Protecting your handmade wood furniture is just as important as crafting it. A single hot dish or a cold drink can leave behind lasting damage like water rings or burn marks. Sure, refinishing a table is possible—but who wants an extra project? That’s where coasters and trivets come in handy. In this extended guide, we’ll dive deeper into multiple ways to make wooden coasters—from rustic live-edge styles to polished resin-infused creations—and how to finish and protect them properly.

Why Use Wood for Coasters?

Wooden coasters aren’t just functional—they add warmth and style to any setting. They complement a wide range of décor, from farmhouse rustic to modern minimalist. Whether you’re crafting them to match existing furniture or to gift someone a custom piece, wooden coasters offer endless design potential.

They also allow creative freedom—carving, staining, engraving, or combining wood types gives you control over the final look. Unlike plastic or cork, finished wood handles heat, moisture, and wear with elegance.

🔗 Explore more: Best Wood Finishes for DIY Projects

🔗 Also read: Plywood Grades Explained

Common Woods for Coasters: Best Species to Use

Choosing the right wood species plays a huge role in the durability and appearance of your coasters. Some woods are too soft, while others may split easily or resist finish absorption.

Top Wood Choices:

- Walnut: Rich color, easy to finish, beautiful grain

- Cherry: Ages beautifully, medium hardness

- Maple: Extremely durable, smooth texture

- Oak: Prominent grain and high strength

- Padauk/Purpleheart: Exotic colors for contrast

Avoid woods like pine, which are too soft and prone to denting.

🔗 Deep dive: Best Plywood for Cabinets and Furniture

Workshop Setup and Safety Tips for Making Coasters

Crafting coasters might seem simple, but having a smart, safe workspace makes the experience smoother and your results more consistent. Whether you’re working on a fold-out bench in your garage or a full-blown woodworking studio, it pays to deliberate how your space is arranged.

Start by clearing a large, flat surface for cutting and assembly. Even a kitchen table can work with a protective mat and some clamps. For those with more dedicated setups, a heavy bench with bench dogs or a quick-release vise can make tasks like sanding or chiseling more secure. Keep your most-used hand tools—like a square, pencil, sanding block, and small clamps—within arm’s reach. A magnetic strip or pegboard can help organize without cluttering your surface.

When it comes to power tools, safety starts with stability. Make sure your router, bandsaw, or drill press is firmly anchored and well-lit. Shadows can hide hazards. Natural daylight is best, but LED shop lights mounted over your bench work wonders for late-night builds or dim basements. Consider a small, portable dust collector or even a box fan with a furnace filter taped to the back for a DIY air cleaner. Wood dust—especially from MDF—can linger and irritate your lungs long after you’re done working.

Divide your workshop into zones: a cutting area, sanding station, gluing zone, and finishing corner. Each should have its own drop cloth or waste bin. For example, finishing the application benefits from a clean surface free of sawdust. Line your finishing station with parchment paper or an old silicone baking mat. Elevate your coasters on painter’s triangles or bottle caps to prevent sticking while drying.

Protect yourself with goggles, a dust mask (or better, a respirator), and ear protection if you’re using noisy machines. If you’re mixing epoxy or using a heat gun, wear gloves and work in a space with good ventilation. Store a fire extinguisher nearby, especially when working with flammable finishes or using open flame to pop bubbles in resin. Keep cords tidy and avoid working near water sources unless you’ve got GFCI outlets.

Lastly, add a little comfort: a stool with good back support, a rubber mat for tired feet, or a Bluetooth speaker for your favorite woodworking podcast. A thoughtful workspace doesn’t just keep you safe—it helps you enjoy the process, which ultimately makes your coasters turn out better.

Cutting Techniques for Consistent Shapes

Precision in cutting leads to consistent coasters, especially if you’re making sets. Here are popular tools and techniques:

For Straight Cuts:

- Use a table saw with a sled for perfect squares

- Set a stop block for repeatable cuts

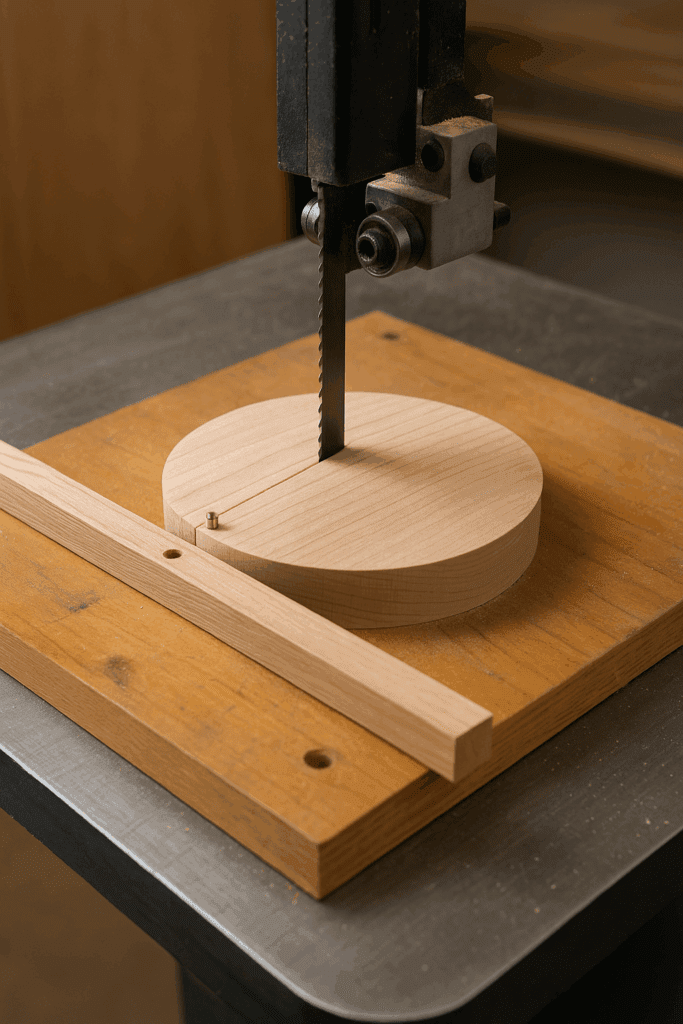

For Round Coasters:

- Bandsaws with circle-cutting jigs

- Hole saws (for small batches)

- CNC routers (for bulk production)

Always mark your center lines and secure the material properly.

Sanding Tips for a Smooth, Professional Finish

After cutting, your coasters need thorough sanding. Here’s a breakdown:

Tools:

- Belt sander for flattening faces

- Random orbital sander for final smoothing

- Sanding block for edges

Recommended Grits:

- Start at 80–100 grit (shaping)

- Move to 150–180 grit (smoothing)

- Finish at 220–320 grit before applying the finish

Between coats of varnish or polyurethane, use 320–400 grit for leveling.

🔗 Sanding advice: How to Make Plywood Look Nice

Decorative Edge Options

Edge profiles make your coaster look finished and polished.

Options Include:

- Chamfer (angled edge) using router or sander

- Roundover with a 1/8″ or 1/4″ router bit

- Cove or ogee bit for more ornate looks

If you’re going for a rustic look, hand-sanding the edges unevenly can give a natural, hand-hewn feel.

Sealing Coasters for Outdoor or High-Moisture Use

Most people use coasters indoors, but if you’re making some for patio tables or high-humidity areas, consider these tips:

Best Sealants:

- Marine spar urethane

- Exterior-grade polyurethane

- Epoxy (full coverage)

Apply multiple coats and let each cure fully. Add felt or rubber feet to keep them off wet surfaces.

