When I first wandered into the lumberyard hunting for walnut plywood, I didn’t expect to be so distracted. The piles of sheets looked almost too good to touch. Compared to the pale birch and maple stacked nearby, these panels had a richness that immediately stood out. The dark brown tones and swirling grain made me think about how many projects I could tackle—probably more than my little pickup could haul.

What surprised me later was realizing that walnut plywood isn’t just about looks. It’s a practical choice. You get the style of solid walnut without having to pay the premium price. For projects like cabinets, shelves, furniture, or even wall accents, it delivers that same warm character at a fraction of the cost.

Over time, I’ve picked up a handful of lessons (some the hard way) about using it. In this guide, I’ll walk you through the basics: what walnut plywood actually is, how much you can expect to spend, the best places to find it, and tips I’ve learned to avoid costly mistakes.

What Exactly Is Walnut Plywood?

At its core, walnut plywood is simply a sheet of plywood with a thin walnut veneer on the face. Underneath, the core can be made from hardwood, softwood, or MDF. That veneer is what gives the panel its rich walnut look, while the layered construction makes it stable and resistant to warping.

- Color and grain: Natural walnut ranges from dark brown to purplish gray, often with a subtle wavy or curly pattern.

- Sizes: Standard 4×8 sheets are most common, but smaller project panels are also available.

- Thickness: Ranges from 1/4″ for drawer bottoms to 3/4″ for furniture.

In short, walnut plywood offers the aesthetics of hardwood walnut with the stability of engineered wood.

