When I first started woodworking, plywood was just the budget-friendly go-to for garage shelves or workshop benches. But as I began taking on more serious furniture projects, I kept hearing about something called ApplePly. At first, I thought it was just another plywood brand – maybe made from applewood?

Turns out, that’s not the case. And once I actually tried it, I realized why experienced woodworkers swear by it. If you want to know how ApplePly stacks up, when to use it, and why it’s different from the plywood you find at the big box store, you’re in the right place.

🧵 What Is ApplePly?

ApplePly is a premium hardwood plywood with a strong birch veneer core. It’s made in the USA by States Industries, based in Oregon. And no—despite the name, there’s no applewood in it. The name is more about branding than content, playing off the region’s reputation for apples and the product’s clean, layered appearance.

Each sheet is built from multiple thin birch plies—far more than standard plywood—which gives ApplePly its signature strength, stability, and edge detail. You can leave the edges exposed, and they look great with just a bit of sanding and finish.

🧠 ApplePly vs. Regular Plywood

After using ApplePly and comparing it side-by-side with cheaper plywood from my local store, the differences are pretty obvious.

✅ What Makes ApplePly Special:

- 13 to 15 plys in 3/4″ sheets (vs. 5-7 in standard ply)

- Virtually no voids inside the core

- Exposed edge grain is decorative

- Stronger screw-holding power

- More dimensionally stable

- No urea-formaldehyde glue (less off-gassing)

It feels like the American answer to Baltic birch—same strength and clean finish, but made domestically.

🎒 Best Uses for ApplePly

This stuff is built for projects where appearance and structure matter. I’ve used it on:

- Floating shelves – Exposed edges, no need for banding

- Modern desks – Clean lines and flat panels

- Custom drawer boxes – Great for soft-close slides

- Workshop cabinetry – Flat, tough, and looks good

- Kids’ furniture – No formaldehyde, strong and safe

Many pros also use ApplePly for retail fixtures, architectural paneling, and stair treads. It’s especially good for modern or industrial-style builds.

ApplePly vs. Baltic Birch: Real Differences You’ll Notice

If you’re comparing ApplePly to Baltic Birch, you’re in good company. I’ve used both, and here’s what I’ve noticed firsthand:

| Feature | ApplePly | Baltic Birch |

|---|---|---|

| Core Material | All-hardwood (birch) | All-hardwood (birch) |

| Veneer Thickness | 1/16 inch | Slightly thicker (1.5mm) |

| Edge Appearance | Super clean, great for exposed | Functional but not fancy |

| Made In | USA (Oregon) | Eastern Europe/Russia |

| Common Sheet Size | 4×8 feet | 5×5 feet |

| Cost | Slightly higher | Slightly lower |

ApplePly costs a bit more, but if you’re building something where the edges show—like modern bookcases or open kitchen shelving—it’s worth every penny.

Why I Keep Choosing ApplePly

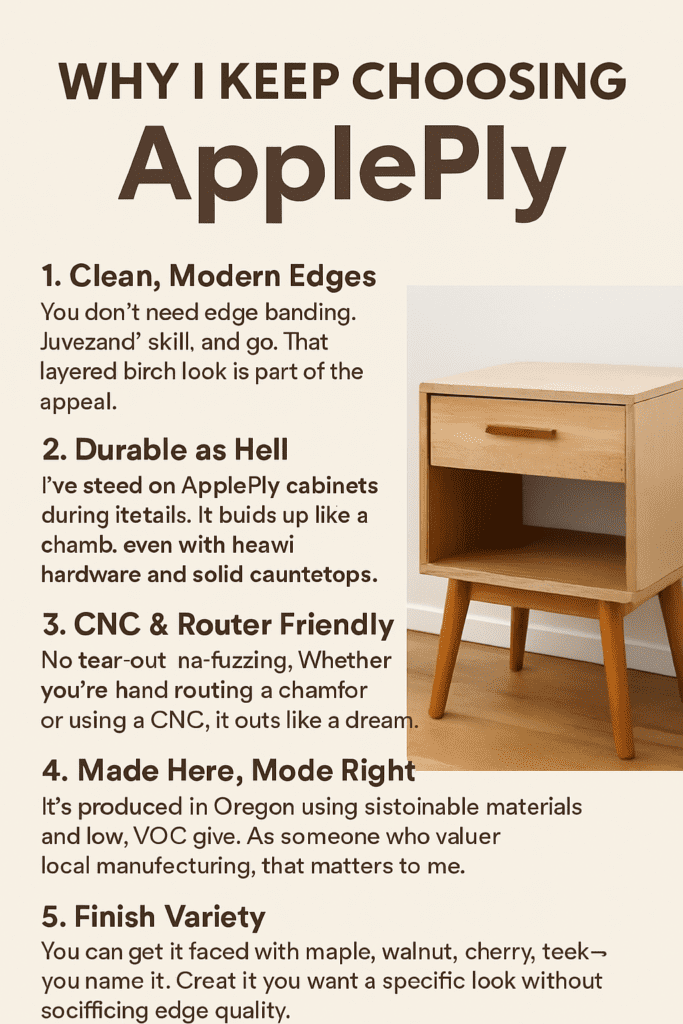

1. Clean, Modern Edges

You don’t need edge banding. Just sand, seal, and go. That layered birch look is part of the appeal—and it always gets compliments.

2. Durable as Hell

I’ve stood on ApplePly cabinets during installs. It holds up like a champ, even with heavy hardware and solid countertops. One cabinet even survived two apartment moves without a scratch.

3. CNC & Router Friendly

No tear-out, no fuzzing. I’ve run it through both my router table and a low-end CNC machine—it cuts crisp every time.

4. Made Here, Made Right

Made in Oregon with low-VOC glue and sustainably sourced birch—stuff you can actually feel good about using.

5. Finish Variety

You can get it faced with maple, walnut, cherry, teak—you name it. It’s awesome if you want a specific grain but still want that edge to shine.

Projects I’ve Used ApplePly For

- Mid-century-style nightstands with exposed edges

- CNC-cut custom drawer boxes

- Open kitchen shelving

- Slat walls for a retail display

- Workshop cabinets (because why not make your shop look sharp?)

⚖️ Pros and Cons

| ✅ Pros | ⚠️ Cons |

|---|---|

| Ultra-flat & stable | Pricier than standard ply |

| No voids or patches | Not sold at big box stores |

| Great edge appearance | Heavier compared to softwood ply |

| Formaldehyde-free glue | Shipping can be expensive |

📄 Available Thicknesses

ApplePly comes in:

- 1/4″, 3/8″, 1/2″, 5/8″, 3/4″

- Up to 1-1/2″ for specialty uses

You can also get it faced with different hardwood veneers like:

The core is always birch, but the face can match your project style.

🌟 How to Finish ApplePly (No Edge Banding Needed!)

The edges are where ApplePly really shines. Here’s my go-to method:

- Sand to 220 grit – Especially the edges

- Seal with sanding sealer like Zinsser SealCoat

- Apply a wipe-on poly – I love General Finishes

- Buff between coats with 320 grit or higher

The result is a smooth, durable surface that looks professional without any banding.

🛒 Where to Buy ApplePly

You probably won’t find ApplePly at Home Depot. Check:

- Local hardwood lumber dealers

- Cabinet supply shops

- Amazon (for small panels or specialty vendors)

- Direct distributors listed on the States Industries website

Shipping large sheets can get expensive, so it’s worth calling around locally.

🚫 Common Myths About ApplePly

- Myth: It’s made from apple trees.

— Nope. 100% birch core. - Myth: It’s just a rebranded Baltic Birch.

— Not quite. They’re similar, but ApplePly is made in the U.S., with stricter environmental and quality controls. - Myth: It’s only for commercial builders.

— It’s actually perfect for DIYers who want clean finishes without a lot of extra work.

Real Tips for Better Results

- Use a high-quality saw blade to avoid chipping on cross-cuts.

- Lightly round over exposed edges with a trim router for a clean, finished look.

- If you’re painting it (though why would you?), seal the edges first.

- Don’t overdrive screws near the edge—it’s strong but treat it like solid hardwood.

🛠️ Pro Tip: You could probably drop a bowling ball on it—though I haven’t tried.

✅ ApplePly Project Checklist (Printable)

📝 Final Thoughts

If you care about strength, consistency, and clean design, ApplePly is one of the best plywood options available. Sure, it costs more than standard panels, but for projects that matter—like furniture, built-ins, or visible cabinetry—it’s worth the upgrade.

I started using ApplePly for its aesthetics, but I keep coming back for the quality. It machines well, finishes beautifully, and the exposed edges are a bonus, not a drawback.

Give it a try, even on a small build. I guarantee you’ll notice the difference.