I didn’t expect the stairs to be the thing that annoyed me most about my house. But every time I walked up them, I saw that awful old carpet, fraying at the edges, looking dirty even after vacuuming. So one day, without much of a plan, I grabbed a utility knife and started ripping it up.

Turns out the wood underneath wasn’t real wood at all—just plywood treads and OSB risers. It was rough. And honestly, it made me want to staple the carpet back on and pretend I never touched it.

But I’m glad I didn’t. That stair makeover turned out to be one of the most satisfying DIYs I’ve done—and I learned a few things that might help you if you’re thinking about doing the same.

The Hidden Reality Under the Carpet

If your home was built in the last few decades, there’s a good chance your stairs are built the same way mine were: plywood steps, OSB risers, and a whole lot of glue. Contractors save money using these materials, especially in homes that were originally carpeted top to bottom. They’re not meant to be seen—just covered.

The good news? You can still work with them. Whether you paint, cover, or replace them, there are a few ways to turn those ugly stairs into something that actually looks finished.

Painting Plywood Stairs (When You Just Want It Done)

This was the first option I considered, mostly because I already had some leftover paint and wasn’t ready to spend a lot.

I filled the deep gouges with wood filler, gave it a quick sanding, and painted the treads a deep charcoal color. The risers got a coat of bright white. It wasn’t perfect, but it looked clean. And for about $40 in materials, I was okay with that.

If you try this:

- Don’t skip the prep. Sand and fill any old staples or glue.

- Use something more durable than wall paint. I used porch & floor paint and it held up surprisingly well.

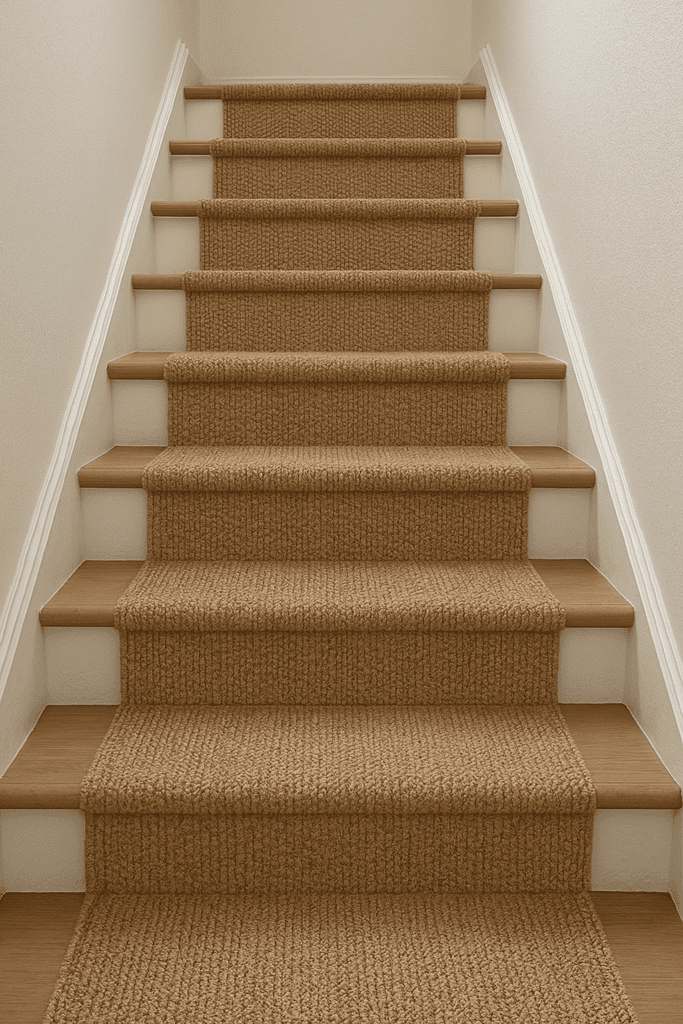

Carpet Runners: A Simple but Cozy Fix

If you want something softer underfoot (especially for kids or pets), a runner might be the way to go. After a few months of painted stairs, I added a runner to cut down on noise and protect the paint.

The install was easy:

- Tack strips at the top and bottom

- Staple gun for the risers and behind the bullnose

- A cheap stair tool to tuck everything tight

It gave the stairs a more finished look and made them way safer.

When You Want That Real Wood Look (But Not the Cost)

Eventually, I wanted something that felt more permanent. I looked into full hardwood treads, which cost around $90 a piece. Multiply that by 12 or 13 steps, and you’re close to $1,200 before stain or finish.

Instead, I found a hardwood overlay kit. These are pre-made stair caps—real wood on top, with a bullnose edge—that you glue right onto your existing treads.

The install took a weekend. I used Loctite construction adhesive, clamped each tread for a few hours, and added wood filler along the seams.

They’ve held up great so far. Honestly, they look like solid hardwood unless you’re inspecting up close.

Not into Wood? Laminate Still Works for Stairs Makeover

If you’ve got laminate floors in the rest of your house, you can carry that look up the stairs too. Just know that the regular click-and-lock method doesn’t work here. You’ll need to glue each piece down with something like Roberts adhesive.

Laminate treads don’t feel as solid underfoot, but they’re affordable, and you can match your floor for a seamless look.

Don’t Forget the Details: Rugs, Nosing, or Even Just a Deep Clean

One of the easiest upgrades? A set of non-slip tread rugs. I added these over the painted stairs before I installed wood overlays, and they worked great for traction and looks.

Another option: just replace the bullnose if that’s the part that’s damaged. You’d be surprised how much cleaner stairs look when the edge is fixed.

Final Thoughts from a Tired but Happy DIYer

I didn’t set out to give my stairs a makeover. But now that it’s done, I honestly wish I had tackled it sooner. The house feels more “finished” and it cost a fraction of what I thought it would.

If you’re thinking about starting, just know there’s no perfect way—just the best way for your time, budget, and patience.

Quick Resource List

| Item | Link |

|---|---|

| Epoxy/porch paint | Amazon |

| Carpet runner | Amazon |

| Hardwood overlay kit | Amazon |

| Laminate tread kit | Amazon |

| Stair tread rugs | Amazon |

Here’s your downloadable PDF file of the stairs makeover guide: