Board and batten is a wall and siding style that uses wide vertical boards as the base surface and narrow strips called battens to cover the seams between them. Originally developed as exterior barn siding, board and batten is now commonly used for interior feature walls and modern farmhouse exteriors.

When you look around at renovation photos these days—Instagram, Pinterest, even those random DIY videos that pop up at midnight—it’s almost impossible not to notice board and batten. It keeps showing up in all sorts of places: farmhouse living rooms, new-build neighborhoods, even tiny powder rooms where people are trying to make something out of nothing.

What’s funny is that the style looks complicated at first glance, but once you actually try it, you realize it’s pretty straightforward—no fancy joinery, no master-carpenter skills. If you can measure without losing your pencil and keep a level reasonably straight, you’re already halfway there.

My first attempt wasn’t part of some big plan. I had this hallway that drove me nuts—it was long, blank, and somehow managed to feel both narrow and empty at the same time. I tried hanging art, shelves, and paint colors… nothing helped. One Saturday, I bought a stack of boards just to see what would happen. I figured, worst case, I’d rip them down and pretend it never happened. But once the battens were up and I applied a coat of semi-gloss paint, the wall suddenly took shape. Depth. It felt like the house had grown up a little. It was one of those projects where you step back, squint a little, and think, “Wait… did I actually do that?”

This guide comes out of that kind of trial-and-error—the practical stuff nobody tells you upfront. It covers what board-and-batten actually means (it’s simpler than the name suggests), where it makes the most difference, the tools I reach for because they don’t fail me, and the mistakes I’ve made so you don’t have to repeat them. Whether you’re upgrading one sad wall or planning a whole exterior makeover, I’ll walk you through the parts that matter so you can skip the frustration I went through the first couple of times.

What Is Board and Batten?

Board-and-batten is a wall style in which wide boards form the main surface, and narrow vertical strips—battens—run along the top to hide the seams. It started as a practical exterior siding for barns and old farm buildings because the battens helped block wind, rain, and other elements that slipped through the gaps in the boards.

These days, you’ll find board and batten almost anywhere:

- Interior feature walls

- Entire rooms wrapped in trim

- Exterior siding makeovers

- Stairways, mudrooms, and entry halls

- Bedrooms, especially kids’ rooms or primary suites

People love it for two big reasons: it adds instant, built-in character, and it’s surprisingly affordable and simple to install.

If you want to explore similar wall treatments, check out the guides on Plywood Wall Paneling and Shiplap Walls on the site.

Materials for Board and Batten

There’s no single rule for what type of boards you must use. It depends on location, moisture exposure, and the look you’re going for. Here are the most common choices:

For Interiors

- MDF boards or trim pieces — Smooth, affordable, and easy to paint

- Pine boards — Great for a natural wood look or staining

- Plywood strips — You can rip ¼” or ½” plywood into batten widths for a more economical approach

- PVC trim — Perfect in bathrooms, basements, or humid climates

For Exteriors

- Cedar — Naturally rot-resistant

- Engineered wood siding panels — Stable and easy to install

- Fiber cement trim — Durable and low-maintenance

Recommended Tools

Here are dependable tools that make installation easier (Amazon affiliate-ready):

