Smoked meat is a favorite of many people. There’s just something about the smoke flavoring that tickles the taste buds, making the meal more enjoyable. But that’s not where smoking began. The act of smoking meat probably goes back to the days when people lived in caves and is one of the oldest means of food preservation that exists.

Much of the meat smoked today is only “cold smoked” to give it the distinctive smoke flavoring. But using smoking as a means of preserving meat requires “hot smoking,” allowing the smoke to raise the temperature inside the smoke hot enough to slow cook it. This not only infuses the smoke flavor into the meat, but it also tenderizes it, as pretty much any slow cooking method will do.

Smoking preserves through a combination of factors. First, the meat is soaked in a brine, infusing salt into the surface. Salt is a natural preservative, because it draws moist out of cells in a process called “osmosis.” Not only does it draw moisture out of the cells in the meat, but also in any bacteria that is contained in that meat, killing the bacteria. The low moisture content of the surface layer of the meat is then an inhospitable environment for new bacteria to invade.

Taking that a step further, the process of hot smoking causes the collagen in the outer part of the meat to be chemically converted, turning it into an impermeable “skin” called pellicle, which both helps to keep moist in and keep bacteria out. But there’s a potential problem with that, because when the meat is cut, the cut surface doesn’t have the pellicle. So it either needs to be smoked again or used fairly quickly before bacteria can get into the meat.

Many people buy smokers or barbecue grilles which have a smoker built in. This typically allows for the smoking of something the size of a large turkey, perhaps with a couple of strings of sausage on the side. But what does one do, when they regularly smoke more meat than that? They need a smokehouse.

Smokehouses were a common fixture around farmhouses and ranches throughout the 1700s and 1800s. Refrigeration was rare in those times, limited to ice boxes; and the ice box was only useful if one lived close enough to an ice house to be on their delivery route. Those who lived in the country couldn’t count on that, so they built smokehouses to preserve the meat from the animals they slaughtered. These were often rather crude affairs, as the main purpose of the smokehouse was to keep the smoke in and predators who might want to steal the meat out. Nevertheless, there were certain design requirements that had to be included, for the smokehouse to be able to do its job.

One of the most unique 19th century smokehouses I’ve ever seen wasn’t really a smokehouse. Rather, the chimney of the house was built large enough that several entire sides of meat could be hung in it, smoking them. Not only was this extremely convenient for the family who owned that house, but hanging the meat back in the chimney after cutting a section off allowed the meat to form a new pellicle, preserving it longer.

Keys to Effective Smoking

There are several basic keys to effective smoking, although the process itself really isn’t all that complicated. The first is the ability to control the temperature in the smokehouse. This is where smoking is clearly different from barbecuing. In barbecuing the meat is directly over the fire, so that it receives the most possible heat. But in smoking, a lower temperature is used, so the fire must be off to one side, with the smoke piped into the smoker or smokehouse.

The second key thing is to add moist to the smoke, so that it is a combination of smoke and steam. That will help keep the meat from drying out during the smoking process. While it is possible to smoke some meats without adding steam to the process, the meat may tend to get rather dry.

Then there’s a need to hang the meat or put it on a grate. The idea is to have as much of the meat exposed to the smoke as possible, so that the smoke can do its magic to the meat. If the meat were to sit on a shelf, rather than being hung or on a grate, then the part of the meat that was in contact with the shelf wouldn’t be touched by the smoke. Besides that, the shelf would block flow of the smoke through the smoker.

Finally, the entire process has to be monitored. For most hot smoking, that means monitoring it for 24 hours or so, which is the biggest turn-off for most people when it comes to smoking. But for those who invest that time, the results are worth it.

Building a Basic Smokehouse

A smokehouse doesn’t have to be complicated to be effective. In fact, anything that would work as a storage cabinet or small garden shed will work. Don’t go too big, as it then becomes hard to heat the smokehouse up and fill it with smoke. As an outside limit, I wouldn’t go any bigger than four foot square for most purposes, although I’ve seen them as large as eight foot square. Even so, those larger smokehouses don’t necessarily allow for smoking more meat at one time, as it is necessary to leave room to go inside and move around in them. Smaller ones don’t need that.

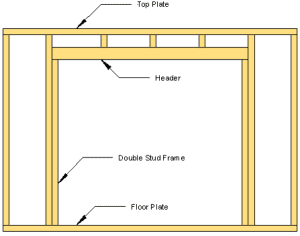

The walls and roof of the smokehouse are made of a single layer of material, attached over a framework. There really is no reason for more than this, as anything done to make the inside look nicer will simply be covered by smoke. Even so, it is important that the exterior be well sealed, preferably by the way the wood is joined together, rather than by the use of caulking or other sealers that may shrink due to the heat.

The smokehouse cabinet can be made out of any type of wood, including softwood plywood. Nevertheless, cedar is one of the more popular woods to build a smokehouse out of, because the natural oils contained in cedar repel wood-destroying fungi that cause rot. This is the same reason why cedar is used for fences; but if fence material is used (it can be) the edges need to be jointed, so that they fit tightly together, unlike on a fence, where small gaps are permitted. Another wood that can be used is redwood, which is also resistant to insects and rot. Finally, many people build their smokehouses out of pine, for its low cost.

