Joinery is one of the most critical parts of woodworking, especially fine woodworking. Often, the most important difference between an experienced woodworker and a novice is their joinery skills. The ability to make tight joints that enhance a piece’s beauty, rather than detract from it, is a skill that takes time to master.

For beginners, nails and screws are often the joinery method of choice. But as experience grows, these fasteners are replaced by wood glue and more complex joints where the shape and cut of the wood carry the weight, while the glue holds the pieces together.

Wood glue is essential in fine woodworking. While a well-cut mortise and tenon joint can technically hold without glue, that’s uncommon. Creating glue-free joints is a high-level craft reserved for master woodworkers and traditional artisans, like those who restore Japanese temples. For most of us, wood glue is the reliable solution.

Why Wood Glue Is Preferred in Joinery

Glued joints have clear advantages: no nail or screw holes to hide and a cleaner, more seamless finish. The only issue to manage is glue squeeze-out, which can be controlled with proper clamping and cleanup techniques.

But is wood glue strong enough? Surprisingly, yes—it’s stronger than screws or nails. Fasteners only grip at a few points. Glue, on the other hand, bonds the entire surface area of the joint. Properly applied and cured wood glue forms a bond with a tensile strength of 3,600–4,000 PSI, stronger than the wood itself. When stressed, glued joints tend to cause the surrounding wood to break before the glue line does.

Curing vs. Drying: What’s the Difference?

This strength is only achieved once the glue is fully cured, not just dried. Drying happens first, within 30 minutes to an hour, when most moisture evaporates and the glue sets. At this stage, light clamping may be removed on unstressed joints. But for load-bearing or stressed joints, the glue needs at least 24 hours to fully cure.

Curing is when the internal polymers align and the joint gains full strength. In humid or cold conditions, curing can take up to 72 hours. During this time, stress should be avoided to prevent weakening the bond.

Other Adhesives: How They Cure

Adhesives like epoxy and polyurethane glue undergo a more chemical curing process. For example:

- Epoxy doesn’t dry—it cures chemically. Evena 5-minute epoxy should be left 24 hours to fully cure.

- Polyurethane glues (like Gorilla Glue) cure via moisture, which is why the instructions call for lightly wetting one surface.

- Cyanoacrylate (Super Glue) also cures with atmospheric moisture.

Each of these follows the same two-phase process: an initial set that makes the joint immovable, followed by a full-strength cure.

How to Speed Up Wood Glue Curing Time

If you’re on a deadline, you can take steps to help the glue cure faster. While these methods won’t instantly cut the 24-hour cure time in half, they can make the process more efficient:

✅ Use Fresh Glue

Old glue performs poorly. It may separate or thicken over time, slowing the drying process.

✅ Increase Air Flow

Drying is evaporation. Use fans or ventilated areas to help remove moisture faster—just avoid blowing dust onto your project.

✅ Add Gentle Heat

A warm room speeds drying. You can also carefully apply heat with a hair dryer (not a heat gun, which may scorch the wood).

✅ Reduce Humidity

High humidity slows curing. A dehumidifier or air conditioner can help balance moisture levels in your shop.

✅ Apply Thin, Even Coats

Too much glue slows the cure. Apply only what’s needed for coverage. Excess glue increases drying time and can interfere with finishing.

✅ Glue Unfinished Wood

Bare wood allows moisture to escape and be absorbed. Finished wood traps moisture and can slow the cure.

❌ Don’t Dilute the Glue

Watering down glue does not make it dry faster—it just increases the water content, which prolongs curing.

✅ Clamp It Properly

Clamping helps squeeze out excess glue and spreads it evenly. It also keeps joints immobile during the curing phase, improving bond strength.

Alternative Glues for Faster Curing

If you’re working in tough conditions or need faster results, consider switching glues:

🔹 Polyurethane Glues

These cure with moisture and are ideal in humid environments. Mist lightly for faster activation.

🔹 Cyanoacrylate (Super Glue)

Quick setting for small joints. Moisture in the air activates the bond. Optional misting can help.

🔹 Epoxies

Choose your hardener based on the desired working time. Some epoxies allow for full handling in 1 hour. Warming the resin before use speeds up curing.

