Modern homes use trusses instead of traditional rafters because they are stronger, cheaper, and cover more expansive spaces without extra support. Trusses are factory-made, making them efficient and easy to install. However, they limit attic space unless specially designed.

Trusses are held together with gussets, metal or plywood plates connecting the wood. Plywood gussets are affordable and easy to customize. Proper installation involves cutting gussets, aligning them precisely, and securing them with glue and nails for strength.

Why Trusses Are Used in Modern Construction

Another advantage of trusses over rafter roofs is that they can cover a greater span without support. With today’s home building style, including large wide-open spaces, trusses provide a way of building without columns and supporting beams. Initially designed for putting roofs over large areas, like churches, trusses readily adapt to our modern home style, giving the homeowner a sizeable multi-use living area.

Trusses are also cheaper to manufacture and install than rafters. Since they are made on the ground in a factory, their manufacture is highly efficient. Once they arrive on site, it is much faster and easier to install the trusses on the home than it would be to build a comparable roof structure with rafters.

The one real disadvantage of trusses over rafters is that they make it extremely hard to use the attic space in the home as a living or storage area. However, trusses can be designed to provide a room in the attic surrounded by trusses. This reduces some of the advantages of using trusses, as the area where the room is needs larger cross-section floor joists and some support in the form of a supporting wall or column in the floor below the attic.

Since trusses are so popular for building homes, it is not surprising that other structures, such as garages, storage sheds, and even garden sheds, are often built with trusses. If you are going to build an addition to your home or any outbuildings, chances are you will need to build trusses for it.

Gussets in the Trusses

Trusses are made flat, as if you laid all the pieces out on the floor and then attached them. The pieces do not overlap, butting up against each other at the seams. This requires special connecting techniques, as the various pieces of the truss can’t be nailed or screwed together. Rather, some sort of gusset is used to connect the pieces, whether metal or wood.

In factory made trusses, a pierced metal plate is normally used as the gusset. Depending on the capability of the factory, the plate may be pierced in such a way that the piercings are bent perpendicular to the plate, allowing them to be used as nails. Rather than being pounded into the wooden pieces of the truss, they are pressed in by a large hydraulic press. Truss factories which do not have this sort of press may still use metal plates, but they will nail through the plates into the wood.

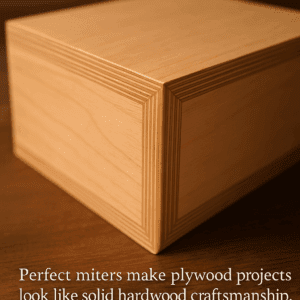

While it is possible to use metal plates for gussets in making homemade trusses, most people use plywood. Not only are plywood gussets easier to work with than metal ones, but they can also be easily customized. You are limited to the sizes available at your lumberyard when using metal plates for gussets. Then if you find that you are forced to make a design change, you have to go back to the lumberyard for different plates.

When designing roof trusses, keep in mind the maximum free span allowable by building code for the various sizes of dimensional lumber. It is important to follow these guidelines to ensure that your roof will be strong enough to handle the dead loads and live loads for the roof. In most parts of the country, roofs must be able to hold a live load of 30 lbs./sq. ft. However, in parts of the country which experience high amounts of snow, a higher live load requirement may exist. Check with your local building code enforcement office for building code requirements in your area.

Normal allowable spans:

| No. 1 Lumber Size | Max Span 16” Centers | Max Span 24” Centers |

|---|---|---|

| 2”x 4” | 9’ – 3” | 7’ – 9” |

| 2”x 6” | 13’ - 8’ | 11” – 2” |

| 2”x 8” | 17’ – 3” | 14’ – 1” |

| 2”x 10” | 21’ – 1” | 17’ – 3” |

| 2”x 12” | 24’ – 5” | 20’ |

Generally speaking, trusses made of 2”x 4” lumber can cover a distance of up to 90 feet, as long as there is no single unsupported section of the ceiling joist that is more than 9’ long. The vertical support provided by the web pieces of the truss provide adequate support for the truss, the ceiling joist and to support drywall attached to the underside of the ceiling joist.

How to Make Trusses Using Plywood Gussets

Stout plywood gussets are an excellent alternative to expensive metal gusset plates. Luckily, cutting plywood gussets for roof trusses is simple.

If you are using plans created by an architect, the first step is to choose plans for a truss system that is the right size for the building, and suitable for the loads the roof will be expected to support. However, that isn’t the only option available to you; you can design your own roof trusses or use one of the online roof truss design tools. When in doubt, choose a truss design that is stronger than you think you’ll need.

The type and thickness of plywood required will vary depending on the size of the structure and the truss design. However, for sheds and other small buildings, ½” CDX plywood is adequate. Nevertheless, never skimp! Remember that the plywood you choose will be holding your roof together when it is under strain.

