The heavier the plywood, the stronger the support structure needs to be. While most projects can handle the weight, overlooking this factor, especially when carrying sheets up ladders or scaffolding, can pose serious safety risks. Always double-check that your framework can hold the weight of the plywood you’re using.

🪚 Planning Projects with Plywood Weight in Mind

Understanding plywood weight isn’t just about physical handling—it directly affects project design, transportation, fastener choice, and structural integrity. For example, if you’re building cabinets, heavy hardwood plywood may cause drawer slides to sag over time unless you choose industrial-rated hardware.

If your plywood will be wall-mounted, like in shop storage or decorative paneling, you’ll need to ensure your wall anchors or studs can carry the load. Even shelving depth should be re-evaluated based on the weight of the plywood alone, let alone the items being stored. On job sites, you’ll also need to account for how many sheets can be carried safely by one person or transported in a vehicle without exceeding payload limits. DIYers working in small shops or home garages might benefit from breaking down sheets with a track saw or circular saw outside, then bringing smaller pieces inside. This avoids dangerous overhead lifting or narrow-door maneuvering with full 4×8 sheets. On a finer level, even sanding techniques and stain absorption can be influenced by plywood weight, because denser, heavier sheets often have tighter grains or more resin in the surface plies, which resist stain penetration.

Choosing the right weight—and matching it with the right tools, supports, and finishing methods—can be the difference between a warped disaster and a professional result. Don’t just grab any plywood off the rack—match the weight to the application. That’s how pros build smarter and safer.

Why Is Plywood So Heavy? (Plywood Weight Explained)

Plywood tends to weigh more than solid wood, primarily due to two factors:

- Core Veneers: The type of wood used in the core layers can be denser than solid wood.

- Rosin Adhesive: These glues add more weight than the wood itself.

This combination often makes plywood denser than some hardwoods. Manufacturing methods also vary by mill, so even similar-looking plywood sheets can weigh significantly differently.

Resin vs. Wood Fiber in Plywood Construction

The more resin in a sheet, the heavier it gets. But resin doesn’t add strength—wood fibers do. That’s why a heavier sheet doesn’t necessarily mean a stronger one. In fact, more resin and less fiber can actually weaken it.

Handling Heavy Plywood Sheets (Up to 80 Pounds!)

A standard 4×8 sheet of plywood can weigh over 80 pounds. That’s not just heavy—it’s dangerous to handle solo. Lift improperly, and you’re risking a serious back injury.

Plywood Weight Charts and Thickness Comparisons

Softwood Plywood

Softwood plywood is one of the most commonly used types. According to the APA, it weighs around 3 pounds per square foot per inch of thickness. Remember that sanding reduces a bit of thickness—and, therefore, weight.

| Plywood Type | Weight (lbs, 4’x8’x1/2″) |

|---|---|

| Softwood | 40 |

| Hardwood (Birch Core) | 65 |

| Hardwood (Poplar Core) | 52 |

| OSB | 56 |

| MDF (Light) | 60 |

| MDF (Heavy) | 75 |

| HDF | 82 |

Comparing Other Plywood Types

For comparison, here’s how 1/2″ thick plywood types stack up against softwood plywood.

Plywood Weight Comparison (4'x8'x1/2")

Softwood: 40 lbs

Hardwood (Birch Core): 65 lbs

Hardwood (Poplar Core):52 lbs

OSB: 56 lbs

MDF (Light): 60 lbs

MDF (Heavy): 75 lbs

HDF: 82 lbsHeavier plywood often means a higher price tag. That’s why weight charts also give you insight into cost.

Full Range of Plywood Weights

Using this reference, here’s a full list of plywood types and thicknesses in order of weight. Softwood is the benchmark.

| Plywood Type | Thickness (inches) | Weight (lbs) |

| Softwood | 1/4 | 20 |

| Softwood | 1/2 | 40 |

| Softwood | 3/4 | 60 |

| Hardwood (Poplar Core) | 1/2 | 52 |

| Hardwood (Birch Core) | 1/2 | 65 |

| OSB | 1/2 | 56 |

| MDF (Light) | 1/2 | 60 |

| MDF (Heavy) | 1/2 | 75 |

| HDF | 1/2 | 82 |

Hardwood Plywood Variation

Hardwood plywood weight varies wildly based on the core material. For example:

- Birch core: 650–700 kg/m³

- Poplar core: 500–530 kg/m³

[Note: This doesn’t include HDF/hardboard due to thinner sheet sizing.]