- Dewalt 18-Gauge Brad Nailer – Great for attaching battens cleanly

- Kreg Stud Finder – Helps you anchor into studs when needed

- Irwin Miter Saw – Accurate cuts for battens and trim

- Gorilla Construction Adhesive – Strong bonding for long battens

- Dap Alex Flex Spackling & Caulk – Smooth seams for a flawless finish

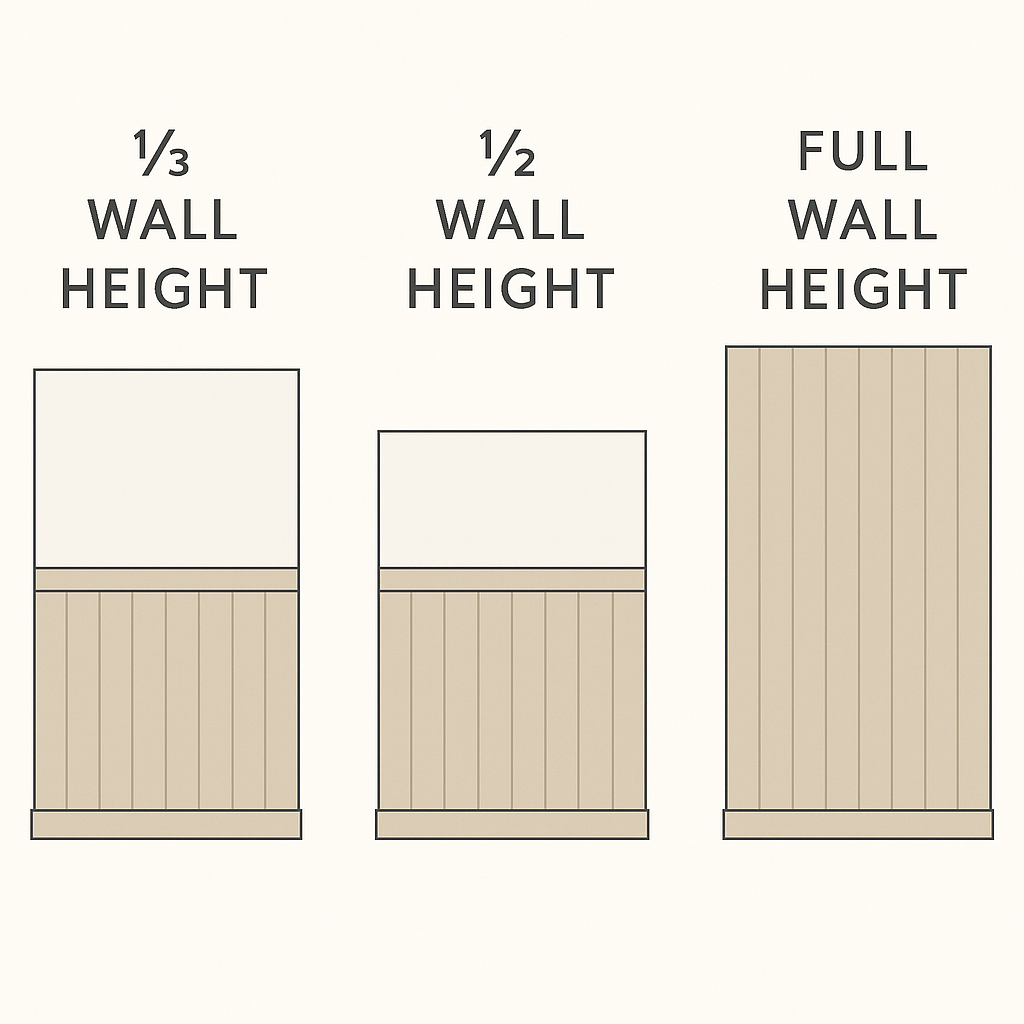

How Tall Should Board and Batten Be?

This is one of the most common questions. While there’s no “correct” height, here are typical dimensions:

- ⅓ of the wall height (classic wainscoting look)

- Half-height (balanced and popular in hallways)

- Full wall height (modern, dramatic, and visually stretches the ceiling)

A standard rule I’ve learned after installing dozens of these:

Go taller in large rooms and shorter in narrow hallways.

It maintains proportions that are comfortable to the eye.

Planning Your Layout (The Step Everyone Rushes—but Shouldn’t)

Before you cut a single board, sketch the wall and calculate spacing. Even spacing is what makes the board and batten look professionally installed.

