Walk into almost any kitchen or workshop, and there’s a good chance you’ll find Formica somewhere. It might be on a countertop, cabinet face, or even a custom-built workbench. Formica is one of those materials that quietly does its job well and lasts for decades. But if you’ve ever tried to cut or glue it without the right tools or methods, you know it can be frustrating. Chips, cracks, peeling edges—it’s enough to ruin a weekend project.

This guide shares everything I’ve learned over the years of working with Formica, from its background to step-by-step instructions for cutting and gluing it properly. Whether you’re resurfacing cabinets or building new countertops, this article will help you get professional results at home.

What Is Formica?

Formica is a brand name that’s become shorthand for decorative laminate sheets. Originally invented in 1912 as an electrical insulator, the name came from its original use: an alternative for mica.” These days, Formica is known for its durability, heat resistance, and design versatility.

It’s made by layering kraft paper, decorative paper, and melamine resin, which are then fused under intense heat and pressure. The result? A hard, durable surface about 1/16 inch thick that’s resistant to moisture, scratching, and staining.

Key benefits:

- Heat and moisture resistance

- Stain and scratch resistance

- Available in hundreds of textures and colors

🏠 Where You’ll Find Formica

Formica is incredibly versatile. Over the years, I’ve cut and glued Formica onto:

- Kitchen countertops

- Cabinet faces and doors

- DIY computer desks

- Workshop benchtops

- Coffee tables and TV stands

- Van and RV interior surfaces

Thanks to its durability and stylish finishes, it’s often used in both home improvement and commercial renovations. Matte Formica is great for workspaces, while glossy options shine in kitchens and bathrooms.

Where You’ll Find Formica

Formica isn’t just for kitchen countertops. Over the years, I’ve used it on:

- DIY desktops and home office surfaces

- Workshop benchtops

- Cabinet doors

- Tabletop repairs

- Custom van interiors

Thanks to a huge selection of colors and textures, you can match almost any décor style. Glossy finishes work great in kitchens, while matte surfaces are ideal for workspaces that need to resist glare.

Tools You’ll Need to Work with Formica

Cutting and gluing laminate successfully comes down to having the right tools on hand. Here’s what I recommend keeping close:

Cutting Tools:

- Fine-tooth jigsaw or circular saw

- Utility knife or scoring blade

- Straight edge or rip guide

For Gluing:

- Contact cement (brush-on or spray)

- J-roller

- Wood strips (for positioning)

Finishing:

- Router with flush trim bit

- Sandpaper (220-grit or finer)

- Masking or painter’s tape

Step-by-Step: How to Cut Formica Without Chipping

Here’s the method I use to get smooth, clean cuts every time:

1. Mark your cut line

Use a pencil and straightedge to measure and mark where you need to cut.

2. Apply painter’s tape over the cut

This helps prevent the laminate surface from chipping as you cut.

3. Score with a utility knife (optional)

For shortcuts, scoring deeply along the line can help snap the sheet cleanly.

4. Use a fine-tooth blade

Whether using a jigsaw or circular saw, make sure the blade is rated for laminate. I prefer reverse-tooth blades for the cleanest finish.

5. Cut slowly

Let the saw do the work. Rushing the cut leads to chips and splinters.

6. Finish with sandpaper

Smooth out any sharp or rough edges by lightly sanding them.

How to Glue Formica for a Professional Bond

Gluing Formica is all about surface prep, timing, and pressure. Here’s my go-to process:

1. Cut the laminate oversized

Always cut your sheet larger than your project base—you’ll trim it down later.

2. Apply contact cement

Use a brush or roller to apply an even coat of adhesive to both the substrate (plywood or MDF) and the back of the Formica.

3. Let it dry until tacky

Wait about 20–30 minutes until both surfaces feel dry but sticky to the touch.

4. Use wood strips as spacers

Lay thin strips across the substrate and place the laminate on top. This prevents accidental sticking.

5. Position carefully

Once it’s aligned, remove the strips one at a time and press the Formica down.

6. Roll with a J-roller

Apply firm, even pressure across the surface to bond everything together.

7. Trim the edges

Use a flush-trim router bit to remove the excess.

Can You Install Formica Over Existing Laminate?

Yes, but it depends on the condition of the old surface. I’ve done it a few times successfully, but there are some important caveats:

✅ It works if:

- The existing laminate is smooth and well-bonded

- You scuff-sand the surface first for grip

- You use a strong contact cement

❌ It won’t work if:

- The old laminate is peeling or cracked

- The surface is greasy or contaminated

- It has a rounded bullnose or drip edge

If in doubt, remove the old sheet. It’s more work, but it ensures a longer-lasting bond.