Testing and Trusting Your Glue Joint

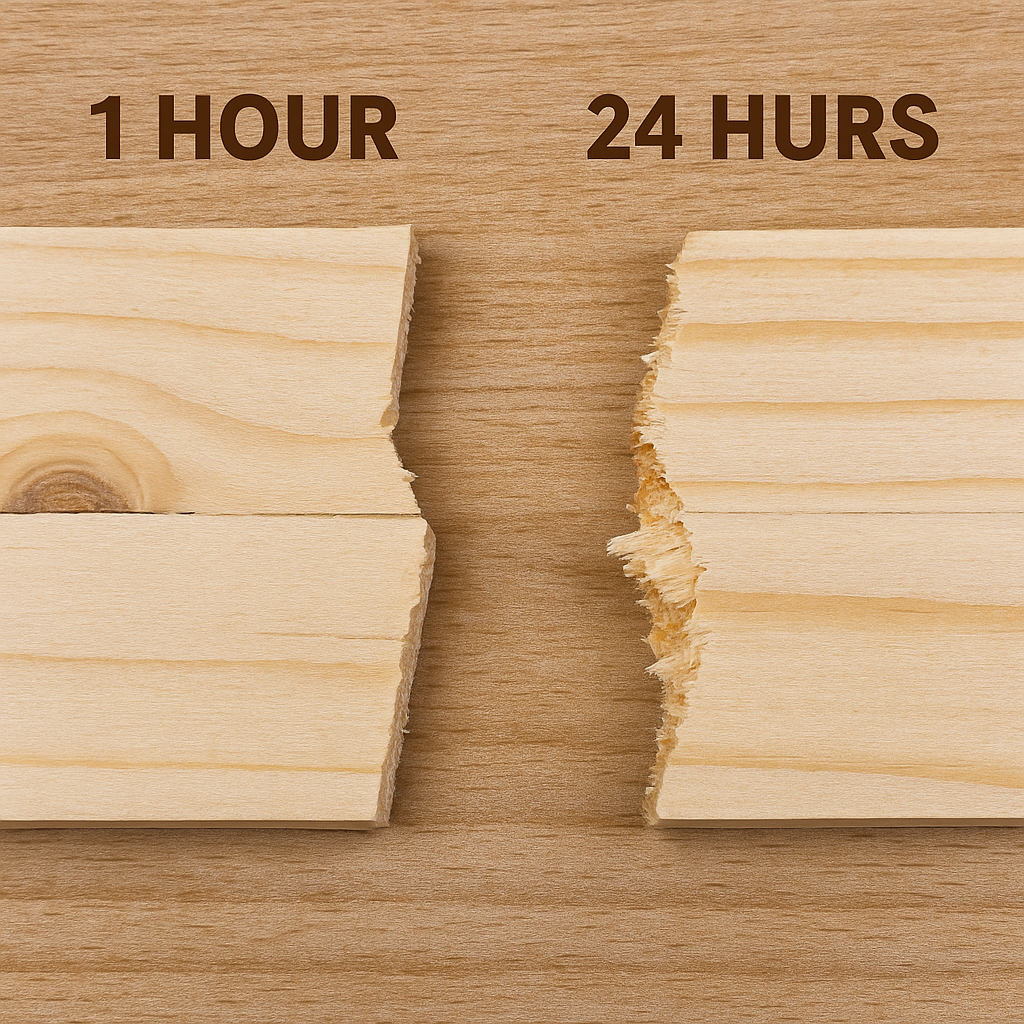

When you rely on wood glue to hold your project together, you want to be sure it’s doing its job. One easy way to build trust in your glue-up is to do a simple test using scrap wood. Glue two small pieces together, clamp them securely, and wait. After just 45 minutes, the joint may seem firm to the touch. But apply some force—and you’ll often find that it comes apart more easily than expected. That’s because the glue is only dry, not fully cured.

Now take that same setup, but this time give it a full 24 hours. When you come back, the result will surprise you. Instead of the glue letting go, the wood fibers around the glue line often tear apart, showing just how strong a cured joint can be. This kind of bond is what you want when you’re making furniture, mounting shelves, or building something meant to last.

The strength of cured glue is especially important in joints that bear weight—like a table leg or a bookshelf bracket. If the glue hasn’t fully cured, those joints can fail when put under load, even if they seem “set.” Patience pays off here. Giving your joints the full recommended cure time, especially under proper clamping pressure, leads to results you can rely on.

For even better results, choose the right glue for your environment. For humid spaces, Titebond III is ideal thanks to its waterproof formula. If you need a fast grab for indoor use, Gorilla Wood Glue is a solid pick.

You’ll see that the glue might hold at first, but only after 24+ hours does the bond truly match the strength of the wood. Done right, a good glue joint will rip the wood fibers apart before the glue line gives out.

Final Thoughts: Glue Curing vs. Drying Time

Understanding the difference between drying and curing helps prevent weak joints and failed builds. Always plan your glue-up schedule around full cure time, not just the initial set. Whether you’re gluing cabinetry, furniture, or workshop fixtures, patience pays off in strength.

When in doubt? Let it cure overnight.

Recommended Reading:

Amazon Picks: