If you’ve spent time in the lumber aisle comparing plywood sheets, you’ve probably noticed a confusing mix of letters—ACX, BCX, CDX—and wondered what they really mean. One of the most versatile and affordable types in that lineup is BCX plywood. It sits right between rough-construction grades and high-finish cabinetry panels, making it a favorite among contractors and DIYers alike.

In this guide, we’ll break down what BCX plywood is, how it’s made, where it performs best, and what to look for before buying. You’ll also find links to related plywood resources on ThePlywood.com and a few trusted retailers and Amazon picks to help you source quality panels.

What Does “BCX” Mean?

Plywood grades are based on two things: the quality of each veneer layer and the type of glue used to bond them.

- B face: The front veneer is smooth, tight-grained, and nearly free of visible defects. Small, tight knots or wood patches may appear, but the surface is easily paintable.

- C back: The back side allows more knots, color variation, or repairs. It’s not meant for show surfaces.

- X glue: The “X” stands for exposure-rated adhesive, meaning it’s suitable for exterior or semi-exterior use.

Together, BCX plywood offers a good face for visible applications, a sturdy back, and moisture-resistant bonding. This combination makes it one of the most adaptable panels on the market.

(Learn more about how plywood grades work in our Plywood Grades Explained guide.)

How BCX Plywood Is Made

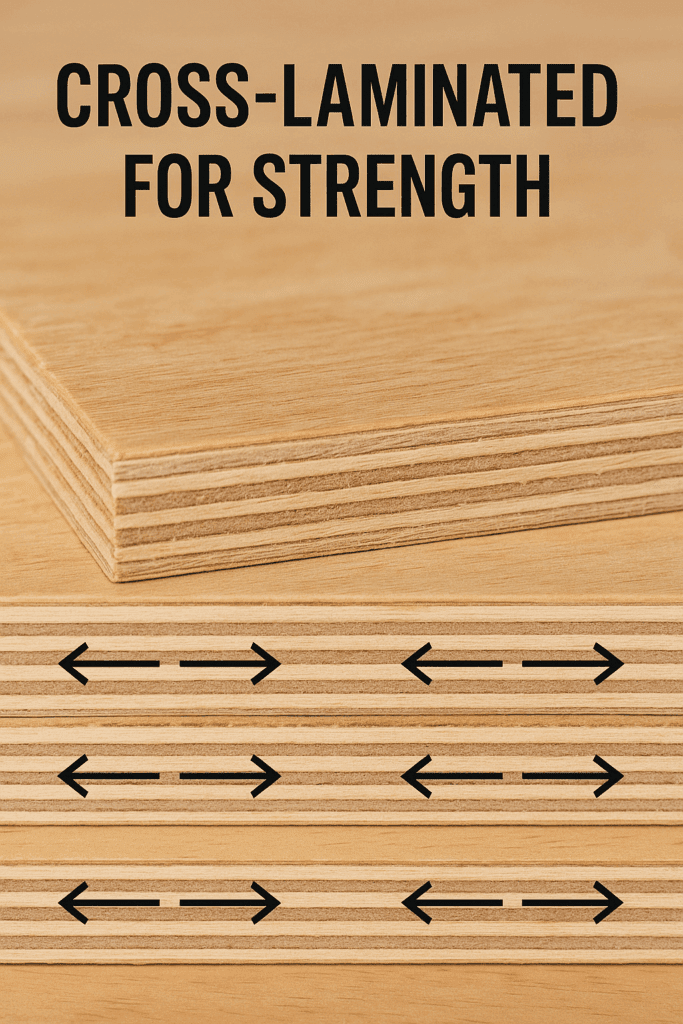

Like all plywood, BCX is made by cross-laminating thin wood veneers with their grain directions alternating at right angles. This cross-grain pattern gives the sheet strength, stability, and resistance to warping.

For BCX, manufacturers use a B-grade veneer on the face, a C-grade veneer on the back, and C- or D-grade inner plies glued with water-resistant phenolic adhesive. The finished panel is then sanded smooth on the B-side, often labeled “sanded pine” or “sanded fir.”

Most panels you’ll find are softwood species—commonly Douglas Fir or Southern Yellow Pine—ranging from ⅜ inch to ¾ inch thick and available in 4 × 8 ft sheets or smaller handy panels.

Key Benefits of BCX Plywood

1. Moisture Resistance for Outdoor and Utility Use

While BCX isn’t as waterproof as marine-grade plywood, it withstands occasional rain, humidity, and condensation without delaminating. That makes it ideal for outdoor structures with protective finishes—think sheds, exterior walls, soffits, and porch ceilings.