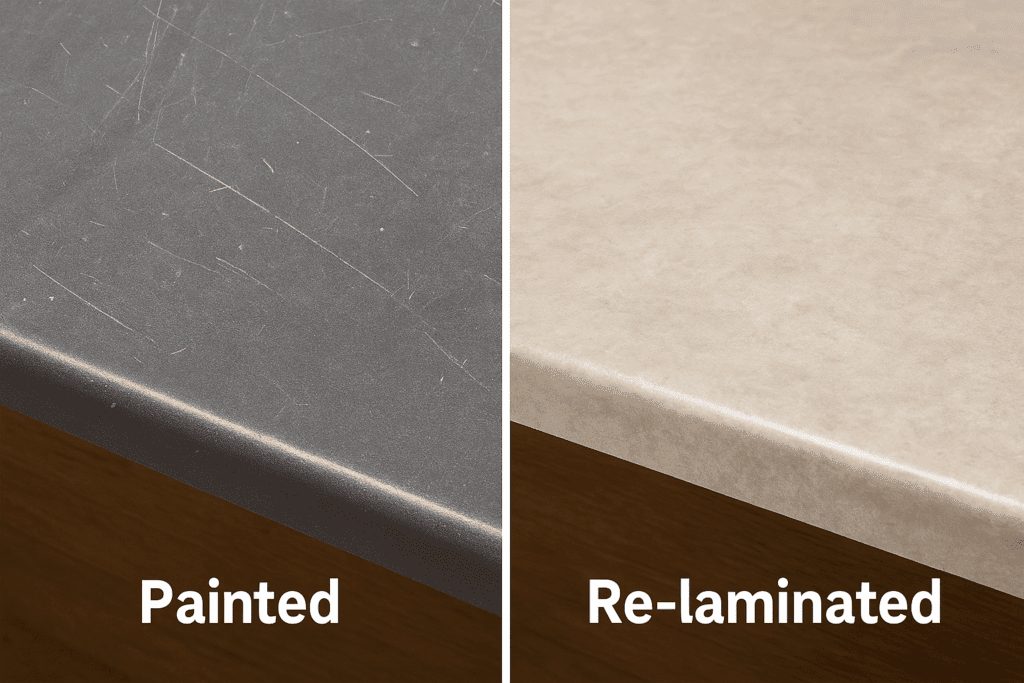

Should You Paint Formica Instead?

I get this question a lot—and here’s my honest answer: You can paint Formica, but I rarely recommend it.

Why? Even with primer and sealing, painted laminate is prone to:

- Peeling and bubbling from heat or moisture

- Scratching during daily use

- Losing its clean finish over time

If your goal is a long-lasting upgrade, re-laminating with Formica is a much better route.

Troubleshooting Common Formica Problems (And How to Avoid Them)

Even with the best tools and a careful hand, things can go wrong when working with Formica. Whether it’s bubbling, lifting edges, or rough seams, these common issues can make your project look less than professional. After years of working with laminate, I’ve picked up a few reliable fixes—and even more importantly, how to prevent these problems in the first place.

Bubbling or Air Pockets After Gluing

This happens when air gets trapped between the laminate and substrate—or when the adhesive wasn’t applied evenly. If you’re seeing bubbles or soft spots, you may be tempted to press down harder or pop the bubble with a pin, but that rarely fixes the issue permanently. Instead, use a J-roller during initial bonding, applying strong, even pressure across the entire surface. Start at the center and work outward. If the bubble is already there, try heating it slightly with a clothes iron (on low, with a cloth barrier) and re-rolling. It works surprisingly well in many cases.

Peeling Edges or Corners

Corners and edges tend to lift if the adhesive didn’t cure properly or if you didn’t apply enough pressure during installation. To avoid this, always let the contact cement become tacky before bonding—and be generous with the J-roller, especially near the edges. If the edges still peel later, you can re-apply contact cement and press it down again with a wood block or clamp until it holds. Avoid using super glue—it can leave a white haze and doesn’t flex with temperature changes.

Chipped or Cracked Laminate

This usually occurs during cutting. Using a dull blade, the wrong type of saw, or cutting too quickly can all cause the laminate to chip. Make sure to use a reverse-tooth jigsaw blade or a laminate-rated circular saw blade. Also, don’t skip the painter’s tape over your cut line—it cushions the surface and helps reduce splintering. If you do get a small chip, you can often hide it with a matching laminate repair paste or touch-up marker.

Visible Seams Between Sheets

If you’re butting two sheets together—like across a large countertop—you may end up with a visible seam. While some visibility is expected, the key is minimizing it. Use sharp blades, trim carefully, and always line up patterns or grain directions. Seam filler kits or color-matched caulk can help disguise minor seams. When possible, plan your cuts so seams are in less noticeable areas.

Contact Cement Not Sticking

If the glue seems to fail after just a few days, the most likely culprit is poor surface prep. Always clean both surfaces thoroughly—no sawdust, oil, or moisture. Also, check the expiration date on your contact cement; old cement may not bond well. I also recommend doing your work in a well-ventilated, warm environment. Cold temperatures or high humidity can interfere with adhesion.

My Go-To Products for Cutting and Gluing Formica

These are tools I’ve used regularly and can vouch for personally:

Cutting:

- DEWALT 20V MAX Jigsaw – Great for detailed laminate cuts

- Bosch T101BR Reverse-Tooth Blades – Prevents surface chipping

- IRWIN Utility Knife – For scoring clean snap lines

- Kreg Rip-Cut Guide – Ensures dead-straight circular saw cuts

Gluing & Finishing:

- DAP Weldwood Contact Cement – Industry standard for laminate

- 3M ScotchBlue Painter’s Tape – Prevents chips while cutting

- Laminate J-Roller – For firm, even pressure

- DEWALT Router with Flush Trim Bit – For perfect edge finishing

Final Thoughts: Is Formica Worth It?

In a word, yes. Formica is budget-friendly, highly durable, and now comes in designs that mimic wood, marble, and even concrete. If you take the time to prep your surfaces, cut carefully, and glue with patience, the results are better than anything you’d get from a cheap replacement counter.

Working with Formica isn’t just for contractors. With the right gear and a little guidance, it’s a perfect DIY weekend project.

📌 Bonus: [ free printable Formica installation checklist]

— includes tools, steps, and tips you can bring to the shop or jobsite.