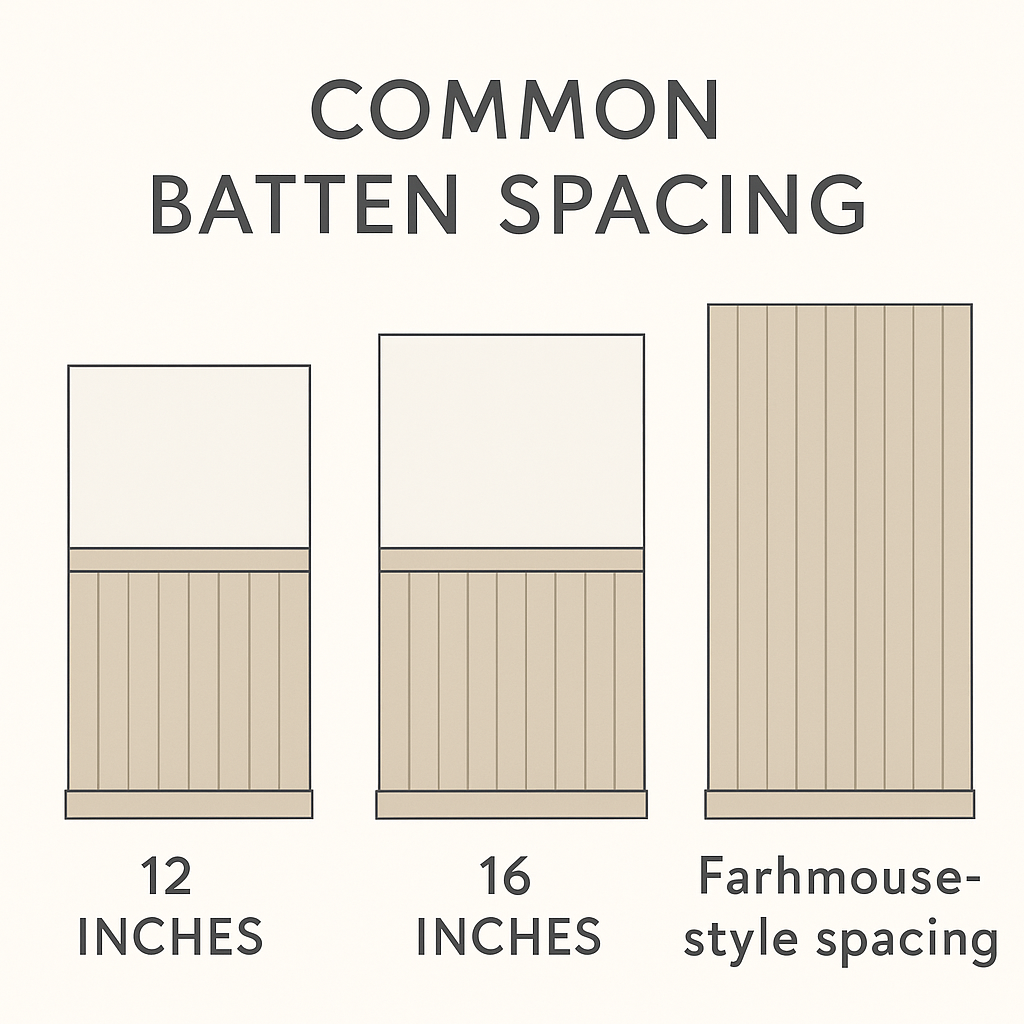

Common Batten Spacing

- 12 inches (tight, modern look)

- 16 inches (works well with stud spacing)

- 18–24 inches (traditional farmhouse style)

Pro Layout Tips

- Always measure the actual width of your battens, not the listed dimension.

- For full-height designs, check corners for plumb—walls are rarely perfectly straight.

- If an outlet or vent is in the way, decide whether to center the batten or shift the spacing slightly.

If you’re installing over plywood subwalls, see:

Best Plywood for Walls.