Why Builders and DIYers Love Walnut Plywood

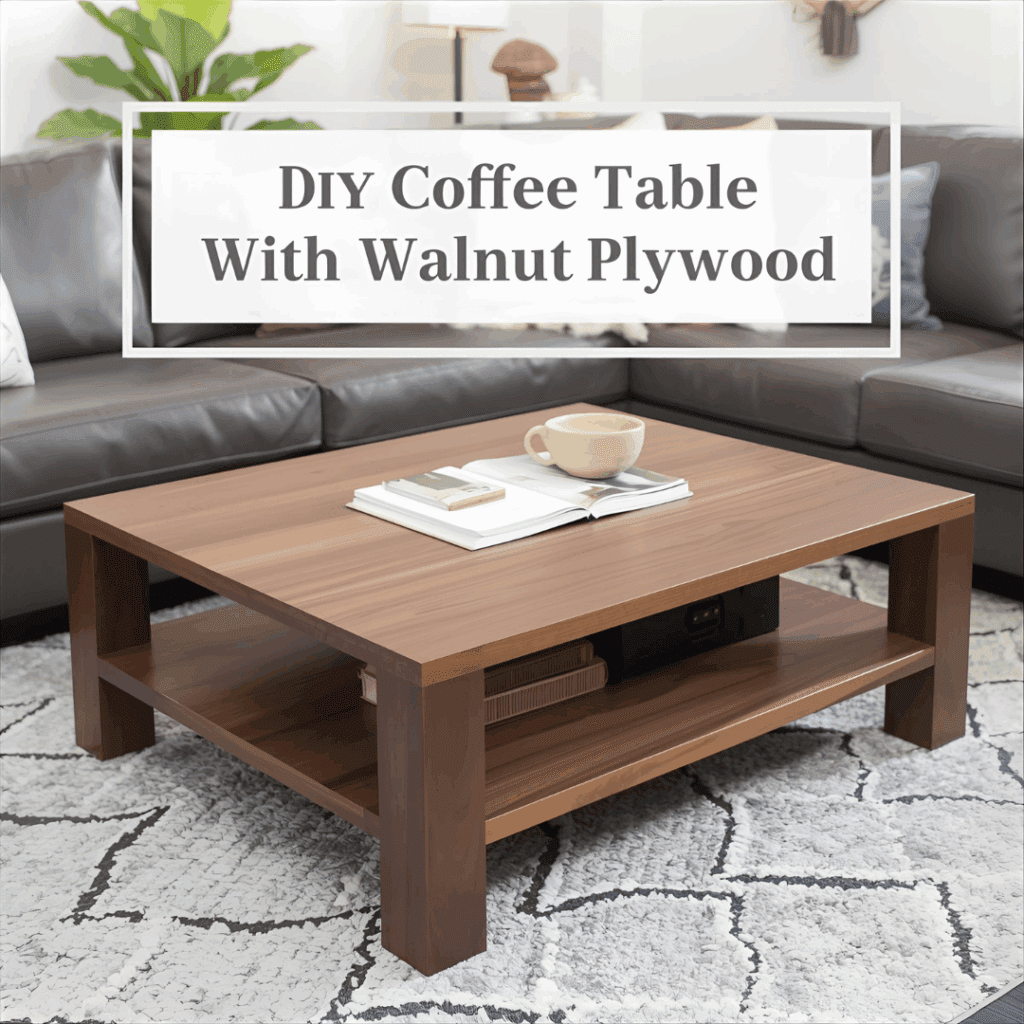

The first time I used it was for a coffee table. I couldn’t afford solid walnut boards, but I wanted the table to have that warm, luxury feel. Plywood turned out to be the sweet spot—it looked high-end without draining my budget.

Here’s why so many people choose it:

- Affordable luxury – A 3/4″ walnut plywood sheet costs far less than the same surface area in solid walnut.

- Stability – Unlike solid wood, plywood is less likely to warp, cup, or split.

- Workability – Cuts and sands easily with common woodworking tools.

- Eco-friendly – Since only a thin slice of walnut is used, less hardwood is consumed.

Common Uses for Walnut Plywood

You’ve probably come across walnut plywood more often than you realize—it shows up in homes, offices, and even small weekend projects. Here are some of the ways it’s most often put to work:

Cabinets and Built-Ins

Whether it’s kitchen cabinets, a bathroom vanity, or custom shelving, walnut-faced panels give any room a sophisticated upgrade. I’ve noticed that even a simple cabinet door swap can make a dated kitchen feel completely new.