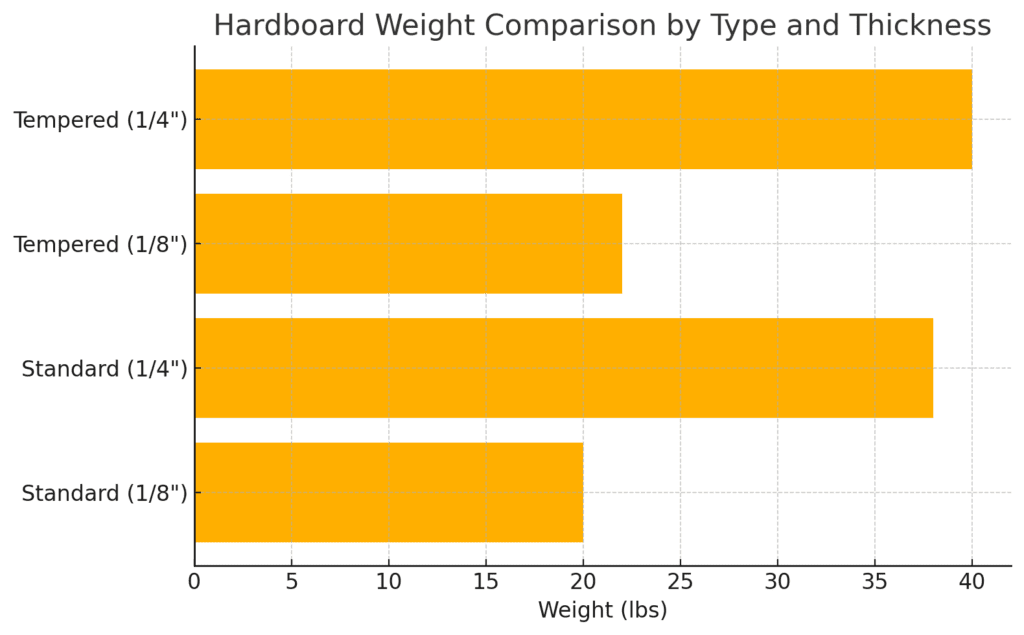

Hardboard Weight Reference

Below is a comparison chart of hardboard weights based on type and thickness:

| Hardboard Type | Thickness (inches) | Weight (lbs) |

| Standard Hardboard | 1/8 | 20 |

| Standard Hardboard | 1/4 | 38 |

| Tempered Hardboard | 1/8 | 22 |

| Tempered Hardboard | 1/4 | 40 |

Plywood Weight Calculator

Use the calculator on our site to find weight in pounds or kilograms. Input the wood type, thickness, width, and length. Keep in mind, moisture can throw off accuracy by as much as 20%.

Does Plywood Weight Equal Strength?

A common myth: heavier plywood = stronger plywood. Not true. Since adhesives make up the added weight and not wood fiber, strength actually comes from:

- Type of plywood

- Sheet thickness

- Proper structural support

Smart Shelf Support Tip

Want more substantial plywood shelving? Add a 1×2 or 1×4 to the front edge, mounted at 90 degrees. Even better, reinforce both the front and back. This trick shifts stress points and significantly reduces sagging.

How to Handle and Cut Heavy Plywood Safely

1. Rough Cut First

Cut your sheets slightly oversized first. If breakage happens, it won’t ruin your finished piece. Then, make a clean final cut.

2. Let the Pros Cut It

Big box stores and lumber yards usually offer free or low-cost cuts. Use them for large pieces, then finish the more minor cuts in your own shop.

3. Use Wheeled Shop Carts

Don’t risk your back. Build a couple of shop carts the same height as your saw. Locking casters give you flexibility and safety.

4. Add a J-Hook Lifter

Build a J-Hook lifter with hinges to make loading plywood onto your cart a breeze. It centers the plywood perfectly while saving your spine.

5. Clamp With a Right-Angle Jig

Joining plywood at 90 degrees? Use a homemade jig and ratcheting clamps. This makes the job easy and keeps your project square.

FAQ: Common Questions About Plywood Weight

How heavy is a 3/4-inch sheet of plywood?

A standard 4’x8′ softwood plywood sheet 3/4 inch thick weighs around 60 pounds. The weight can vary depending on the wood type and moisture content.

What’s the lightest type of plywood?

Typically, softwood plywood is the lightest. A 1/4-inch thick sheet can weigh as little as 20 pounds.

Does heavier plywood mean it’s stronger?

Not always. Weight usually comes from resin and adhesive, not wood fiber. Strength depends more on wood content, thickness, and support.

How much does a 1/2-inch MDF or HDF sheet weigh?

- MDF (Light): ~60 lbs

- MDF (Heavy): ~75 lbs

- HDF: ~82 lbs

Why does plywood’s weight vary by manufacturer?

Different mills use different resins, glues, and wood species. This causes noticeable weight variation even among same-size sheets.

With the right prep, tools, and know-how, handling heavy plywood becomes a lot safer and your projects a lot sturdier. Whether you’re building shelves, cabinetry, or full furniture pieces, understanding plywood weight and structure gives you the upper hand.

Stay safe—and build smarter.