2. Smooth and Paintable Face

The sanded B-face takes primer and paint evenly, letting you achieve a clean finish without paying for an A-grade sheet. It’s popular for garage walls, shop cabinets, utility furniture, and built-ins where appearance still matters.

3. Balanced Cost and Quality

BCX sits in the sweet spot between rough CDX and premium ACX plywood. It’s strong enough for structural use but still affordable for larger projects. Many builders use it as a budget-friendly upgrade when they need a smoother face than CDX can provide.

4. Strong and Dimensionally Stable

Because of its cross-laminated core, BCX resists shrinkage, splitting, and cupping far better than solid lumber. Screws and nails hold securely, and edges stay firm if appropriately sealed.

Typical BCX Plywood Uses

You’ll see BCX plywood used in many everyday construction situations. It’s one of those materials that’s not fancy, but it gets the job done and holds up better than plain CDX when the finished side will actually be seen.

- Exterior wall sheathing under siding or stucco:

BCX works well as a base layer before siding goes on because it adds strength and helps the wall stay rigid. Once everything is covered, nobody will ever see it, but it’s doing the heavy lifting underneath. - Roof decking beneath shingles or metal roofing:

It provides a solid platform for roofing, helping shingles or panels sit flat and last longer. Roofers like that it doesn’t warp too easily while waiting for the weather to cooperate. - Subfloors and underlayment layers:

BCX can handle the weight of people walking, moving furniture, and everyday use. When paired with proper fastening, it prevents floors from feeling spongy. - Shed and garage construction:

It’s a reliable “use it and don’t overthink it” material for utility buildings. A coat of paint or exterior sealant goes a long way toward protecting it from humidity and rain. - Outdoor furniture frames and benches (when sealed):

The better face sands smooth enough to look good when finished. As long as it’s sealed well, it can withstand seasonal changes when left outside. - Utility shelving and shop fixtures:

It’s strong enough to hold heavy tools, boxes, or paint cans without bowing. Plus, you don’t have to worry about scratches or dents in a workshop environment. - Back panels for cabinets or workstations:

The good face gives the interior a clean, purposeful look. It keeps cabinets from racking or twisting over time. - Porch ceilings and soffits:

The smooth face paints nicely and looks finished once it’s overhead. Meanwhile, the rougher back side stays hidden where no one will ever notice.

BCX is especially handy when one side will be visible and finished, while the other is hidden behind framing.

When BCX Is the Right Choice (and When It’s Not)

If you’re looking at BCX, you’re probably trying to figure out where it fits and where it doesn’t. I’ve run into that too. Sometimes you need something nicer, like when you’re building cabinets or shelves people are actually going to see up close — that’s where Cabinet Grade Plywood Explained comes in, because it shows the difference without all the confusing jargon. And if your project is going near heat (like behind a stove or around a smoker) or outside where the weather gets weird, you’ll want to skim Heat-Resistant Plywood and Best Plywood for Outdoor Use before you spend money and end up frustrated later. I also used to guess on plywood thicknesses until I finally printed the Plywood Thickness Chart and stuck it on my shop wall. It saves so much second-guessing.

BCX vs ACX vs CDX: What’s the Difference?

Understanding plywood grading helps you buy smarter:

| Grade | Face/Back | Adhesive | Appearance | Typical Use |

|---|---|---|---|---|

| ACX | A / C | Exterior | Very smooth, minimal defects | Cabinet doors, fascia, exterior trim |

| BCX | B / C | Exterior | Smooth face, visible knots on back | Subfloors, sheds, semi-exposed projects |

| CDX | C / D | Exterior | Rough, visible knots and voids | Roof and wall sheathing |

So if your project needs a finished, paintable face but doesn’t demand perfection, BCX gives the best balance.

(Compare with our ACX vs BCX Plywood Guide for deeper details.)

When to Use BCX and When to Avoid It

Use BCX Plywood When:

- The panel may face occasional moisture or outdoor humidity.

- One side will be painted or visible, but you want to save on A-grade cost.

- You need moderate structural strength for walls, floors, or roofs.

- You’re building temporary outdoor fixtures or shop projects.

Avoid BCX Plywood When:

- The panel will be continuously exposed to water (boat hulls, planters).

- Both sides need a flawless, furniture-grade appearance.

- You require fire-rated or pressure-treated properties not offered in BCX.

For long-term outdoor durability, apply a high-quality exterior primer, paint, or polyurethane sealer.

How to Select the Right BCX Sheet

- Check the label – it should clearly say BCX Exterior or Exposure 1.

- Inspect the face veneer – minimal patches, smooth sanding, and few knots.

- Choose the right thickness – ½ inch for walls, ⅝–¾ inch for floors and roofs.