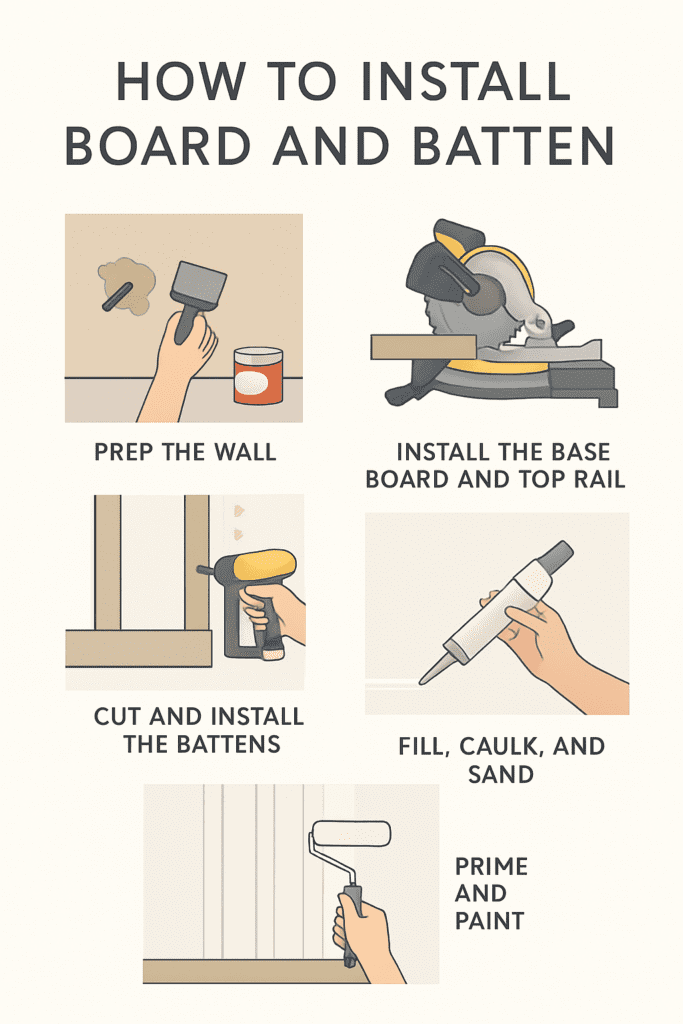

Step-by-Step Guide: How to Install Board and Batten

Below is a straightforward, beginner-friendly installation process based on what I’ve learned through trial and error and, eventually, getting it right every time.

Step 1: Prep the Wall

Even though the battens add texture, you want the base wall to be smooth.

- Remove old baseboards if necessary

- Patch holes and sand lightly

- Clean the dust so the adhesive bonds well

If your wall texture is very heavy, add a sheet of ¼” plywood as a backing layer. (See Plywood Types & Uses.)

Step 2: Install the Baseboards and Top Rail

Most board-and-batten installations include:

- A baseboard

- A top horizontal board or rail

- Vertical battens in between

Make sure your baseboard and top board are level. This determines the entire visual line.

Step 3: Cut and Install the Vertical Battens

- Measure each section individually — walls vary in height

- Add construction adhesive on the back

- Attach using brad nails (18-gauge is perfect)

Pro Tip:

Press the batten into place first, then nail it. If you nail too quickly, you may shift it off level.

Step 4: Fill, Caulk, and Sand

A flawless paint job comes from the finishing steps:

- Fill nail holes with flexible spackling

- Caulk edges where battens meet the wall

- Sand lightly until everything feels smooth under your fingertips

This is where MDF shines — it finishes far cleaner than pine.

Step 5: Prime and Paint

Use a high-quality primer, especially on MDF, which soaks up paint.

For color, white is classic, but dramatic hues such as charcoal, navy, sage green, and even matte black have become increasingly popular.

Paint sheen matters too:

- Semi-gloss for a more traditional look

- Satin for a softer, modern finish

- Eggshell for exteriors

How Much Does Board and Batten Cost?

The cost of board and batten depends on material type, wall size, and whether the project is interior or exterior.

Interior Board and Batten (12-Foot Wall)

| Material Type | Estimated DIY Cost | Durability | Best For |

|---|---|---|---|

| MDF | $150–$250 | Moderate | Painted accent walls |

| Pine | $180–$300 | Good | Stained interiors |

| Plywood Battens | $120–$220 | Good | Budget projects |

| PVC Trim | $200–$350 | Excellent | Bathrooms & basements |

Exterior Board and Batten (Per 100 sq ft)

| Material Type | Estimated Cost | Lifespan | Maintenance Level |

|---|---|---|---|

| Cedar | $400–$800 | 20–30 years | Moderate |

| Engineered Wood | $350–$700 | 20–25 years | Low |

| Fiber Cement | $500–$900 | 30+ years | Very Low |

| T1-11 Panels | $300–$600 | 15–25 years | Moderate |

👉 If you’re comparing exterior options, see the full T1-11 siding guide for a detailed breakdown.