The type of plywood you select is important as well. You cannot use MDF, OSB or particle board for gussets, as they do not have the right sort of strength for this application. On the other end of the spectrum, there is no reason to pay the extra expense of marine grade plywood, hardwood plywood or any of the more exotic types of plywood. Standard softwood CDX construction plywood is adequate for this task, as it will provide the necessary strength and will not normally be visible once the project is completed.

Materials and Supplies

The following list of materials and supplies is a basic one. Modify it by making additions and subtractions to suit your project’s needs.

- Lumber for trusses, cut to project plan specifications

- Plywood

- Measuring tape

- Pencil or grease marker

- Skill saw

- Construction glue

- Drill

- Nail gun (if using nails)

- Nails or screws as specified in project plans

We strongly recommend purchasing tools on the most popular sites such as: Amazon, 3M, HarborFreight, HomeDepot, AceHardware, StanleyTools, RedDevil, Sherwin-Williams…

Instructions for Cutting and Installing Plywood Gussets

Trusses are most often laid out for construction directly on a full-sized plan, helping to eliminate error and maintain consistency. It is important that all the trusses for a project be exactly the same size, in order to prevent waviness in the roof. Even slight differences in adjacent trusses will be extremely obvious in the finished roof.

You will need a perfectly flat place to build your trusses, where they can be laid out. This can either be your garage floor, driveway, the floor of the building you are constructing the trusses for or a couple of pieces of plywood that you have joined together. Just as long as the surface is large enough to lay out the entire truss and it is flat, it will work. Double check it for flatness, so that you don’t end up with a twist in your truss.

- On a single piece of plywood, measure and outline a single gusset plate according to the plans you are following. This will be your template.

- With the skill saw, carefully cut the template.

- Most trusses call for a few different shaped gussets. Repeat step one and two for each gusset shape you will be cutting. Remember that you will need two complete sets of gussets for each truss you build, as they have to be mounted to both sides of the rafter.

- On a flat, level surface such as a concrete pad, lay out lumber for a single truss, ensuring it follows the design plan exactly. Lay your gusset templates out on the truss to be sure that they are a perfect fit. If not, make necessary adjustments and double check to ensure proper fit.

- If possible, use chalk to draw the outline of the finished truss so that you can use it as a template. This will speed up the production process.

- Leave the lumber for the truss configured in place, while cutting the gussets for your trusses, if possible. This will save you a little time later in the process.

- Lay your gusset templates out on the plywood, configuring them to get the maximum amount of gussets per sheet and ensure minimal waste. Carefully draw each gusset outline, and then use the skill saw to cut as many plywood gussets as you need for your project. It is a good idea to keep the gussets organized by type to avoid confusion later. In some cases, two different gussets may appear similar enough so as to cause confusion. If it’s going to be a while before you can finish making the trusses, consider labeling the gussets.

- Mark each gusset for pre-drilling. Be sure to follow the pattern and spacing recommended on the plans you are following.

- Pre-drill the gussets, if you are nailing them by hand. This will make it easier to attach them to the trusses. Be sure to pre-drill with a bit in a smaller size than the nails or screws you’ll be using to build your trusses.

- Come back to the truss pattern you laid out, bringing a set of gussets with you.

- To fasten a gusset to a truss, start by applying a layer of construction glue to the joint you are working on. There are several brands available. Follow the manufacturer’s instructions for glue application.

- After gluing each gussets onto the truss, nail it into place or fasten it to the truss with a nail gun. The pre-drilled holes will make it easier to align and start your nails, if you are nailing by hand.

- When you’ve installed all the gussets to the first side, turn the truss over, being careful not to break any of the trusses. Then attach gussets to the other side of the joints. Be sure to align them with the first set of plywood gussets. Because you pre-drilled the holes after cutting the gussets, you won’t have to worry about whether you used the same spacing and number of nails or screws that were on the first side. All of your trusses will look exactly alike, so your finished project looks fantastic.

- Repeat steps 10-12 until all of your trusses are complete.

Once the glue has dried for the appropriate amount of time, your trusses will be ready to install. Be sure to keep them in a dry, protected place until you are ready to move on with the next phase of your project.

Plywood Gusset Nailing Pattern

Plywood gussets are nailed in place with 6d – 2” long common box nails. If you are using an air nailer, then you’ll want 2” nails. Longer nails would come out the other side of the dimensional lumber being used to make the truss, making it extremely difficult to attach the gusset on the other side.

These nails are typically put every 3” apart, staggered, so that they are not all running in a straight line, which would be more likely to split the wood they are going into. By staggering the nails, the clamping force is spread over a larger area, which will help with the adhesion of the construction adhesive used in mounting the gussets to the truss.

Another option is to use a pattern of two nails wide interspersed with one on the centerline. This pattern provides for more nails into the wood, strengthening the joint. It is essential that at minimum of three nails go into each of the dimensional lumber pieces, for stability.