Regardless of the type of wood used, it’s a good idea to cut the edges, tongue and groove on a router table, so as to help eliminate gaps that the smoke can leak out from. Additionally, corner and the door frame should be lap jointed, eliminating gaps there as well. Keep in mind that the smokehouse will be exposed both to the elements and to heat, so the boards will tend to expand and contract somewhat. So, even though the joinery needs to overlap, there needs to be gaps as well, not where air can go through, but rather where the wood pieces can slide across each other, allowing for expansion and contraction. Avoid using any sort of rubber seals, as the heat will affect them.

Build the smokehouse walls to accommodate a shed type roof, with the front side higher than the back and both side walls angled. For the roof itself, normal construction methods can be used, setting joists across the span between the front and back walls, with plywood sheathing over that, covered by normal asphalt shingles. Just make sure that the gaps between the joists are filled, so that airflow can be controlled.

Sealing the roof isn’t to say that there shouldn’t be any airflow through the smoker. Rather, a vent should be installed near the peak of the roof, above the doors. This needs to be covered by some sort of screening or perhaps poultry cloth on the inside, to keep animals from getting into the smokehouse. It also needs a sliding cover over the outside, allowing the amount of open vent to be adjusted, as a means of controlling the internal temperature.

A single door or double doors can be installed in the front side of the smokehouse. Care should be taken in their construction to ensure that they are stabilized against warping and the door’s themselves or the frame should be made in such a way as to cause some overlap, keeping the smokehouse sealed.

Drill a hole somewhere in the doors or walls of the smokehouse, about head height and install a dial thermometer through the hole. It will be important to be able to check the internal temperature while smoking the meat, without having to open the doors and let the heat escape.

Inside the smokehouse there’s a need for a combination of grated shelves and bars to hang the meat from. I would recommend installing cleats on both sidewalls, allowing the bars and grates to be set where needed for that smoking session. As most people tend to smoke a variety of different types of meat in their smokers, having the ability to change how the smokehouse is configured between uses can be very helpful.

The only other thing that is needed is a firebox to produce the hot smoke that will go into the smokehouse. One option for this is a camp type wood burning stove. These are generally fairly simple, inexpensive and close to the ground. Another option is to build a fire box out of brick. In that case, it is important to build the firebox low to the ground and sealed, so that the smoke can go directly into the lower part of the smokehouse. Keep either of these a couple of feet from the smokehouse itself and run a piece of chimney pipe from the fire box into a hole in the lower part of the back wall of the smokehouse.

Using the Smokehouse

Proper smoking of meat is actually a three-stage process, at least if the smoking is intended to produce meat that is preserved. If all that’s wanted is smoke flavoring, then all that’s needed is the cold smoking part of the process.

Smoking isn’t usually done alone, but is done in conjunction with either curing or dehydrating. Curing adds salt to the meat, which as I mentioned earlier creates an inhospitable environment for bacteria. Dehydrating also creates an inhospitable environment, but through a different means. It is not unusual to use a combination of the two, adding salt to the meat and then dehydrating it. Dehydration can be done right in the smokehouse by simply leaving the meat in it longer.

Curing

Before proceeding it is necessary to decide whether a wet cure or dry cure is to be done. For a wet cure, a brine of at least 20% salt, dissolved in water, needs to be made. In order to do this, it may be necessary to heat the water to boiling, in order to get that much salt to dissolve in it, and then allow it to cool to room temperature before submerging the meat. Ensure that the meat is fully submerged, weighing it down if necessary and allow it to soak for at least 24 hours.

Dry smoking is done with a meat rub, rather than with brine. The advantage of this is that meat rubs allow for additional spices to be added, further flavoring the meat. When using them, physically rub the meat rub into the surface of the meat, ensuring that it covers the entire surface with a nice thick coating. Take special care to rub the meat rub into joints, as those can be tricky. If a meat rub is used, then the meats should sit for at least 12 hours before smoking.

Any sausage that is to be smoked will automatically be being cured, as the sausage recipe will require the addition of curing salt to the mixture, before stuffing it into the casing. Curing salt differs from other salt in that it has nitrates and nitrites added in precise amounts, to ensure the curing process.

Cold Smoking

Cold smoking is the part of the process where the smoke flavor is added to the meat. This is normally done at 68 to 86°F (20 to 30°C). This part of the process usually lasts one to one and a half hours per pound of meat in the largest chunk being smoked. This time can vary, depending on the type of meat being smoked. In order to be sure of what the right amount of time is, check recipes for smoking the meats that are in the smokehouse. An excellent tool for this exists at this site.

Hot Smoking

Once cold smoking is completed, hot smoking begins immediately. In this stage, the temperature is raised up to 200 to 225°F, a fairly low temperature for cooking meats. However, the idea here is to slowly cook the meat, not to cook it rapidly. Slow cooking helps to break down the natural toughness of the meat, turning even the toughest cuts tender.

The weight of the meat and the type will affect how long the meat must be hot smoked, before it is done. Times can be found in the same recipes which are used for checking the cold smoking times. Regardless of what the recipes say, always check the internal temperature of the meat, as that is the true indicator of when it is done. Proper internal temperatures can be found at FoodSafety.

There may be times when it is desirable to overcook meat, such as when making pulled pork. Both brisket and pork will tend to fall apart when cooked to 200°F, which is ideal for pulled pork. Leaving the meat longer can also cause dehydration of the meat, which is desirable in some situations.