Typical Total DIY Interior Project:

$150–$300

Professional Installation:

$800–$2,000+

Where to Use Board and Batten

Interior Applications

- Living room feature wall

- Nursery or kids’ room

- Hallways that feel too plain

- Staircase walls

- Dining room wainscoting

- Bathrooms (PVC battens recommended)

Exterior Applications

- Porch walls

- Entire home siding

- Detached garages or sheds

- Garden structures

If you’re working with outdoor structures, this article complements it well:

Best Wood for Outdoor Projects.

Choosing the Right Wood (Strength, Durability & Cost)

Interior MDF

Advantages: smooth, affordable, easy to paint

Downside: not moisture-friendly

Interior Pine

Advantages: real wood, natural grain

Downside: knots can bleed unless primed with shellac

Exterior Cedar

Advantages: resists rot, insects, and moisture

Downside: more expensive but long-lasting

Plywood Battens

Advantages: most affordable for large projects

Downside: edges must be sanded and sealed carefully

Learn more about plywood options in:

Plywood Grades Explained.

Common Mistakes to Avoid

1. Poor Spacing

Uneven spacing is the #1 giveaway of a rushed DIY job. Always measure from the center line of each batten outward.

2. Skipping Primer

MDF mainly soaks up paint and shows seams without primer.

3. Using Battens That Are Too Thin

Batten thickness should feel substantial. I recommend ¾” thickness or ½” minimum for interior walls.

4. Not Checking Wall Straightness

Old homes have walls that bow. If you attach a rigid board to a bowed wall, you’ll see gaps.

5. Forgetting to Paint the Edges

Raw wood edges absorb paint and look dull next to the finished surface.

How Much Does Board and Batten Cost?

Costs vary by materials and whether you’re doing a full room or a single accent wall.

Approximate DIY interior pricing:

- MDF battens: $60–$200, depending on the wall

- Pine battens: $100–$250

- Primer and paint: $40–$80

- Construction adhesive: $5–$10

- Caulk and filler: $6–$12

For a typical 12-foot wall, most DIYers spend $150–$300 all-in.

Compare that to what contractors charge—$800 to $2,000+—and the savings become obvious.

Should You DIY or Hire a Pro?

DIY is best if:

- You have basic tool experience

- You enjoy detail-oriented projects

- You’re installing an interior accent wall

Hire a pro if:

- Your walls are heavily textured and require full replastering

- You’re doing an entire home exterior

- You need tall scaffolding for a second story

For more complex installations involving structural elements or siding, review:

Load-Bearing Wall Guide.

Finishing Ideas (Modern, Farmhouse, & Luxury Looks)

Board and batten is incredibly versatile. Here are popular design approaches:

1. Classic White

Bright, timeless, and works in any room.

2. Rich Dark Colors

Deep navy, charcoal, or matte black create a modern, dramatic mood.

3. Natural Wood

Leave the battens in pine or cedar and stain them. Use a clear satin polyurethane for protection.

4. Two-Tone Designs

Paint the battens a contrasting shade for visual depth.

5. High Wainscoting

Run the boards up to two-thirds of the wall for a sophisticated dining room or entryway.

If you enjoy experimenting with finishes, explore:

How to Make Plywood Look Like Oak.

Maintenance and Durability

Interior

- Light cleaning with soap and water

- Recaulk joints every few years if cracks appear

- Touch-up paint occasionally in high-traffic areas

Exterior

- Inspect annually for expansion gaps

- Repaint every 5–7 years

- Replace cracked or warped boards promptly

Final Thoughts: Why Board and Batten Is Worth Doing

Board and batten carries an almost magical combination of practicality and design impact. It adds permanent value to your home, softens plain drywall, and introduces shadow lines that make a room feel intentionally styled. It’s the type of project where a few careful decisions—spacing, paint sheen, board thickness—determine entirely the finished look. Once you get those right, the installation feels surprisingly simple.

Whether you’re upgrading a single wall or revamping an entire exterior, board-and-batten is a project that delivers visual impact every time. And once you do your first wall, you’ll understand why so many people keep going back to it.