For a proper chair seat replacement, removing the old upholstery, including the worn-out foam padding, is best. You’ll need upholstery fabric, high-density foam, polyester batting, and a staple gun to secure the new material. Choosing the right upholstery fabric is crucial, as stretchable fabrics won’t provide the proper support. A pneumatic staple gun is ideal, but a spring-loaded one will work, too.

How to Remove a Chair Seat for Reupholstery

To remove a chair seat, flip the chair over and unscrew the seat from the frame. If there’s a dust cover, peel it off to access the staples or tacks securing the upholstery. Remove the fabric, batting, and foam padding, scraping off any glued material if needed. Older chairs may have natural padding like horsehair or cotton, which can add value if preserved. You can replace the padding with similar materials or modern foam.

Step-by-Step Guide to Restoring a Wooden Chair Seat

Assess the Damage: Check for cracks or breaks. If the damage is minimal, you can glue it. For larger issues, you’ll need to replace the seat.

Remove the Seat: Carefully unscrew or unbolt the seat from the chair frame.

Choose the Right Material: If you’re replacing, choose sturdy wood like oak, maple, or plywood.

Cut the Replacement Seat: Trace the shape of the old seat onto the new wood, then cut it out.

Finish and Attach: Sand the edges and finish the wood before reattaching it to the frame.

How to Repair or Replace a Chair’s Wooden Seat

- Start by inspecting the seat for damage. If it’s cracked or weak, check if it can be repaired with wood glue and clamps. Remove the seat by unscrewing it from the frame if a replacement is needed. Please choose a suitable replacement material, trace the old seat shape onto the new wood, and cut it out. Sand the edges smoothly, stain or paint as desired, and securely attach it back to the chair.

Fixing a Damaged or Broken Chair Seat

- If the wood has minor cracks, inject wood glue into the cracks and clamp the seat until it dries. Use reinforcing plates or brackets underneath for extra strength for broken or split seats. If the seat is wobbly, tighten or replace screws and nails. Sand rough areas and refinish to match the original look.

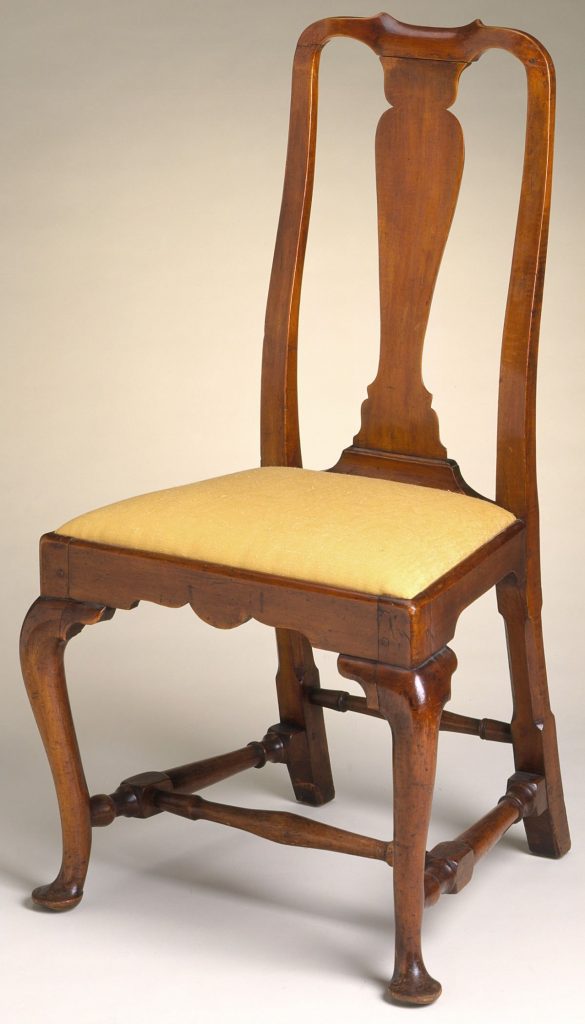

Choosing the Right Wood for Chair Seat Replacement

- Consider durability and comfort when selecting wood. Hardwood options like oak, walnut, or cherry are strong and long-lasting, while plywood is a more affordable and lightweight alternative. Matching the original wood preserves the value of antique chairs. If unsure, check the old seat’s wood grain and thickness before buying new material.

Step-by-Step Guide to Restoring a Wooden Chair Seat

- First, remove the old seat and assess its condition. Clean and sand the surface if restoring, then apply wood filler for dents or scratches. Stain or paint to match the original finish. If replacing, use the old seat as a template to cut a new piece, sand the edges, and attach it securely with screws. Finally, add a protective finish to enhance durability and aesthetics.

Steps to Upholster a Dining Chair Seat

Attach the Foam:

Cut high-density foam to fit the wooden seat exactly. Spray the seat with adhesive and press the foam in place, ensuring it’s secure. If you want a rounded edge, spray adhesive on the foam’s edge and fold it over to cover the top of the seat.

Add Batting:

Cut polyester batting 3 inches larger than the seat. Staple it to the seat, starting from the center and working outward. Stretch it tightly to avoid wrinkles.

Install Upholstery Fabric:

Cut upholstery fabric 4 inches larger than the seat. Mark the centerlines and align the fabric with them. Staple the fabric, working from the center out, and ensure it remains straight.

Handle Corners Carefully:

Neatly fold the fabric at the corners to avoid lumps. Be sure the folds align straight to keep a clean appearance.

Trim Excess Fabric:

Rem trim the excess once the fabric is stapled, leaving about 1 inch from the staples.

Add a Dust Cover:

Cut cambric fabric to size and staple it to the bottom of the seat. Start from the center and work your way out, securing the fabric tightly. This step gives the bottom a clean finish.

Reassemble the Chair

After completing the reupholstery, reattach the seat to the chair frame. Use the same screws or fasteners that were originally used, ensuring alignment with the previous positioning. Avoid using power tools like drills to prevent damaging the fabric. Double-check the screws and tighten any loose ones to secure the chair’s structure. If a dust cover was not added during upholstery, install it on the bottom edge of the chair skirt, keeping it discreet from view.

Here’s a list of essential tools and supplies you can order on Amazon for reupholstering a chair, all recommended by experts:

- Staple Gun – A heavy-duty or pneumatic stapler like the Arrow T50 will help attach the fabric.

- Foam Sheets – High-density foam (1” thick) for seat padding.

- Upholstery Fabric – Durable fabric suitable for furniture.

- Dacron Batting – Polyester batting for padding under fabric.

- Spray Adhesive – A strong adhesive for foam.

- Upholstery Scissors – Sharp scissors for cutting fabric and foam.