Furniture Making

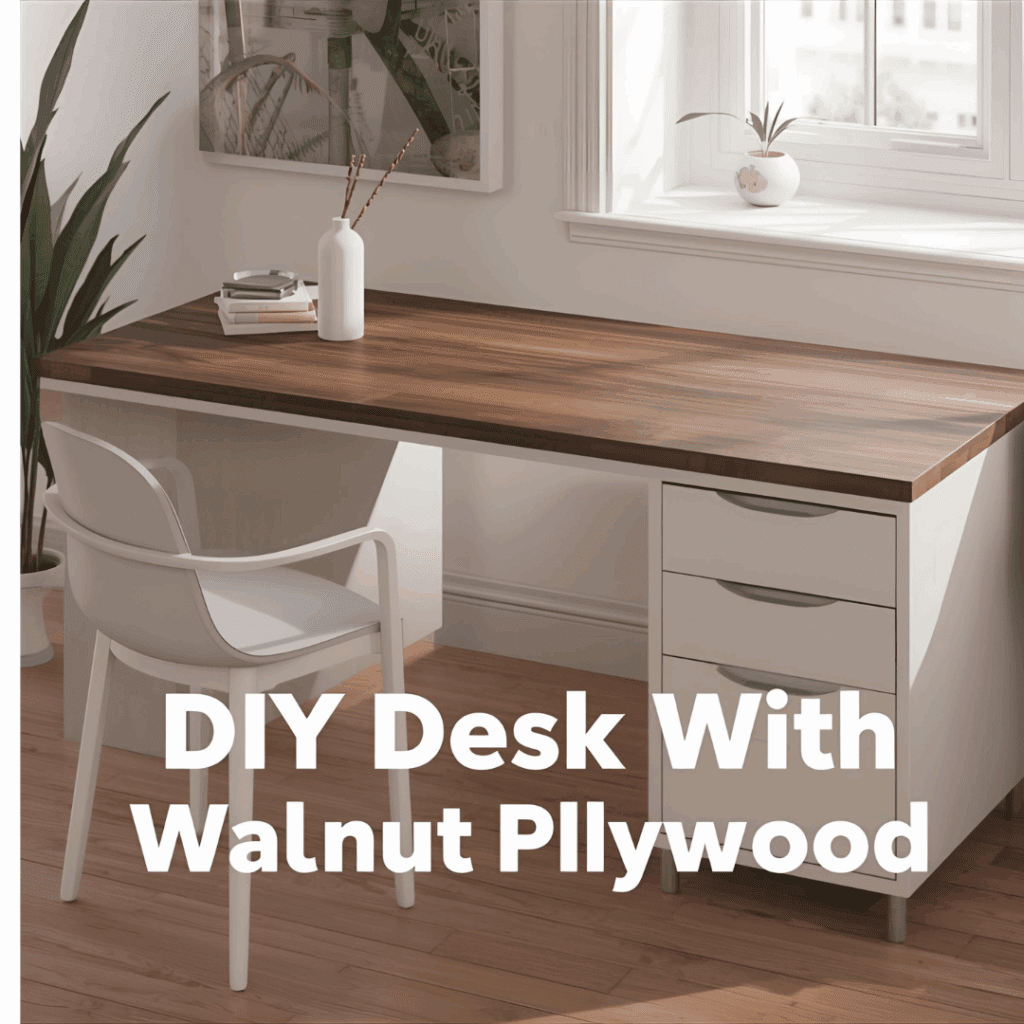

From modern desks to mid-century dressers, plywood with walnut veneer is a furniture maker’s favorite. It’s lighter than solid boards but still strong enough for daily use, which makes it easier to move a finished piece without calling in extra help.

Wall Paneling and Ceilings

I once installed walnut sheets behind a bed as a feature wall, and the change was dramatic—the space felt warmer and more inviting. Guests often asked about it because the walnut instantly became the focal point of the room.

Shelving and Bookcases

Floating shelves made from walnut veneer plywood not only hold plenty of weight but also double as eye-catching décor. In my own home office, I built a set to display books and plants, and they still get compliments years later.

DIY Projects

Small builds like jewelry boxes, speaker cabinets, or cutting boards benefit from the walnut look without burning through full hardwood boards. I’ve even used scrap pieces for picture frames, and the results were far nicer than I expected.

Walnut Plywood vs. Other Hardwood Plywoods

How does walnut plywood stack up against other popular species?

Birch: It’s strong and easy on the budget, but the color is much lighter than walnut. I usually reach for it when I need sturdy panels for shop cabinets or hidden structural work.

Maple: Very smooth and pale, with a clean modern look, though it doesn’t have the depth you get from walnut. A lot of people like it in kitchens or built-ins because it brightens up the space.

Oak: Tough and rustic, with an open grain that feels less polished. I’ve used it for farmhouse-style furniture, and it holds up well, but it doesn’t give off the same refined vibe that walnut does.

If your goal is luxury and warmth, walnut usually comes out on top.

Cost of Walnut Plywood

What you’ll pay depends on the thickness, grade, and even the store, but here’s a rough guide:

- 1/4″ sheets usually run $45–$60

- 1/2″ sheets fall around $70–$95

- 3/4″ sheets often land between $100–$160

It’s more expensive than birch or oak, but still comes in well under the price of solid walnut boards.

How to Work With Walnut Plywood

After ruining my first sheet by sanding through the veneer (lesson learned), I’ve picked up a few tips worth sharing:

- Cutting – Use a sharp blade, preferably a plywood blade, and apply painter’s tape on the cut line to avoid splintering.

- Edging – The exposed core layers don’t look good. Apply walnut edge banding for a clean, solid-wood look. Iron-on walnut edge banding on Amazon works great.

- Sanding – Go lightly with 220 grit. The veneer is thin, so don’t overdo it.

- Finishing – A clear polyurethane or Danish oil really brings out the natural walnut tones.

Best Finishes for Walnut Plywood

The right finish can make or break your project.

- Clear Polyurethane – Durable and enhances the natural look.

- Danish Oil – Easy to apply and gives a warm, hand-rubbed finish.

- Shellac – Adds a soft glow, but is less protective.

- Stains – You can deepen the tone, but walnut usually looks great as-is.

👉 Top finishes for walnut on Amazon.

Pros and Cons at a Glance

Advantages:

- Rich, elegant appearance – The dark tones instantly give projects a high-end look, even if the design itself is simple.

- Stable and strong – Because of its layered core, it holds up well in environments where solid walnut might warp.

- More affordable than solid walnut – You get the look without draining your wallet on expensive hardwood boards.

- Lighter weight for furniture making – It’s easier to move finished pieces around without needing a second set of hands.

Drawbacks:

- Thinner veneer can be damaged if over-sanded – Once you sand through, there’s no way to repair the face without replacing it.

- Higher cost compared to birch or oak plywood – It can feel like a splurge if you’re building a large project on a tight budget.

- Not always available at big-box stores – You may need to visit a specialty lumberyard or order online to find good sheets.

Where to Buy Walnut Plywood

- Local lumberyards – This is usually where I start. The sheets are often better quality, and the prices are fairer than what you’ll find at a big-box store.

- Specialty wood shops – Stores like Rockler or other woodworking suppliers tend to carry premium walnut veneer if you’re after top-grade panels.

- Online sources – Ordering online is convenient, but the shipping costs can add up fast, especially on full sheets.

For smaller builds, I’ve even picked up pre-cut walnut plywood panels on Amazon, which worked fine when I didn’t need a whole 4×8 sheet.

Tips for Choosing the Right Walnut Plywood

Not all walnut plywood is created equal, and choosing the right sheet can save you frustration later on. The first thing I check is the grade of the veneer. “A” grade faces look flawless and are best for furniture or cabinets where the wood is visible. “B” or “C” grade sheets might have minor imperfections, which can be fine for backs, drawer bottoms, or hidden areas.

Next, I always look at the core material. Hardwood cores are stronger and hold screws better, while MDF or particleboard cores are smoother but not as durable. If you plan on doing detailed edge work, hardwood cores are worth the extra few dollars.

Finally, take a close look at the veneer thickness. Some budget panels have an extremely thin face layer that’s easy to sand through by mistake. Spending a little more for a thicker veneer can extend the life of your project and give you peace of mind when finishing.

Project Ideas With Walnut Plywood

Looking for inspiration? Here are a few projects where walnut really stands out:

- Mid-century modern coffee table with metal legs – I’ve seen a lot of these lately, and the walnut veneer really makes the simple design pop.

- Floating shelves with edge banding – A clean way to add both storage and style without spending a fortune.

- A sleek walnut desk with drawers – Practical for daily use, and the dark tones give it a professional look.

- A headboard made from book-matched walnut panels – Works great if you want a bold, one-of-a-kind bedroom feature.

- Wall art panels or speaker enclosures – Small builds that still show off the depth and grain of walnut veneer.

Caring for Walnut Plywood Projects

Walnut veneer projects can last decades if maintained:

- Dust regularly with a soft cloth.

- Avoid strong chemical cleaners.

- Protect from direct sunlight to reduce fading.

- Refresh finishes with oil or polyurethane every few years.

Sustainability and Environmental Impact of Walnut Plywood

One question I often hear is whether walnut plywood is an environmentally responsible choice. The good news is that plywood construction is generally more sustainable than using solid hardwood boards. Because walnut plywood uses a thin veneer over a layered core, manufacturers can produce more surface material with far less walnut lumber. This reduces waste and allows valuable walnut logs to go much further.

Another plus is that many suppliers now follow FSC (Forest Stewardship Council) standards, which means the wood is sourced from responsibly managed forests. If sustainability matters to you, it’s worth asking your supplier about certification before buying.

Of course, not all walnut plywood is equal. Imported panels may vary in quality and in how the veneer is sourced. Domestic walnut plywood often costs a bit more, but it typically comes with clearer supply-chain transparency.

For builders who want a balance between beauty and responsibility, walnut plywood offers a practical way to enjoy hardwood aesthetics while keeping material use efficient.

Final Thoughts

Every time I work with walnut plywood, somebody comments on it. Friends and family will stop and ask, “What wood is that?” because the dark color and grain are hard to mistake. It has a way of making even a simple weekend build look like it came from a custom shop.

It does run higher in price than birch or oak, and you have to watch out when sanding so you don’t cut through the thin veneer. Still, I’ve never regretted using it. For me, walnut plywood strikes the right balance—good looks, solid strength, and enough practicality to justify the extra cost.