting Tips

- Use fine-tooth blades on circular or table saws

- Always cut with the face grain down to prevent tear-out

- Tape over the cut line to reduce splintering

🛠️ Recommended Tools

- Fine-tooth plywood blade for circular saw

- Orbital sander with variable speed control

- Carbide router bits set

🎨 Finishing Okoume Plywood

Finishing Okoume is a pleasure—it drinks up stains evenly and shines under clear lacquer or polyurethane. It’s often used as a core veneer under exotic finishes, too.

Finishing Steps:

- Sand to 220 grit with an orbital sander

- Apply wood conditioner to avoid blotching

- Use a water- or oil-based stain (if desired)

- Finish with 2–3 coats of polyurethane or marine varnish

Affiliate Product Picks:

🚫 Downsides of Okoume Plywood

While Okoume has many strengths, it’s not perfect for every situation.

- Soft Surface: It can dent or scratch more easily than hardwood plywood.

- Not Ideal for High Load-Bearing: For heavy shelves or structural framing, opt for stronger alternatives.

- Higher Cost: Marine-grade Okoume can be pricey, especially with quality certifications like BS 1088.

✅ How to Buy the Right Okoume Plywood

When buying, ask for:

- Marine Grade if water resistance is important (look for BS 1088 certification)

- Number of plies: More plies = better stability

- Core material: Some sheets have a mixed hardwood core for added strength

Quality, Size, and Thicknesses

Okoume wood is typically high quality, offering the same look as Okoume veneer products. Premium two-sided marine grade panels are normally 4’ x 8’, and are generally available in some thicknesses ranging from 2mm (1/8”) to 25mm (1”).

Okoume is a very soft wood, and plywood made with this resource is not normally pressure-treated. The composition may vary, with cores sometimes made with pine, poplar, or hardwood for added strength. Glues used in manufacturing this type of plywood include MR, E0, E1, E2, Melamine, and WBP.

Always inspect for:

- Minimal core voids

- Smooth face grain

- Consistent color and veneer thickness

Best Amazon Picks:

🌊 Is Okoume Marine Grade?

Not all Okoume plywood is marine grade. To qualify, it must:

- Be made with waterproof phenolic glue

- Have no core voids

- Use full Okoume plies throughout

- Pass boil tests and meet durability standards

Marine-grade Okoume is the gold standard for boatbuilding and exterior cabinetry—light, rot-resistant, and easy to shape.

🔧 DIY Projects You Can Build with Okoume

Here are a few lightweight, stylish projects:

- Floating wall shelves

- Drawer fronts and cabinets

- Wall paneling with oil finish

- Custom ceiling panels

- Teardrop trailer cabinetry

♻️ Is Okoume Plywood Sustainable?

Okoume trees grow fast, but overharvesting is a concern. Look for FSC-certified products or ask your supplier about sourcing practices. Using Okoume responsibly helps preserve rainforests and ecosystems in Central Africa.

🔚 Final Thoughts: Is Okoume Worth It?

If your project demands lightweight construction, attractive grain, and excellent workability, Okoume plywood is an excellent pick. Whether you’re building a boat, revamping a camper, or crafting high-end furniture, it’s a mix of beauty and performance that makes it stand out.

Just be sure to select the right grade and seal it properly, and your finished product will look stunning and last for years.