🔗 Check out: DIY Outdoor Wood Projects

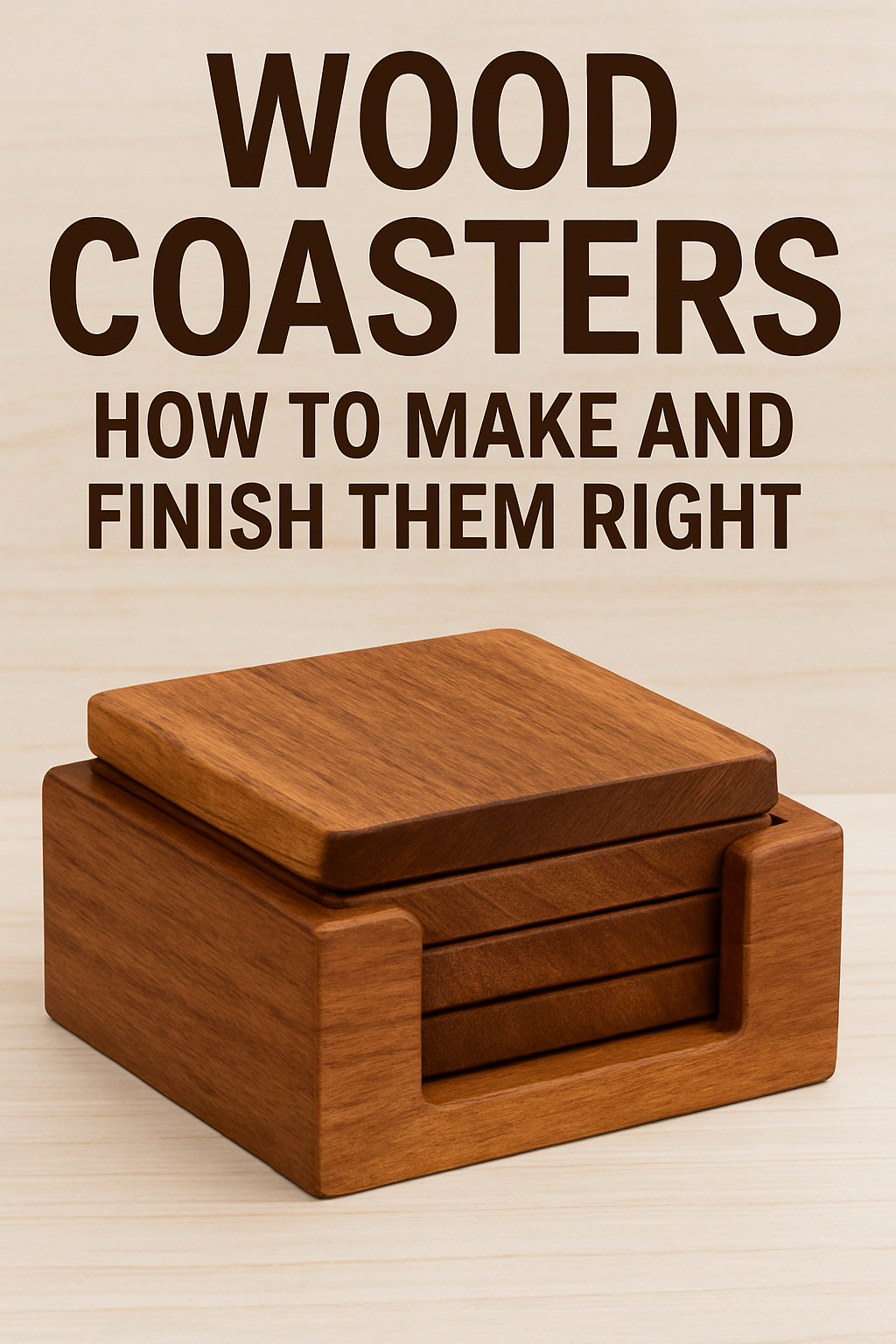

DIY Coaster Holder Ideas

If you’re making a gift set or planning to sell coasters, a matching holder adds value and appeal.

Quick Builds:

- Simple Box: Basic square or rectangle with routed finger grooves

- Slotted Stand: Vertical dividers for organizing coasters upright

- Round Holder: Turned bowl with coaster-sized cavity

Selling Wooden Coasters: Etsy, Craft Fairs & Beyond

Wood coasters are a fantastic entry product for selling at local craft markets or online. Here’s what you need to know:

Popular Sets:

- 4–6 matching coasters in a gift box

- Themed sets: holidays, initials, animals, quotes

Tips:

- Add branding with stamps or laser engravings

- Include care instructions

- Offer bulk pricing for weddings or corporate gifts

🔗 Marketing help: Wood Projects That Sell

Creative Variations: Beyond Standard Coasters

Don’t be afraid to get creative with your coaster projects. Here are a few unique ideas:

- Puzzle Coasters: Each piece connects to form a larger image

- Glow-in-the-Dark Epoxy Lines

- Cork Inlays: Wood frame with cork center

- Leather and Wood Hybrids: Add stitched leather to walnut bases

- Themed Coasters: Route in state shapes or geographic outlines

DIY Coaster Kits and Gift Packaging

Want to make your handmade coasters feel even more premium? Add custom gift packaging or offer DIY kits for sale.

DIY Kits Should Include:

- 4–6 blank wooden discs or squares

- Sandpaper (220+ grit)

- Small bottle of finish or oil

- Instructions and branding info

Gift Packaging Options:

- Kraft boxes with wood excelsior

- Laser-cut boxes with logo engraved

- Twine, tags, or mini wax seals for rustic appeal

Troubleshooting Common Issues

Problem: Coasters warp after finishing

Fix: Apply equal coats to both sides and let dry flat with weight on top.

Problem: Resin bubbles form during curing

Fix: Use a heat gun or torch lightly after pouring to remove air bubbles.

Problem: Bark falls off live-edge coasters

Fix: Use a deep-pour epoxy to seal the bark before slicing or reinforce after.

Problem: Finish stays tacky

Fix: Ensure drying environment isn’t too humid or cold; thin coats are key.

Final Thoughts

From rustic live-edge designs to elegant resin mosaics, wooden coasters are a satisfying DIY project for woodworkers of all skill levels. They offer style, protection, and functionality—and make great gifts, too. With all the design possibilities and market appeal, they’re also a smart option for turning woodworking into profit.

Want more woodworking project ideas?

🔗 Check out: Weekend Woodworking Projects