- Verify flatness – avoid warped sheets, especially if stored vertically.

- Consider species – Douglas Fir panels are slightly stiffer than pine.

- Match to application – heavier loads = thicker sheets; decorative work = lighter, sanded panels.

How to Finish and Protect BCX Plywood

Even though the adhesive is moisture-resistant, the wood itself isn’t waterproof. To extend life:

- Sand lightly with 180-grit before painting.

- Seal edges with exterior wood glue, epoxy, or polyurethane.

- Prime with oil- or latex-based primer—especially on the B-face and edges.

- Topcoat with two layers of exterior paint or clear spar urethane.

- Maintained by recoating every few years for outdoor structures.

This small effort prevents delamination and keeps your projects looking sharp season after season.

(For complete finishing steps, see our How to Paint Plywood the Right Way tutorial.)

Strength and Load Ratings

BCX plywood meets APA-rated sheathing standards, meaning it can carry significant loads when installed correctly.

Typical span ratings:

- ⅜ inch BCX — 24/0 (span rating for walls)

- ½ inch BCX — 32/16 (walls and roofs)

- ⅝–¾ inch BCX — 40/20 (subfloors and roofs)

Always follow the nailing schedule recommended by your local building code. The grain of the face should run perpendicular to the supports for maximum strength.

Cost and Availability

Prices vary by region and species

| Thickness | Typical Price Range (USD) |

|---|---|

| ⅜ in (10 mm) | $20–$25 per sheet |

| ½ in (12 mm) | $25–$35 per sheet |

| ⅝ in (15 mm) | $30–$40 per sheet |

| ¾ in (19 mm) | $40–$55 per sheet |

Local stores like Home Depot, Lowe’s, and Ace Hardware typically carry BCX sanded pine or fir panels. For online buyers, you’ll find BCX Plywood sheets and handy panels on Amazon → (affiliate-style link).

(Always check current pricing and shipping costs before ordering.)

Real-World Examples of BCX Plywood in Action

Outdoor Storage Bench

A reader built a backyard storage bench using ½-inch BCX. After sealing all edges and painting it navy blue, it held up outdoors for over five years with minimal swelling.

Garage Workstation

BCX makes excellent wall backing for a pegboard-style workstation. Its smooth face accepts screws and paint well, creating a clean look without the high price of cabinet plywood.

DIY Playhouse

For a children’s playhouse or garden shed, ⅝-inch BCX panels sheathing over 2×4 framing provide a durable, semi-smooth surface that can be painted any color.

These examples show how BCX bridges the gap between construction-grade durability and finish-grade usability.

Environmental Notes & Sustainability

Many major producers now source veneers from responsibly managed forests and certify panels under FSC or SFI standards. When possible, look for those labels on the sheet stamp.

Plywood is also more eco-efficient than solid lumber because it uses thinner veneers and smaller-diameter logs. If sustainability matters in your project planning, BCX can be a balanced option between performance and responsible sourcing.

Troubleshooting Common Issues

| Problem | Likely Cause | Quick Fix |

|---|---|---|

| Warped sheet | Improper storage or uneven humidity | Stack flat with weights ≥ 24 hours before use |

| Edge delamination | Water intrusion | Seal edges with epoxy or polyurethane before installation |

| Surface bubbling under paint | Moisture trapped in grain | Sand and re-prime with oil-based primer |

| Splintering edges | Dull blade or no tape line cut | Use a sharp plywood blade and masking tape before cutting |

Quick Takeaways

BCX plywood = B-grade front + C-grade back + exterior adhesive.

The good face sands smooth, while the back can be a little rough.

Ideal for semi-exposed projects where finish and durability both matter.

Think porch ceilings, outdoor benches, or utility cabinets.

Seal edges and paint for the best long-term performance.

The edges are where moisture likes to sneak in, so don’t skip this step.

Less expensive than ACX, smoother than CDX—a perfect middle ground.

It’s the sheet you grab when you want “presentable” without paying a premium.

Available in most home centers and online markets.

Check the stamp on the side to make sure you’re actually getting BCX, not a cheaper substitute.

Final Thoughts

BCX plywood earns its popularity by doing almost everything reasonably well. It’s not glamorous, but it’s reliable, affordable, and forgiving—a material you can trust for real-world building. Whether you’re framing a shed, lining a workshop, or building a utility bench, BCX offers a clean surface, strong core, and weather-tough glue line that make projects last.

If you treat and finish it correctly, your BCX builds can endure years of use—and with a bit of paint or sealant, they’ll look good doing it.

For more plywood comparisons, durability tests, and finishing tips, explore our full resource library at ThePlywood.com—your practical guide to every kind of engineered wood.