If you’ve ever built a cabinet or refinished a piece of furniture, you know how picky we can get about plywood. Some sheets splinter like crazy. Others just don’t take stain well. But Alder plywood? It’s one of those hidden gems that delivers a clean look and is easy to work with.

I started using Alder mostly by accident—had a sheet left over from a project, and it just worked beautifully. Since then, it’s become a go-to in my shop. Here’s why.

What Makes Alder Plywood Stand Out

- It looks great right out of the gate. Alder has a naturally warm, reddish tone with a tight, even grain that makes it easy to match with other woods. Whether you’re going for a rustic vibe or something modern and sleek, it fits in.

- It’s super easy to work with. Unlike some hardwoods, Alder machines well without chewing up your tools. It’s soft enough to sand easily but still holds its shape nicely. Just make sure your blades are sharp—dull tools will still fight back.

- Takes stain like a champ. I’ve used everything from clear finishes to dark walnut stains on Alder, and it never gives me trouble. The grain doesn’t blotch, which is a huge win if you’re trying to mimic pricier woods like cherry or maple.

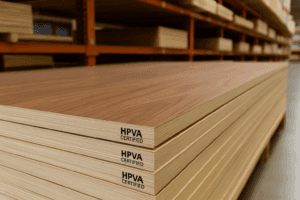

Grade Options (And What They Actually Mean)

Depending on your project, you might want a cleaner or more rustic look. Here’s how Alder grades break down in real-world terms:

- A Grade – Smooth, clean, and uniform. This is the premium stuff—perfect for high-end furniture or cabinets where the wood is the star of the show.

- B Grade – Still nice, but with a bit more natural variation. I use this for projects where I want it to look a little more organic, like bookshelves or built-ins.

- C Grade (a.k.a. Rustic) – Knots, color variation, and character galore. I actually love this for farmhouse-style pieces or accent walls. It has charm you just can’t fake.

- Quartered Cut – Straighter grain, which looks amazing on cabinet doors or drawer fronts.

- Book Matched – This one gives you mirrored patterns from the veneer slices, which can be a nice visual focal point.

Veneer Options (If You’re Going That Route)

If you’re working with veneer instead of full sheets, Alder still shines:

- You can get paper-backed or wood-backed sheets, depending on your flexibility needs.

- Some suppliers even offer peel-and-stick options, which are a total time-saver.

- Tip: It’s worth adding insurance if you’re ordering veneer online—trust me on this one.

Sizes and Thicknesses

Most places carry Alder plywood in standard 4′ x 8′ sheets, and the typical thicknesses include:

- 1/8″

- 1/4″

- 1/2″

- 3/4″

The thinner sheets usually have MDF cores, which keeps them nice and flat, while the thicker ones often use what’s called a Pro-Core (basically a combo of veneer and particleboard). It creates a smooth surface that’s great for face veneers or paint.

A Few Tips From My Shop

After using Alder on a handful of custom projects, here are a few things I’ve learned the hard way:

- Watch for veneer splintering. Alder face veneers are thin. If you’re cutting across the grain, score the top first or use painter’s tape to minimize chipping.

- Don’t use dull blades. Seriously. Alder is soft, and dull tools will tear it up fast—especially if you’re crosscutting.

- Seal it if it’s going near water. Alder doesn’t love humidity or bugs. I always add a good finish if it’s going near a kitchen or bathroom.

Where I’ve Used It

Personally, I’ve used Alder for:

- Custom cabinet doors

- Guitar body blanks

- Wall paneling in a mudroom

- A modern-style coffee table with black legs and a dark-stained top

It’s also popular in electric guitar builds—Fender used alder for a bunch of classic Stratocasters.

How It Stacks Up Against Other Woods

| Wood | Good For | Cost | Hardness |

|---|---|---|---|

| Alder | Indoor furniture, cabinets, guitars | Mid-range | 590 lbf |

| Pine | Rustic projects, basic trim | Budget | ~380–600 lbf |

| Maple | Furniture, floors, countertops | $$$ | 1,450 lbf |

| Oak | Heavy-use furniture, floors | $$ | 1,200 lbf |

Bottom line? Alder gives you the look of a premium hardwood without the price tag or the headaches.

Is Alder Budget-Friendly?

Yep. Knotty Alder is just a bit more expensive than pine, while clear Alder still comes in under most maple or cherry options. Plywood pricing is about on par with other domestic hardwood varieties, so you’re not paying a premium.

Final Thoughts

If you’re tired of fussing with plywood that chips, doesn’t stain right, or warps like crazy—give Alder a try. It’s a solid choice for furniture builders, cabinetmakers, and even DIYers like me just looking to get clean, pro-looking results without blowing the budget.

Whether you’re building a set of floating shelves or revamping your kitchen cabinets, Alder plywood might just be your new best friend in the shop.